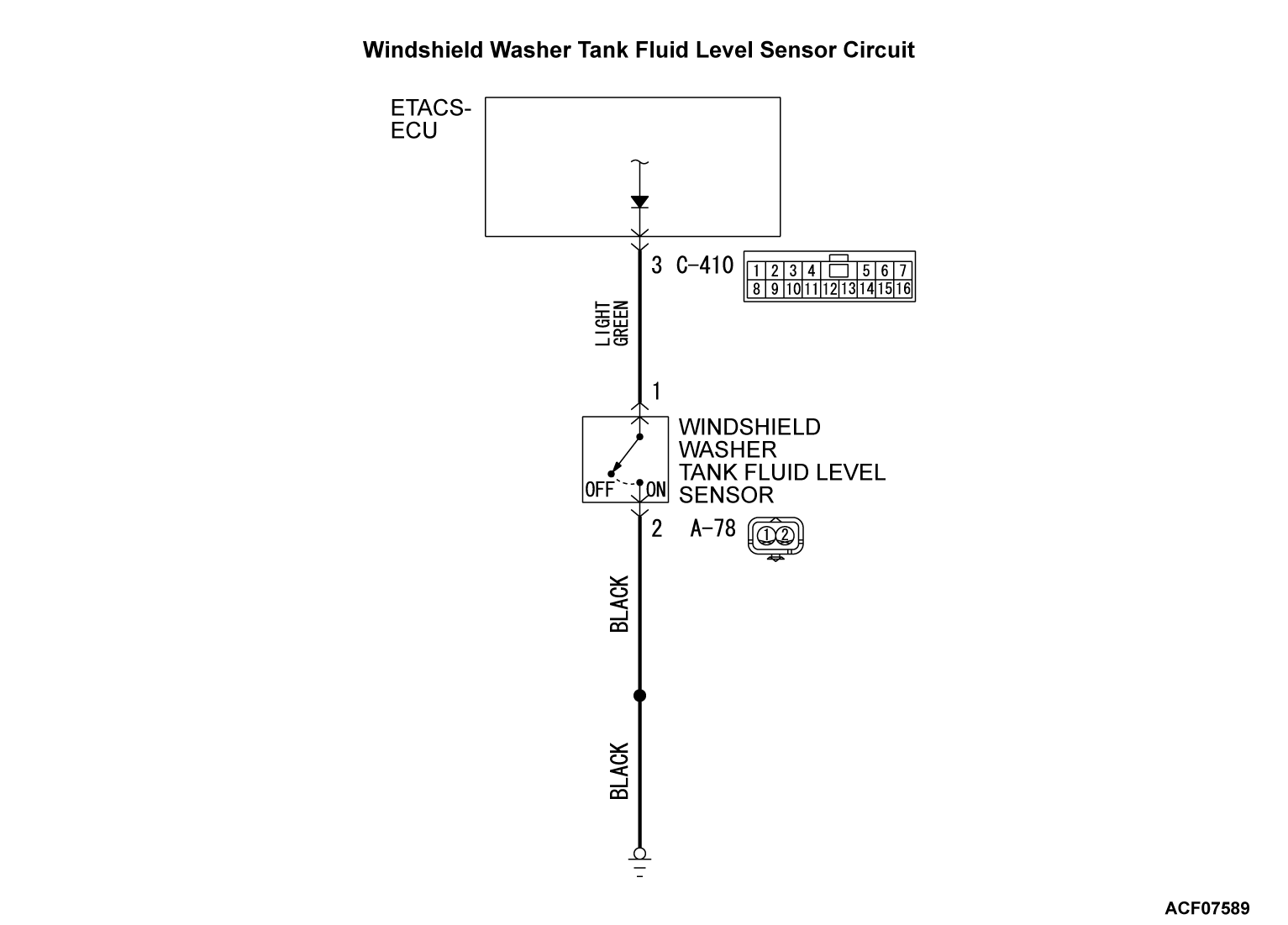

Inspection Procedure 15: ETACS-ECU does not receive any signal from the windshield washer tank fluid level sensor.

TECHNICAL DESCRIPTION (COMMENT)

If there is an error to the windshield washer tank fluid level sensor input signal, the windshield washer tank fluid level sensor signal is no longer output to the communication line.

