DTC Diagnosis Procedure

1.CHECK GROUND CONNECTION

Check the following. Repair or replace error-detected parts.

Repair or replace error-detected parts.

- Connection condition of the ground E9.

- Connection condition of the ground harness between engine assembly and vehicle body (If equipped).

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.2.CHECK FOR INTAKE AIR LEAK AND PCV HOSE

- Start engine and run it at idle speed.

- Listen for the sound of the intake air leak.

- Check PCV hose connection.

Is intake air leak detected?

Discover air leak location and repair.

Discover air leak location and repair.3.CHECK FOR EXHAUST SYSTEM CLOGGING

Stop engine and visually check exhaust tube, three way catalyst and muffler for dents. -1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

. Repair or replace it.

Repair or replace it.

Is the inspection result normal?

-1With M.U.T.-III SE:

-1With M.U.T.-III SE:  .

. -2Without M.U.T.-III SE:

-2Without M.U.T.-III SE:  .

. Repair or replace it.

Repair or replace it.4.PERFORM POWER BALANCE TEST

With M.U.T.-III SE

With M.U.T.-III SE- Start engine.

- Perform "POWER BALANCE" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE.

- Make sure that each circuit produces a momentary engine speed drop.

Is the inspection result normal?

5.CHECK FUNCTION OF FUEL INJECTOR

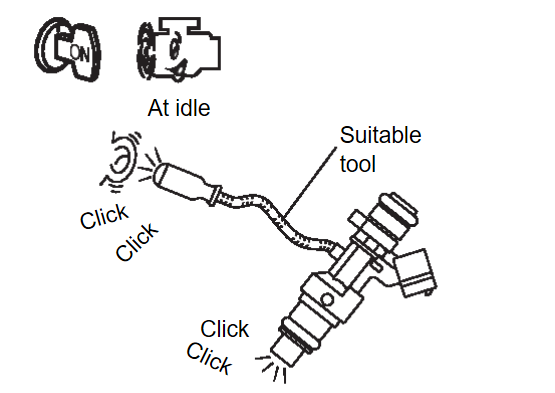

- Start engine and let engine idle.

- Listen to each fuel injector operating sound.

Clicking noise should be heard.

Is the inspection result normal?

Perform trouble diagnosis for FUEL INJECTOR. Refer to Diagnosis Procedure

Perform trouble diagnosis for FUEL INJECTOR. Refer to Diagnosis Procedure .

.6.CHECK FUNCTION OF IGNITION COIL-1

| caution | Do the following procedure in the place where ventilation is good without the combustible. |

- Turn ignition switch OFF.

- Remove fuel pump fuse in IPDM E/R to release fuel pressure.

note Do not use M.U.T.-III SE to release fuel pressure, or fuel pressure applies again during the following procedure. - Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

- Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

- Remove ignition coil and spark plug of the cylinder to be checked.

- Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

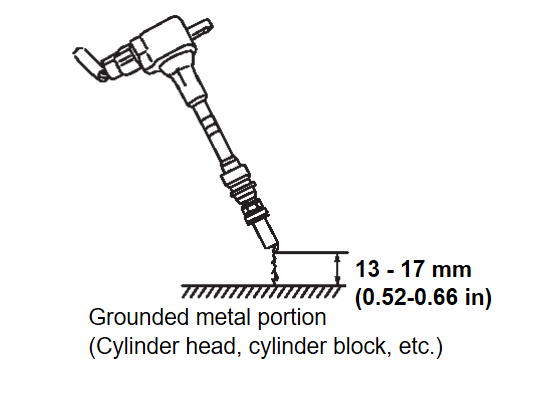

- Connect spark plug and harness connector to ignition coil.

- Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal portion as shown in the figure.

- Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated. caution - Do not approach to the spark plug and the ignition coil within 50 cm (19.7 in). Be careful not to get an electrical shock while checking, because the electrical discharge voltage becomes 20 kV or more.

- It might cause to damage the ignition coil if the gap of more than 17 mm (0.66 in) is taken.

note When the gap is less than 13 mm (0.52 in), the spark might be generated even if the coil is malfunctioning.

Is the inspection result normal?

7.CHECK FUNCTION OF IGNITION COIL-2

- Turn ignition switch OFF.

- Disconnect spark plug and connect a known-good spark plug.

- Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated.

Is the inspection result normal?

Check ignition coil, power transistor and their circuits. Refer to Component InspectionComponent Inspection (Ignition Coil with Power Transistor)

Check ignition coil, power transistor and their circuits. Refer to Component InspectionComponent Inspection (Ignition Coil with Power Transistor) .

