Inspection

INSPECTION AFTER REMOVAL

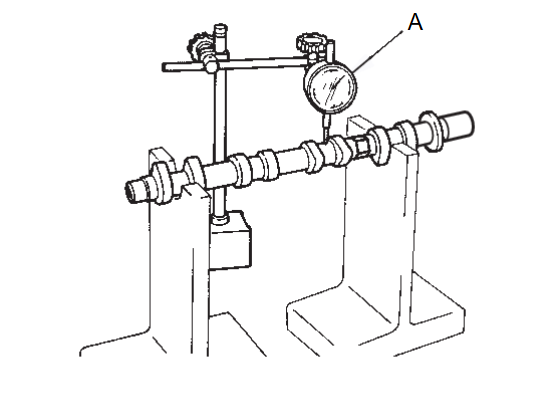

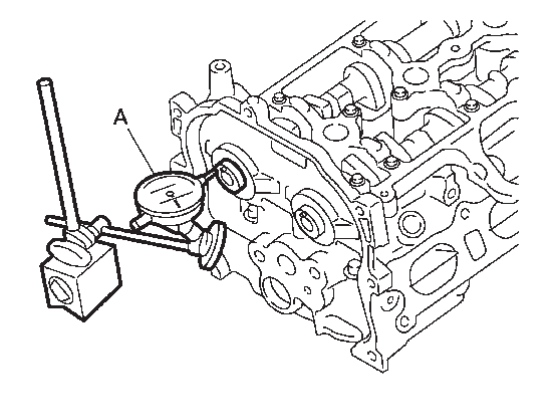

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 5 journal of camshaft.

| caution | Never support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter from the other four locations. |

2. Set dial indicator (A) vertically to No. 3 journal.

3. Turn camshaft to one direction with hands, and measure the camshaft runout on dial indicator. (Total indicator reading)

Standard: Refer to Camshaft . . |

4. If out of the standard, replace camshaft.

Camshaft Cam Height

2. If it exceeds the limit, replace camshaft.

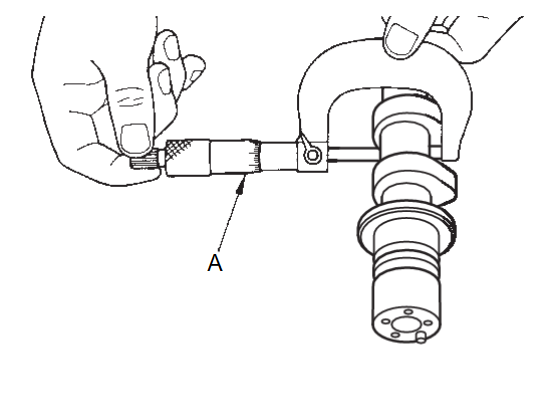

Camshaft Journal Oil Clearance

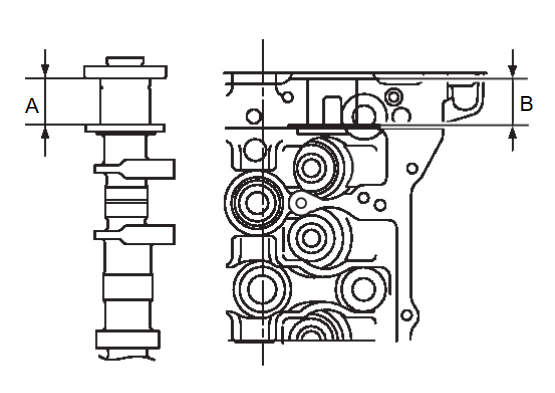

CAMSHAFT JOURNAL DIAMETER

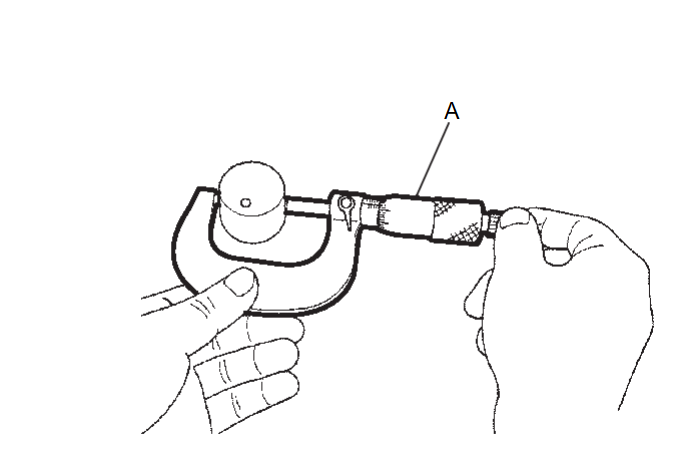

Measure the outer diameter of camshaft journal with a micrometer (A).

