P1C03-71 Battery Cooling Valve Stuck

| caution | Before replacing the ECU, ensure that the CAN bus lines is normal. |

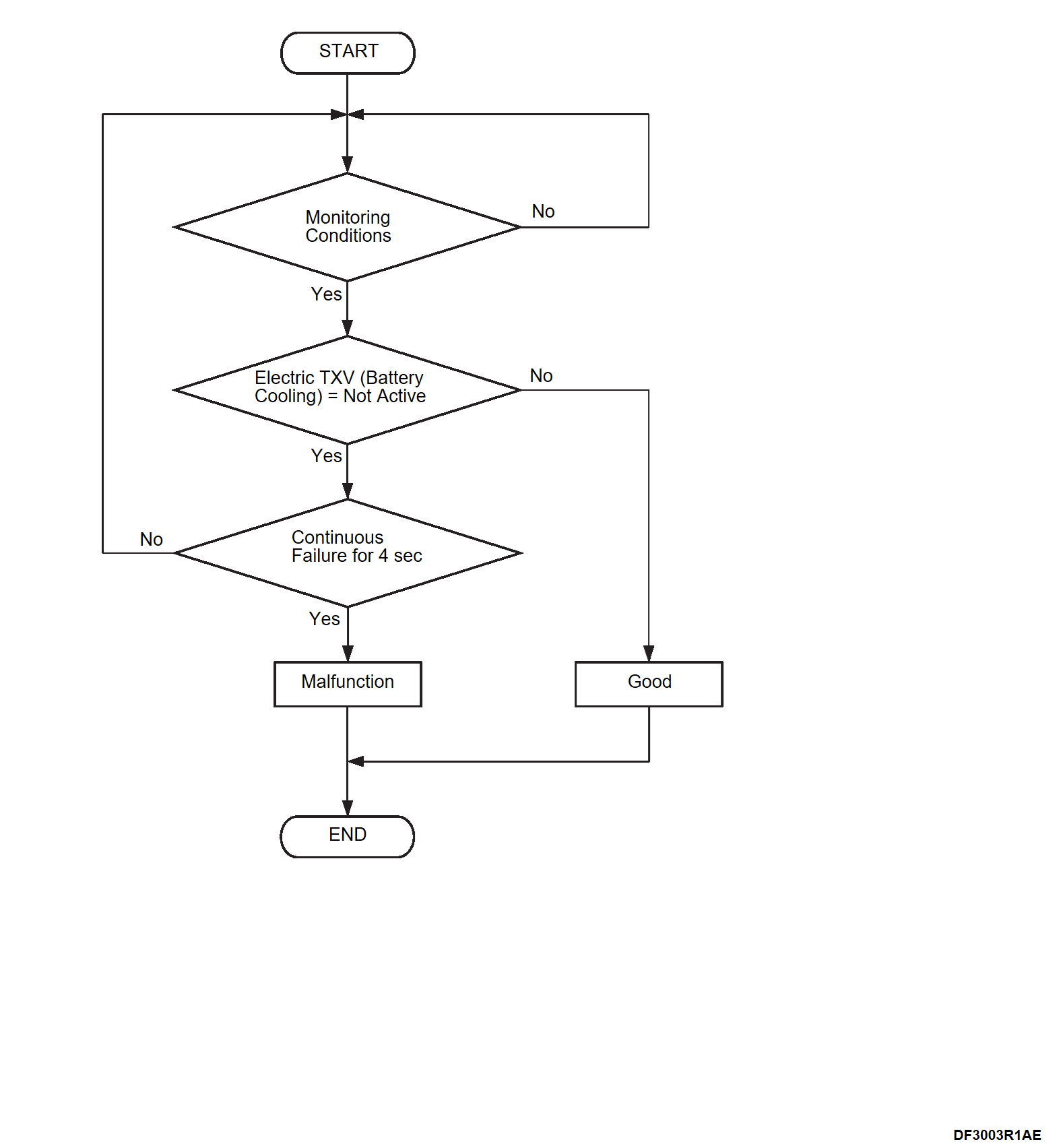

MONITOR EXECUTION

Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

TROUBLE JUDGMENT

Check Condition

- The heater PHEV A/C amp. power supply voltage is between 10 and 16 volts.

