Removal and Installation

REMOVAL

| caution |

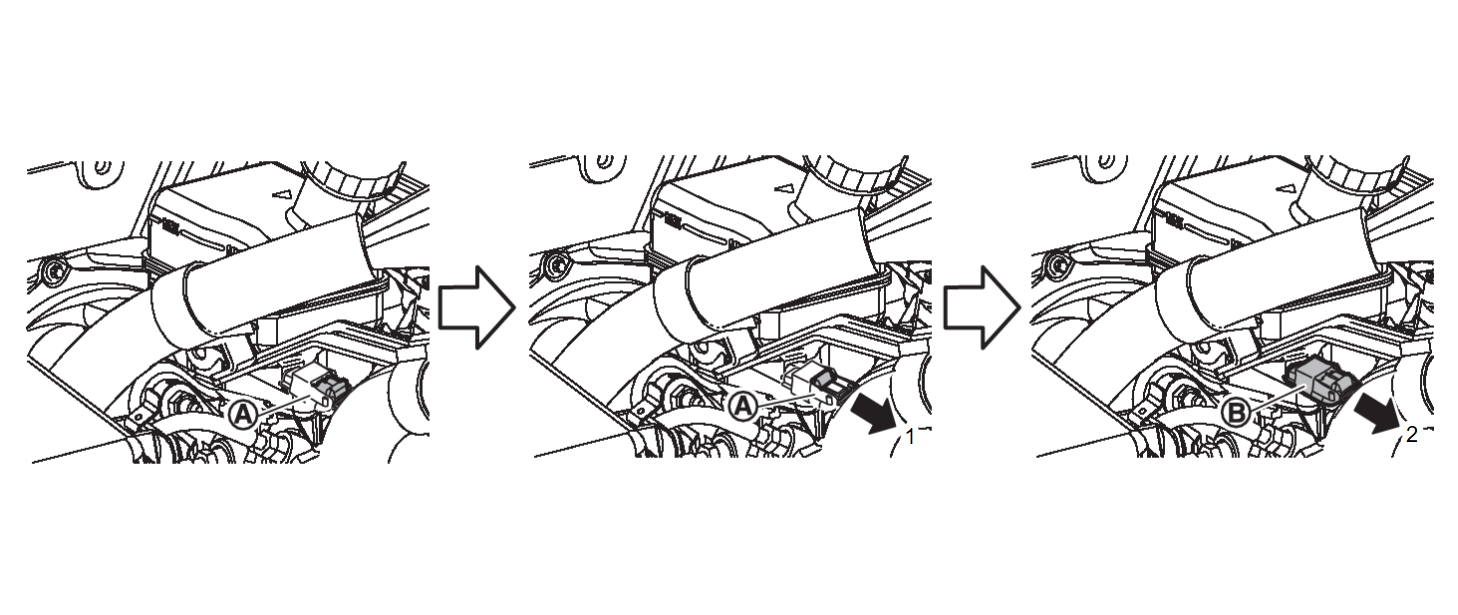

|

1. Perform inspection before removal. Refer to Refer to Inspection .

.

.

.2. Drain brake fluid. Refer to DrainingDraining .

.

.

.3. Disconnect the brake fluid level switch harness connector. Refer to following.

4. Remove the cowl top panel. Refer to REMOVAL AND INSTALLATION .

.

.

.5. Remove the power drive unit. Refer to POWER DRIVE UNIT REMOVAL AND INSTALLATION .

.

.

.6. Secure the work space by fixing the fuel hose and canister hose with ropes.

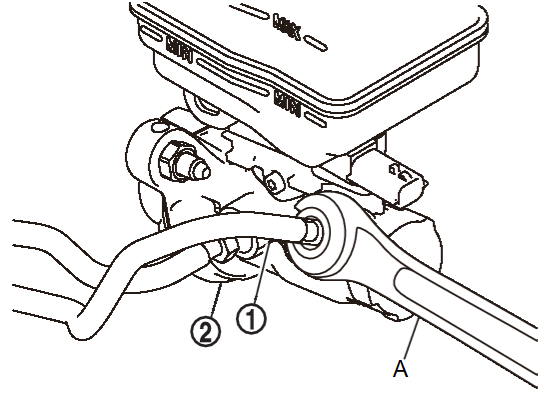

7. Separate the brake tube  from the master cylinder assembly

from the master cylinder assembly  with a flare nut wrench (A).

with a flare nut wrench (A).

from the master cylinder assembly

from the master cylinder assembly  with a flare nut wrench (A).

with a flare nut wrench (A).| caution | Never scratch the flare nut and the brake tube. |

8. Remove the master cylinder assembly.

| caution |

|

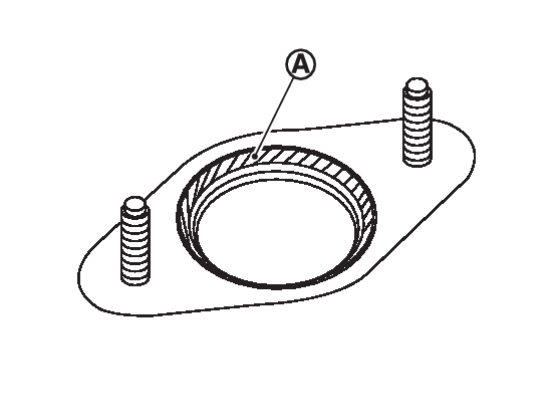

9. Remove the O-ring.

INSTALLATION

| caution | Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water. |

Note the following, and install in the reverse order of removal.

- Never reuse the O-ring.

- Never depress the brake pedal after the master cylinder assembly is removed.

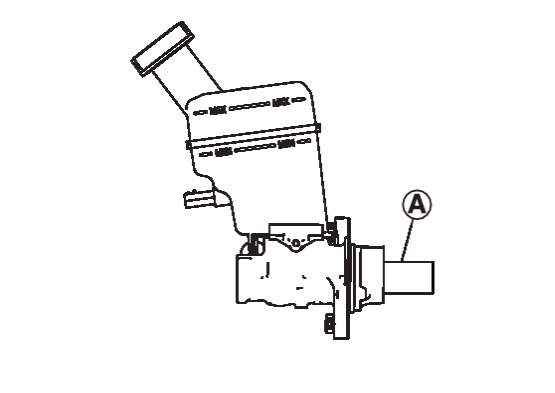

- Apply polyglycol ether based lubricant to the brake booster [see

in the figure] when installing the master cylinder assembly to the brake booster.

in the figure] when installing the master cylinder assembly to the brake booster. - The piston

of the master cylinder assembly is exposed. Never damage it when handling the master cylinder.

of the master cylinder assembly is exposed. Never damage it when handling the master cylinder. - Check that no dirt and dust are present on the piston before installation. Clean it with new brake fluid if necessary.

- The piston may drop off when pulled strongly. Never hold the piston. Hold the cylinder body when handling the master cylinder assembly.

- Never deform or bend the brake tubes.

- Temporarily tighten the brake tube

flare nut to the master cylinder assembly

flare nut to the master cylinder assembly  by hand. Then tighten it to the specified torque with a flare nut torque wrench (A). Refer to Exploded View

by hand. Then tighten it to the specified torque with a flare nut torque wrench (A). Refer to Exploded View .

. - Perform the air bleeding. Refer to Bleeding Brake System

.

. - Perform inspection after installation. Refer to Inspection

.

.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

forward of the vehicle (2).

forward of the vehicle (2).