TROUBLESHOOTING HINTS

- The windshield washer tank fluid level sensor may be defective

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

- The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

STEP 1. windshield washer tank fluid level sensor check

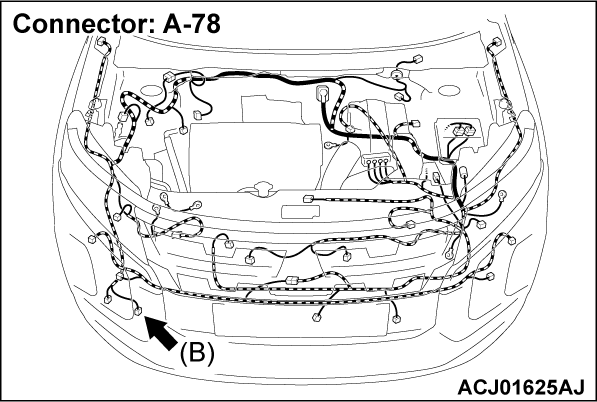

STEP 2. Check windshield washer tank fluid level sensor connector A-78 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is windshield washer tank fluid level sensor A-78 in good condition?

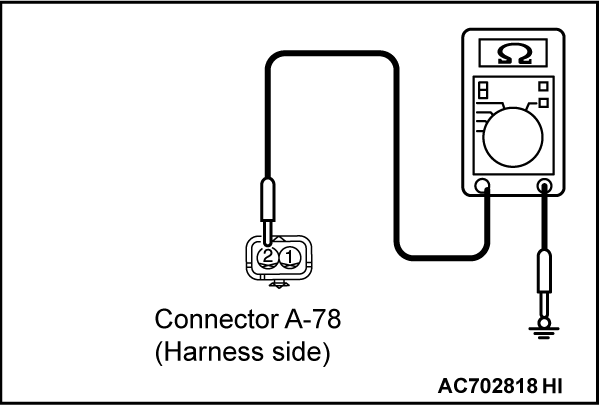

STEP 3. Check the ground circuit to the windshield washer tank fluid level sensor. Measure the resistance at windshield washer tank fluid level sensor connector A-78.

(1) Disconnect windshield washer tank fluid level sensor connector A-78 and measure the resistance available at the wiring harness side of the connector.

(2) Measure the resistance value between terminal 2 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 4. Check the wiring harness between windshield washer tank fluid level sensor connector A-78 (terminal 2) and ground.

Check the ground wires for open circuit. No action is necessary and testing is complete.

No action is necessary and testing is complete. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

Is the wiring harness between windshield washer tank fluid level sensor connector A-78 (terminal 2) and the ground in good condition?

No action is necessary and testing is complete.

No action is necessary and testing is complete. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

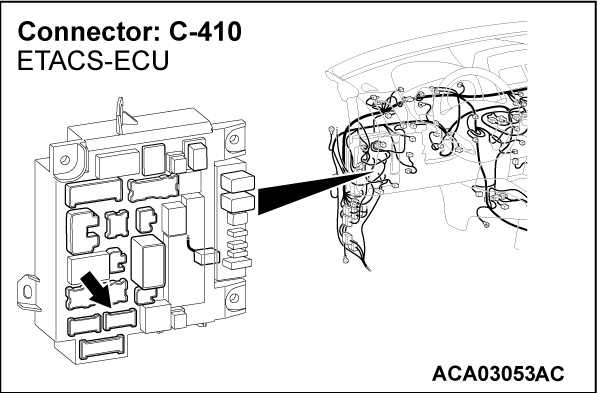

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.STEP 5. Check ETACS-ECU connector C-410 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is ETACS-ECU connector C-410 in good condition?

STEP 6. Check the wiring harness between windshield washer tank fluid level sensor connector A-78 (terminal 1) and ETACS-ECU connector C-410 (terminal 3).

Check the input lines for open circuit and short circuit. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

Is the wiring harness between windshield washer tank fluid level sensor connector A-78 (terminal 1) and ETACS-ECU connector C-410 (terminal 3) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. Check that the input signal of windshield washer tank fluid level sensor is normal.STEP 7. Using scan tool MB991958, check data list.

Check the input signals from the windshield washer tank fluid level sensor.

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction).

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction). Replace the ETACS-ECU.

Replace the ETACS-ECU.

- Drain the washer fluid.

|

OK: Normal condition is displayed.

Is the check result normal?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction).

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction). Replace the ETACS-ECU.

Replace the ETACS-ECU.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)