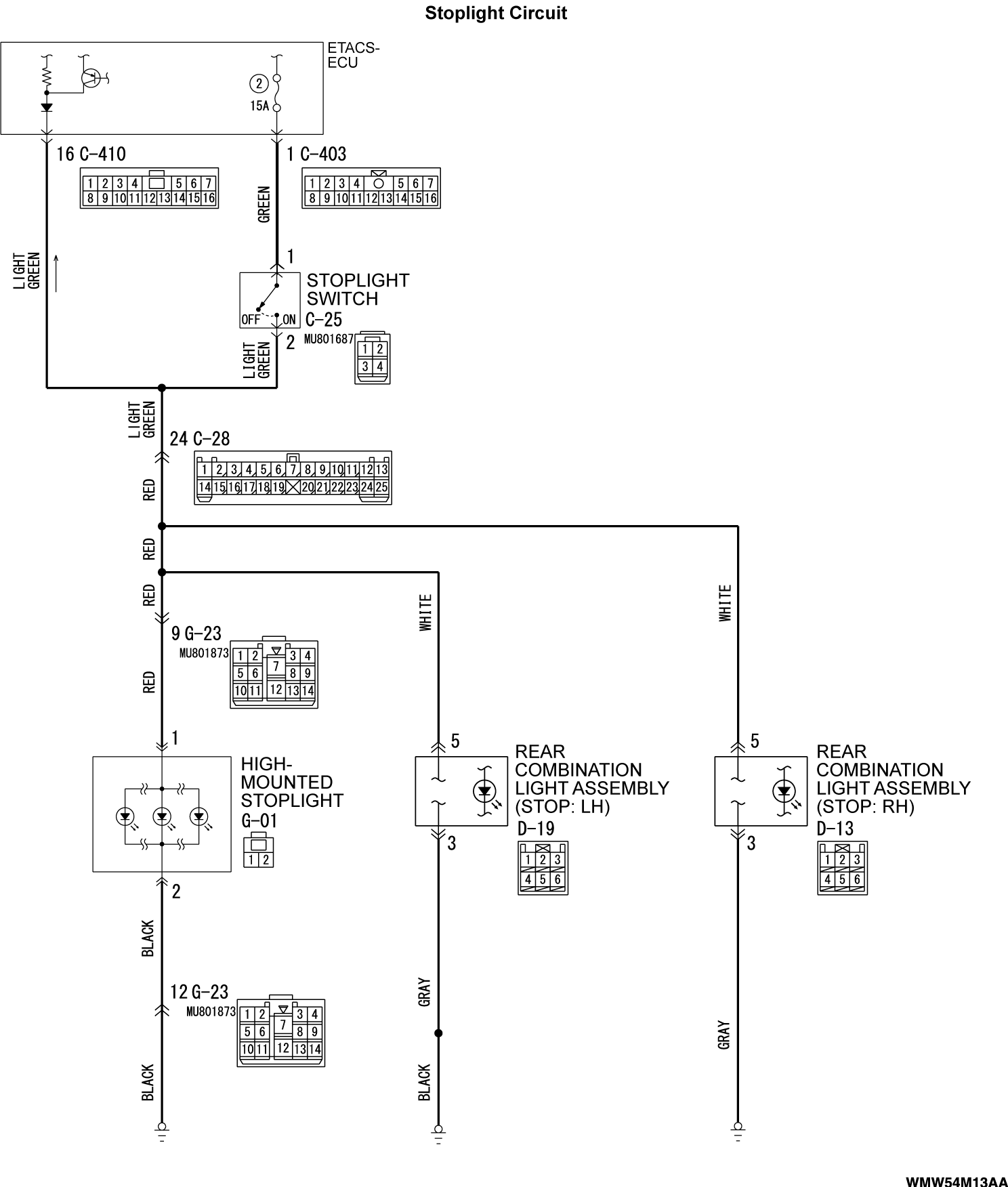

Inspection Procedure 3: Stoplight does not illuminate or go out normally. <Vehicles without stop light relay>

COMMENTS ON TROUBLE SYMPTOM

If the stoplights do not illuminate or go out normally, the stoplight relay power supply, ground circuit system, stoplight switch may be defective.

PROBABLE CAUSES

- Malfunction of stoplight switch

- Malfunction of stoplight

- Damaged harness wires and connectors

DIAGNOSIS

Required Special Tools:

- MB992006: Extra fine probe

- MB991223: Harness set

STEP 1. Using scan tool MB991958, check data list

Check the ETACS-ECU system data list.

- The brake pedal is depressed.

|

Is the check result normal?

STEP 2. Check the stoplight switch.

Check the stoplight switch. Refer to GROUP 35A - Brake Pedal  .

. Replace the stoplight switch.

Replace the stoplight switch.

.

.Is the stoplight switch in good condition?

Replace the stoplight switch.

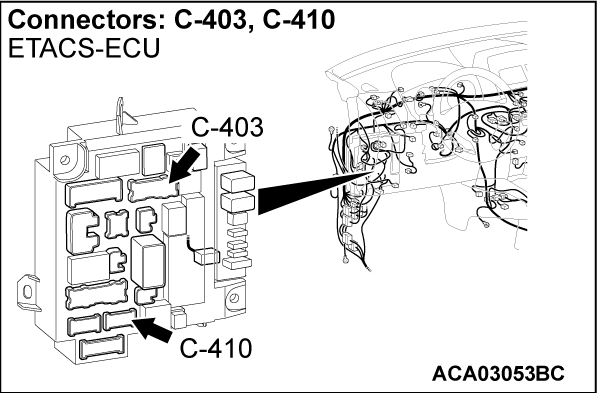

Replace the stoplight switch.STEP 3. Check ETACS-ECU connector C-403 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