Standard: Refer to Camshaft . . |

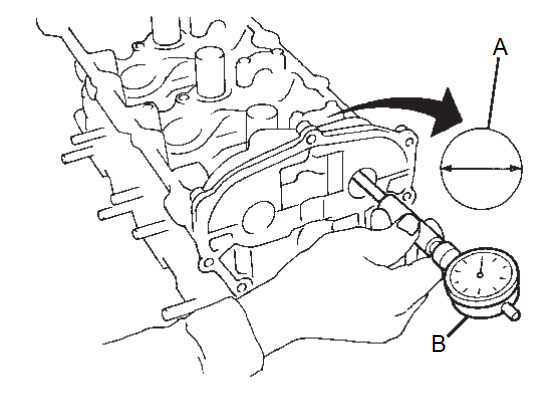

CAMSHAFT BRACKET INNER DIAMETER

- Tighten camshaft bracket bolts with specified torque. Refer to Removal and Installation

.

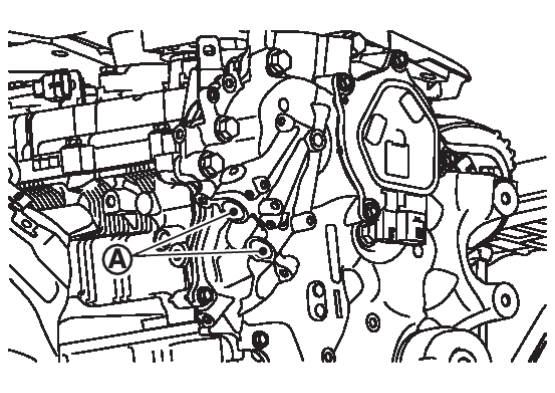

. - Measure the inner diameter (A) of camshaft bracket with a cylinder gauge (B).

Standard: Refer to Camshaft  .

.

CAMSHAFT JOURNAL OIL CLEARANCE

- (Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

Standard : Refer to Camshaft  .

. - If out of the standard, replace either or both camshaft and cylinder head.

note Camshaft bracket cannot be replaced as a single part, because it is machined together with cylinder head. Replace whole cylinder head assembly.

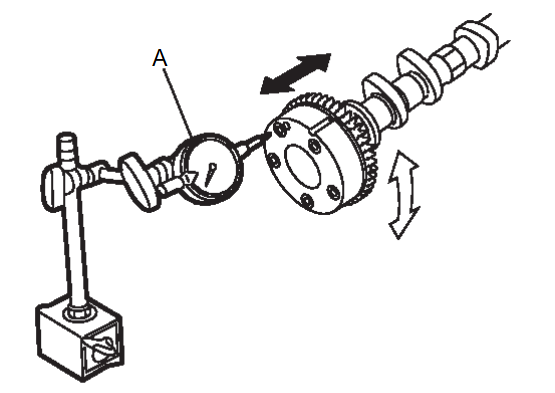

Camshaft End Play

1. Install camshaft in cylinder head. Refer to Removal and Installation .

.

.

.2. Install dial indicator (A) in thrust direction on front end of camshaft. Read the end play of dial indicator when camshaft is moved forward/backward (in direction to axis).

Standard : Refer to Camshaft . . |

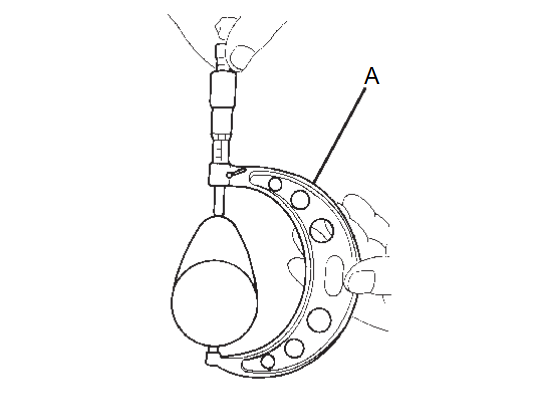

Camshaft Sprocket Runout

1. Install the camshaft in the cylinder head.

2. Install the camshaft sprocket on the camshaft.

3. Measure the camshaft sprocket runout with a dial indicator (A). (Total indicator reading)

Limit : Refer to Camshaft . . |

- If it exceeds the limit, replace camshaft sprocket.