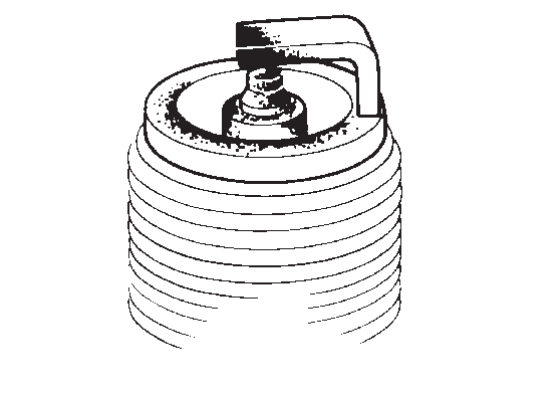

.8.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc. Replace spark plug(s) with standard type one(s). For spark plug type, refer to InspectionInspection

Replace spark plug(s) with standard type one(s). For spark plug type, refer to InspectionInspection .

.

Is the inspection result normal?

Replace spark plug(s) with standard type one(s). For spark plug type, refer to InspectionInspection

Replace spark plug(s) with standard type one(s). For spark plug type, refer to InspectionInspection .

.9.CHECK FUNCTION OF IGNITION COIL-3

- Reconnect the initial spark plugs.

- Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded portion.

Spark should be generated.

Is the inspection result normal?

INSPECTION END

INSPECTION END Replace spark plug(s) with standard type one(s). For spark plug type. Refer to InspectionInspection

Replace spark plug(s) with standard type one(s). For spark plug type. Refer to InspectionInspection .

.10.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to Inspection i.

i. Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

i.

i.Is the inspection result normal?

Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

Check pistons, piston rings, valves, valve seats and cylinder head gaskets.11.CHECK FUEL PRESSURE

- Install all removed parts.

- Release fuel pressure to zero.

- Install fuel pressure gauge and check fuel pressure. Refer to Work ProcedureWork Flow

.

.At idling: Approximately 500 kPa (5.1 kg/cm2, 72.5 psi)

Is the inspection result normal?

12.DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging. Replace “fuel filter and fuel pump assembly”. Refer to Exploded View

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View .

. Repair or replace.

Repair or replace.

Is the inspection result normal?

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View

Replace “fuel filter and fuel pump assembly”. Refer to Exploded View .

. Repair or replace.

Repair or replace.13.CHECK IGNITION TIMING

Check the following items. Follow the Work Procedure

Follow the Work Procedure .

.

For procedure, refer to IGNITION TIMING : Periodic Maintenance .

.

.

.For specification, refer to IGNITION TIMING : Service Data .

.

.

.Is the inspection result normal?

Follow the Work Procedure

Follow the Work Procedure .

.14.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect A/F sensor 1 harness connector.

- Disconnect ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

+ − Continuity A/F sensor 1 ECM Connector Terminal Connector Terminal F18 1 F51 56 Existed 2 60 - Check the continuity between A/F sensor 1 harness connector or ECM harness connector and ground.

+ − Continuity A/F sensor 1 Connector Terminal F18 1 Ground Not existed 2 + − Continuity ECM Connector Terminal F51 56 Ground Not existed 60 - Also check harness for short to power.

Is the inspection result normal?

Repair open circuit or short to ground or short to power in harness or connectors.

Repair open circuit or short to ground or short to power in harness or connectors.15.CHECK A/F SENSOR 1 HEATER

Check the A/F sensor 1 heater. Refer to Component Inspection .

. Replace A/F sensor 1. Refer to Exploded View

Replace A/F sensor 1. Refer to Exploded View .

.

.

.Is the inspection result normal?

Replace A/F sensor 1. Refer to Exploded View

Replace A/F sensor 1. Refer to Exploded View .

.16.CHECK MASS AIR FLOW SENSOR

Check the mass air flow sensor. Refer to Component Inspection .

. Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or ground. Refer to DTC Description

Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or ground. Refer to DTC Description .

.

.

.Is the inspection result normal?

Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or ground. Refer to DTC Description

Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or ground. Refer to DTC Description .

.17.CHECK SYMPTOM TABLE

Check items on the rough idle symptom in refer to Symptom Table .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.18.ERASE THE 1ST TRIP DTC

Some tests may cause a 1st trip DTC to be set.

Erase the 1st trip DTC from the ECM memory after performing the tests. Refer to M.U.T.-III SE FunctionCONSULT Function .

.

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)