Judgment Criterion

- Failure in the expansion valve (for battery cooling) circuit is detected for 4 seconds or more.

OBD-II DRIVE CYCLE PATTERN

- Refer to OBD-II Drive Cycle – Pattern 5 OBD-II DRIVE CYCLE

.

.

PROBABLE CAUSES

- Malfunction of harness and connectors

- Malfunction of expansion valve (for battery cooling)

- Malfunction of PHEV A/C amp.

DIAGNOSIS PROCEDURE

1.Check the drive circuit voltage of the expansion valve (for battery cooling)

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Change the power supply mode of the electric motor switch to ON (READY indicator: ON).

(3) Measure the voltage between the PHEV A/C amp. connector (B_Exp_A1, B_Exp_A2, B_Exp_B1, B_Exp_B2) and body ground.

OK : 1 V or less

Is the inspection result normal?

Repair harness or connector.

Repair harness or connector.2.Check the drive circuit voltage of the expansion valve (for battery cooling)

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Change the power supply mode of the electric motor switch to ON (READY indicator: ON).

(3) Measure the voltage between the PHEV A/C amp. connector (B_Exp_A1, B_Exp_A2, B_Exp_B1, B_Exp_B2) and body ground.

OK : 1 V or less

Is the inspection result normal?

Repair or replace the harness or connector on the outside of the drive battery.

Repair or replace the harness or connector on the outside of the drive battery.3.Check of short to ground circuit in drive circuit of the expansion valve (for battery cooling)

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the continuity between the PHEV A/C amp. connector (B_Exp_A1, B_Exp_A2, B_Exp_B1, B_Exp_B2) and body ground.

OK : No continuity

Is the inspection result normal?

Repair harness or connector.

Repair harness or connector.4.Check of open/short to ground circuit in drive circuit of the expansion valve (for battery cooling)

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the continuity between the PHEV A/C amp. connector (B_Exp_A1 terminal) and (B_Exp_B1 terminal).

OK : No continuity

(3) Check the continuity between the PHEV A/C amp. connector (B_Exp_A1 terminal) and (B_Exp_A2 terminal) or (B_Exp_B1 terminal) and (B_Exp_B2 terminal).

OK : No continuity (8.0 – 10.0 Ω : At 20°C)

Is the inspection result normal?

Repair harness or connector.

Repair harness or connector.5.Check the expansion valve (for battery cooling)

Check the expansion valve (for battery cooling).EXPANSION VALVE (FOR BATTERY COOLING) CHECK .

. Repair or replace based on the inspection result of the expansion valve (for battery cooling).

Repair or replace based on the inspection result of the expansion valve (for battery cooling).

.

.Is the inspection result normal?

Repair or replace based on the inspection result of the expansion valve (for battery cooling).

Repair or replace based on the inspection result of the expansion valve (for battery cooling).6.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle - Pattern 5 OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

Replace PHEV A/C amp. Refer to Removal and Installation

Replace PHEV A/C amp. Refer to Removal and Installation . then

. then

The trouble can be an intermittent malfunction. Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

The trouble can be an intermittent malfunction. Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS .

.7.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle - Pattern 5 OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

Replace drive battery cooler pipe assembly. Refer to DRIVE BATTERY COOLER PIPE ASSEMBLY REMOVAL AND INSTALLATION

Replace drive battery cooler pipe assembly. Refer to DRIVE BATTERY COOLER PIPE ASSEMBLY REMOVAL AND INSTALLATION .

. INSPECTION END

INSPECTION END![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)