INSPECTION

WINDSHIELD WASHER MOTOR INSPECTION

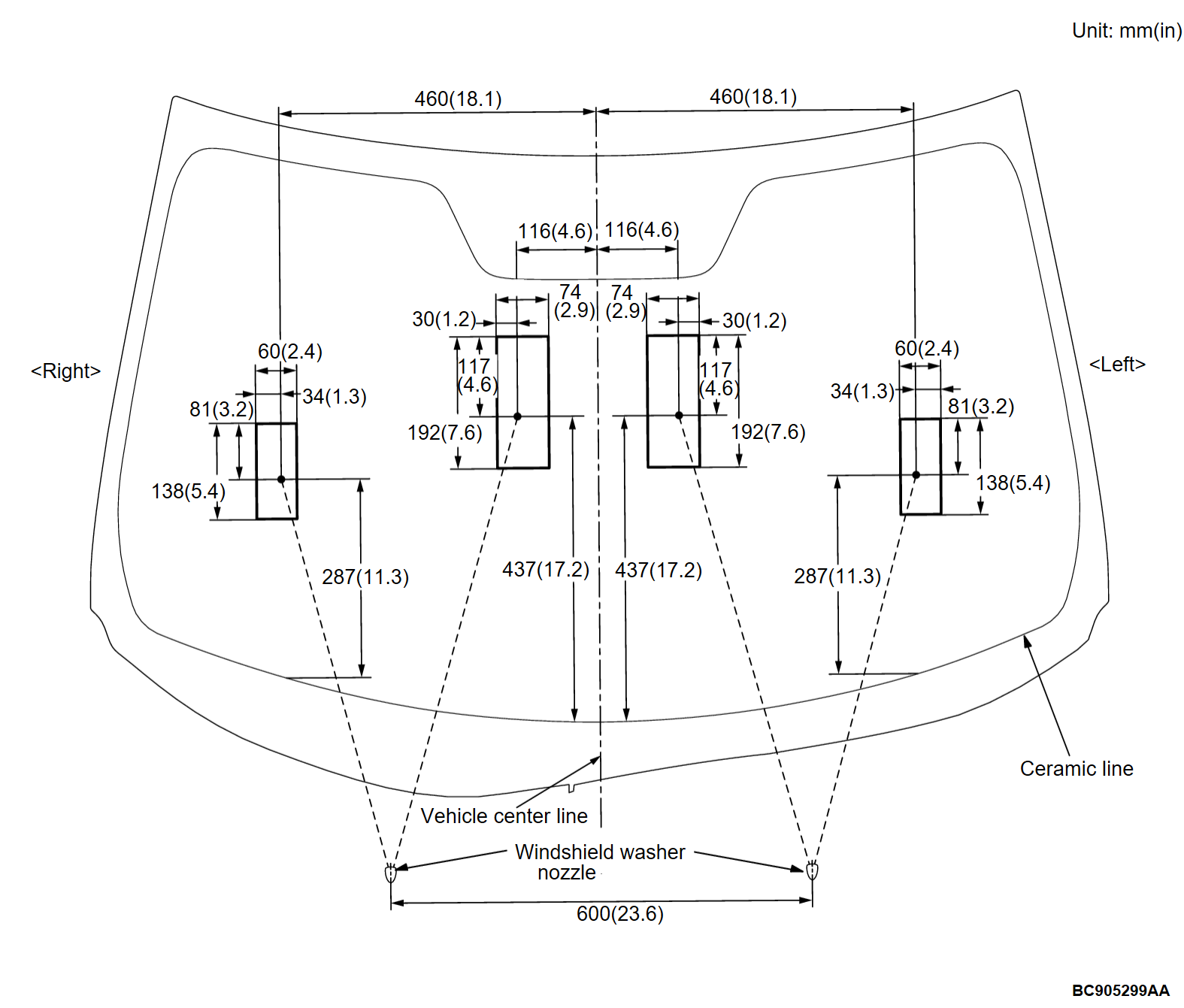

WINDSHIELD WASHER FLUID EJECTION CHECK

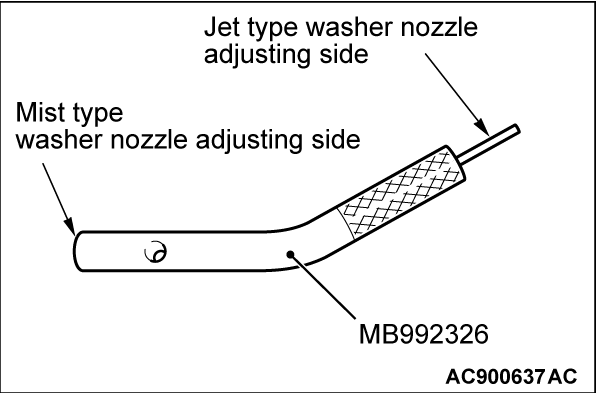

| note | Use special tool Adjustment tool, washer nozzle (MB992326) to adjust the splashing points of the nozzle. |

