DTC Diagnosis Procedure

1.CHECK DTC PRIORITY

If DTC P0441 is displayed with other DTC, first perform the trouble diagnosis for other DTC. Perform diagnosis of applicable. Refer to DTC Index

Perform diagnosis of applicable. Refer to DTC Index .

.

Is applicable DTC detected?

Perform diagnosis of applicable. Refer to DTC Index

Perform diagnosis of applicable. Refer to DTC Index .

. 2.CHECK EVAP CANISTER

- Turn ignition switch OFF.

- Check EVAP canister for cracks.

Is the inspection result normal?

-1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

. Replace EVAP canister. Refer to Removal and Installation

Replace EVAP canister. Refer to Removal and Installation .

. 3.CHECK PURGE FLOW

WITH M.U.T.-III SE

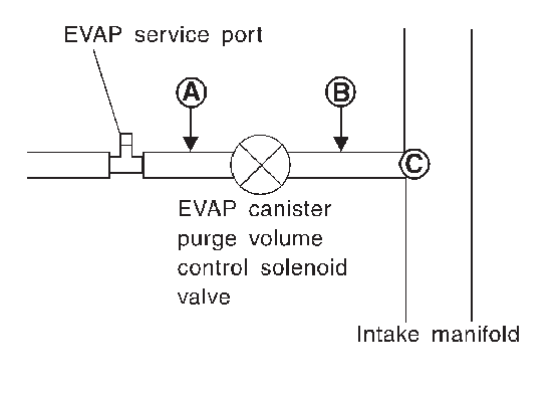

WITH M.U.T.-III SE- Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP service port.

- Start engine and let it idle.

- Select "PURG VOL CONT/V" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE.

- Adjust "PURG VOL CONT/V" opening and check vacuum existence.

PURG VOL CONT/V Vacuum 100% Existed 0% Not existed

Is the inspection result normal?

4.CHECK PURGE FLOW

WITHOUT M.U.T.-III SE

WITHOUT M.U.T.-III SE- Start engine and warm it up to normal operating temperature.

- Stop engine.

- Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP service port and install vacuum gauge. For the location of EVAP service port, Refer to System Description

.

. - Start engine and let it idle.Never depress accelerator pedal even slightly.

- Check vacuum gauge indication before 60 seconds pass after starting engine.

Vacuum should not exist. - Rev engine up to 2,000 rpm after 100 seconds pass after starting engine.

Vacuum should exist.

Is the inspection result normal?

5.CHECK EVAP PURGE LINE

- Turn ignition switch OFF.

- Check EVAP purge line for improper connection or disconnection.Refer to System Description

.

.

Is the inspection result normal?

Repair EVAP purge line.

Repair EVAP purge line.6.CHECK EVAP PURGE HOSE AND PURGE PORT

- Disconnect purge hoses connected to EVAP service port

and EVAP canister purge volume control solenoid valve

and EVAP canister purge volume control solenoid valve  .

. - Blow air into each hose and EVAP purge port

.

. - Check that air flows freely.

Is the inspection result normal?

-1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

. Repair or clean hoses and/or purge port.

Repair or clean hoses and/or purge port.7.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

WITH M.U.T.-III SE

WITH M.U.T.-III SE- Start engine.

- Perform "PURG VOL CONT/V" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE. Check that engine speed varies according to the valve opening.

Does engine speed vary according to the valve opening?

8.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to Component Inspection .

.  Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

.

.

. Is the inspection result normal?

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location

Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location .

. 9.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

- Disconnect EVAP control system pressure sensor harness connector.

- Check that water is not inside connectors.

Is the inspection result normal?

Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. 10.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR FUNCTION

DTC Description for DTC P0452, DTC Description

for DTC P0452, DTC Description for DTC P0453.

for DTC P0453. Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

.

for DTC P0452, DTC Description

for DTC P0452, DTC Description for DTC P0453.

for DTC P0453.Is the inspection result normal?

Replace EVAP control system pressure sensor. Refer to Removal and Installation

Replace EVAP control system pressure sensor. Refer to Removal and Installation .

. 11.CHECK RUBBER TUBE FOR CLOGGING

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

Is the inspection result normal?

Clean the rubber tube using an air blower.

Clean the rubber tube using an air blower.12.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the EVAP canister vent control valve. Refer to Component Inspection .

.  Replace EVAP canister vent control valve. Refer to Removal and Installation

Replace EVAP canister vent control valve. Refer to Removal and Installation .

.

.

. Is the inspection result normal?

Replace EVAP canister vent control valve. Refer to Removal and Installation

Replace EVAP canister vent control valve. Refer to Removal and Installation .

. 13.CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe and rubber tube). Check for evidence of leaks. Repair or replace malfunctioning part.

Repair or replace malfunctioning part.

Refer to System Description .

.

.

. Is the inspection result normal?

Repair or replace malfunctioning part.

Repair or replace malfunctioning part.15.CHECK INTERMITTENT INCIDENT

Perform Refer to Intermittent IncidentIntermittent Incident .

.

.

. : INSPECTION END

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)