DTC Diagnosis Procedure

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect EVAP canister purge volume control solenoid valve harness connector.

- Turn ignition switch ON.

- Check the voltage between EVAP canister purge volume control solenoid valve harness connector and ground.

+ − Voltage EVAP canister purge volume control solenoid valve Connector Terminal F16 2 Ground Battery voltage

Is the inspection result normal?

2.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between EVAP canister purge volume control solenoid valve harness connector and IPDM E/R harness connector.

+ − Continuity EVAP canister purge volume control solenoid valve IPDM E/R Connector Terminal Connector Terminal F16 2 F35 73 Existed - Also check harness for short to ground.

Is the inspection result normal?

Perform the trouble diagnosis for power supply circuit.

Perform the trouble diagnosis for power supply circuit. Repair or replace error-detected parts.

Repair or replace error-detected parts.3.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP canister purge volume control solenoid valve harness connector and ECM harness connector.

+ − Continuity EVAP canister purge volume control solenoid valve ECM Connector Terminal Connector Terminal F16 1 F52 126 Existed - Also check harness for short to power.

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.4.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

- Disconnect EVAP control system pressure sensor harness connector.

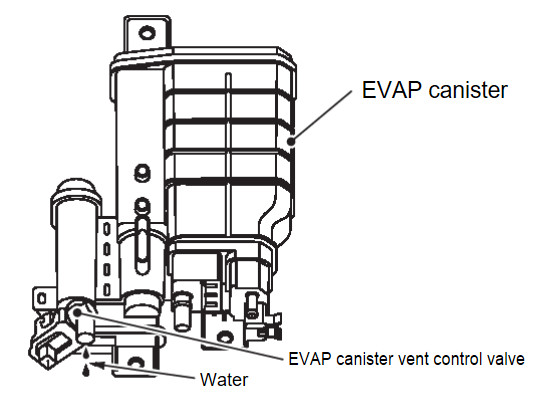

- Check connectors for water.

Water should not exist.

Is the inspection result normal?

GO TO 5Work Flow

GO TO 5Work Flow .

. Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

.5.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With M.U.T.-III SE

With M.U.T.-III SE- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Start engine.

- Perform "PURG VOL CONT/V" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE. Check that engine speed varies according to the valve opening.

Is the inspection result normal?

6.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to Component Inspection .

. Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

.

.

.Is the inspection result normal?

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

.7.CHECK RUBBER TUBE FOR CLOGGING

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

Is the inspection result normal?

Clean the rubber tube using an air blower.

Clean the rubber tube using an air blower.8.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the EVAP canister vent control valve. Refer to Component Inspection .

. Replace EVAP canister vent control valve. Refer to Removal and Installation

Replace EVAP canister vent control valve. Refer to Removal and Installation .

.

.

.Is the inspection result normal?

Replace EVAP canister vent control valve. Refer to Removal and Installation

Replace EVAP canister vent control valve. Refer to Removal and Installation .

.9.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

- Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

- Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

.10.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor attached. Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

.

The weight should be less than 2.3 kg (5.1 lb).

Is the inspection result normal?

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

.11.DETECT MALFUNCTIONING PART

Check the following. Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. Repair hose or replace EVAP canister. Refer to Removal and Installation

Repair hose or replace EVAP canister. Refer to Removal and Installation .

.

- EVAP canister for damage

- EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

Is the inspection result normal?

Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. Repair hose or replace EVAP canister. Refer to Removal and Installation

Repair hose or replace EVAP canister. Refer to Removal and Installation .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)