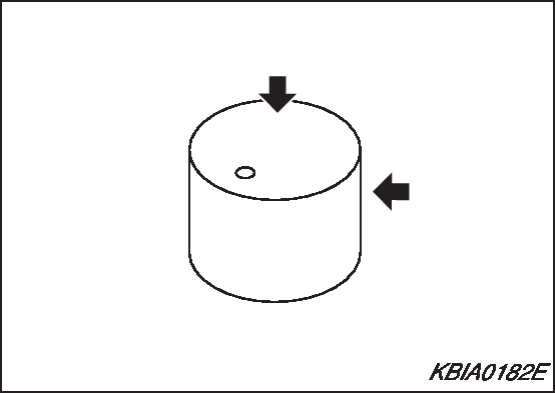

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

- If anything of the above is found, replace valve lifter. Refer to Camshaft

.

.

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

- Measure the outer diameter of valve lifter with a micrometer (A).

Standard: Refer to Camshaft  .

.

VALVE LIFTER HOLE DIAMETER

Measure the diameter of valve lifter hole of cylinder head with an inside micrometer (A).

Standard: Refer to Camshaft . . |

VALVE LIFTER CLEARANCE

- (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

Standard: Refer to Camshaft  .

. - If out of the standard, referring to the each standard of valve lifter outer diameter and valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (EXH) Oil Groove.

| warning | Check when engine is cold so as to prevent burns from any splashing engine oil. |

| caution |

|

1. Check the engine oil level. Refer to Inspection .

.

.

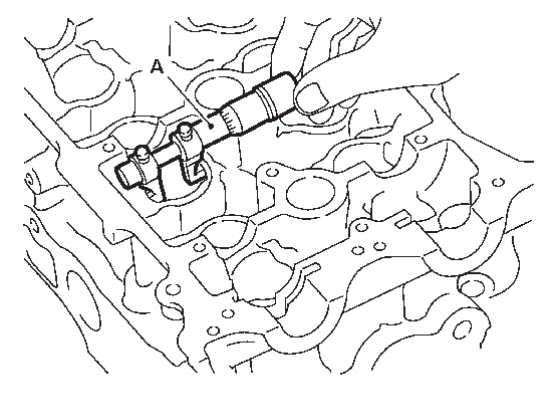

.2. Remove the exhaust valve timing intermediate lock control solenoid valve, exhaust valve timing control solenoid valve. Refer to Removal and Installation .

.

.

.3. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

(1) Release fuel pressure. Refer to Work ProcedureWork Flow .

.

.

.(2) Disconnect ignition coil and injector harness connectors.

4. Remove intake valve timing control solenoid valve. Refer to Removal and Installation .

.

.

. 5. Crank the engine, and then check that engine oil comes out from intake valve timing control cover oil hole  . End crank after checking.

. End crank after checking.

. End crank after checking.

. End crank after checking.| warning | Be careful not to touch rotating parts (drive belt, idler pulley, and crankshaft pulley, etc.). |

| caution | Engine oil may squirt from intake valve timing control solenoid valve installation hole during cranking. Use a shop cloth to prevent the engine components and the vehicle. Do not allow engine oil to get on rubber components such as drive belt or engine mount insulators. Immediately wipe off any splashed engine oil. |

6. If engine oil does not come out from valve timing control holes, diagnose problem in lubrication circuit such as dirty oil groove between oil strainer and exhaust valve timing intermediate lock control solenoid valve or exhaust valve timing control solenoid valve.Refer to Engine Lubrication System .

.

.

. 7. Remove components between exhaust valve timing intermediate lock control solenoid valve or exhaust valve timing control solenoid valve and camshaft sprocket (EXH) (if necessary) and then check each oil groove for clogging.

- Clean oil groove if necessary. Refer to Engine Lubrication System

.

.

8. After inspection, install removed parts.

Inspection for Leakage

The following are procedures for checking fluid leakage, lubricant leakage, and exhaust gas leakage.

- Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer toInspection.

- Use procedure below to check for fuel leakage:

- Place ignition switch in the “ON” position (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leakage at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

- Run engine to check for unusual noise and vibration.

note If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may generate a pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise will stop after hydraulic pressure rises. - Warm up engine thoroughly to check that there is no leakage of fuel, or any oil/fluids including engine oil and engine coolant.

- Bleed air from lines and hoses of applicable lines, such as in cooling system.

- After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.Summary of the inspection items:

Items Before starting engine Engine running After engine stopped Engine coolant Level Leakage Level Engine oil Level Leakage Level Transmission / transaxle fluid AT & CVT Models Leakage Level / Leakage Leakage MT Models Level / Leakage Leakage Level / Leakage Other oils and fluids* Level Leakage Level Fuel Leakage Leakage Leakage Exhaust gases — Leakage — *: Power steering fluid, brake fluid, etc.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)