Adjustment of the jet type washer nozzle injection position

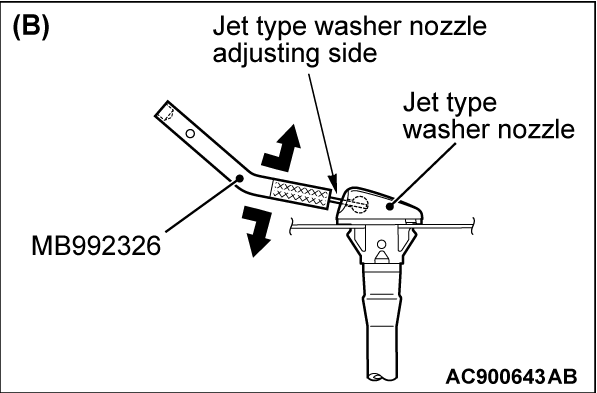

| caution | Adjust the splashing position within the specified adjustment range, otherwise the windshield cannot be washed properly. |

1. Use special tool Adjustment tool, washer nozzle (MB992326) to adjust the splashing points of the nozzle.

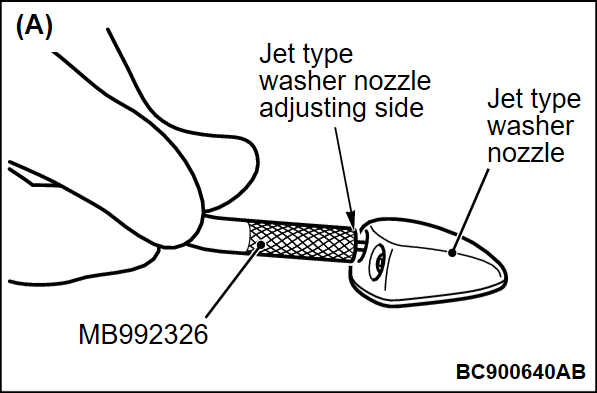

2. Insert the jet type washer nozzle adjusting side of the special tool Adjustment tool, washer nozzle (MB992326) into the injection part of the washer nozzle as shown in figure (A).

3. Move the special tool Adjustment tool, washer nozzle (MB992326) up and down to adjust the angle of the washer nozzle as shown in figure (B).

WINDSHIELD WASHER SWITCH CHECK

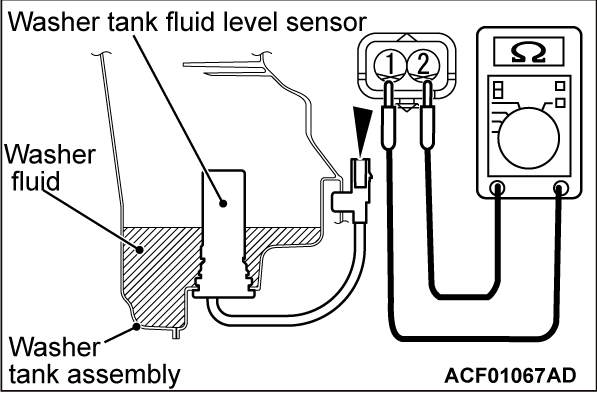

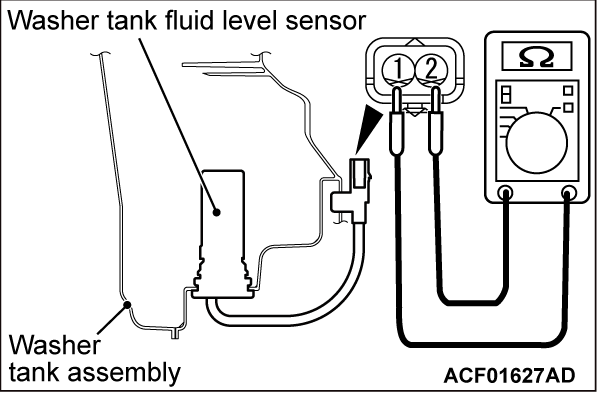

WINDSHIELD WASHER TANK FLUID LEVEL SENSOR INSPECTION

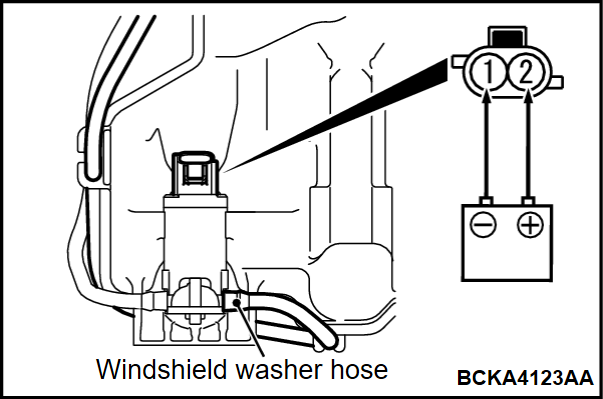

Washer fluid is filled

1. Check the windshield washer tank fluid level sensor without removing the windshield washer tank assembly.

2. Connect the connector terminals as shown. There should be no continuity between them.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)