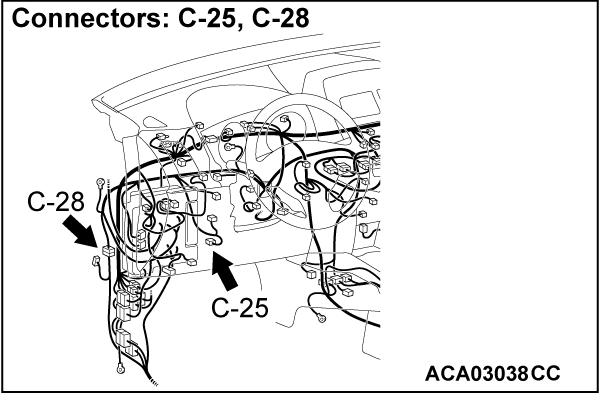

STEP 4. Check the wiring harness between stoplight switch connector C-25 (terminal 1) and ETACS-ECU connector C-403 (terminal 1).

- Check the power supply line (battery supply) for open circuit and short circuit.

Is the wiring harness between stoplight switch connector C-25 (terminal 1) and ETACS-ECU connector C-403 (terminal 1) in good condition?

Repair the wiring harness.

Repair the wiring harness.STEP 5. Check ETACS-ECU connectors C-410 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

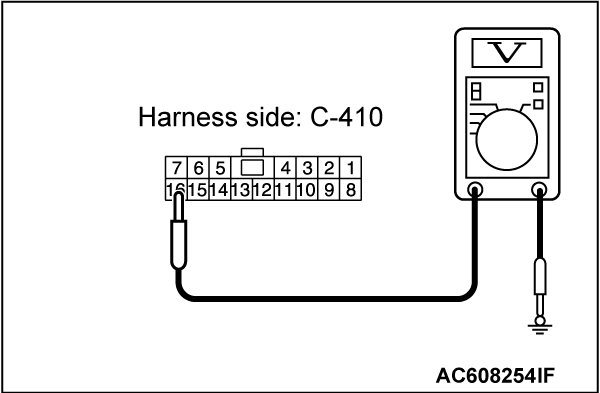

STEP 6. Check the battery power supply circuit to the ETACS-ECU. Measure the voltage at ETACS-ECU connector C-410.

(1) Disconnect connector measure the voltage available at the wiring harness side of the connector.

(2) Disconnecting the ETACS-ECU connector C-410.

(3) Stoplight switch: ON

(4) Measure the voltage between ETACS-ECU connector C-410 (terminal 16) and the body ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts (battery positive voltage)?

STEP 7. Check the wiring harness between ETACS-ECU connector C-410 (terminal 16) and stoplight switch connector C-25 (terminal 2).

- Check the signal line for short circuit.

Is the wiring harness between ETACS-ECU connector C-410 (terminal 16) and stoplight switch connector C-25 (terminal 2) in good condition?

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

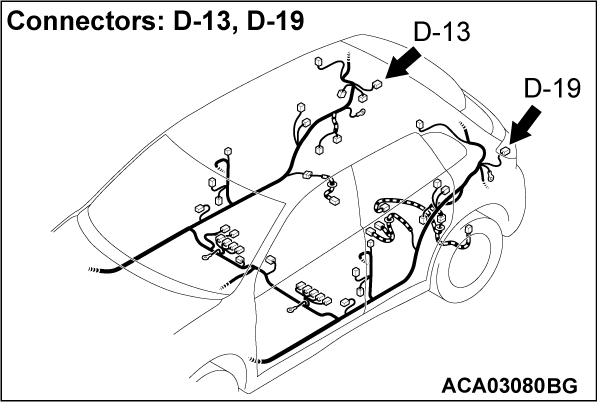

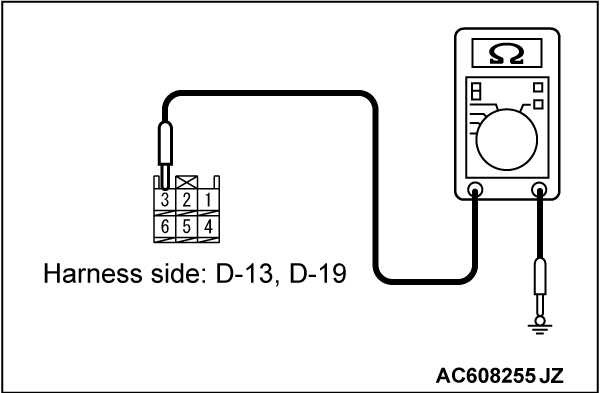

Repair the wiring harness.STEP 8. Check the ground circuit to the rear combination light (stop: LH) or rear combination light (stop: RH). Measure the resistance at rear combination light (stop: LH) connector D-19 or rear combination light (stop: RH) connector D-13.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the resistance between the rear combination light connector and ground.Resistance between rear combination light (stop: LH) connector D-19 (terminal 3) or rear combination light (stop: RH) connector D-13 (terminal 3) and ground

OK: The measured value should be continuity exists (2 ohms or less).

Is the measured resistance 2 ohms or less?

STEP 9. Check the wiring harness between rear combination light (stop: LH) connector D-19 (terminal 3) or rear combination light (stop: RH) connector D-13 (terminal 3) and ground.

- Check the ground wires for open circuit.

Is the wiring harness between rear combination light (stop: LH) connector D-19 (terminal 3) or rear combination light (stop: RH) connector D-13 (terminal 3) and ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 10. Check the wiring harness between stoplight switch connector C-25 (terminal 2) and rear combination light (stop: LH) connector D-19 (terminal 5) or rear combination light (stop: RH) connector D-13 (terminal 5).

Check the communication line for open or short circuit.

Repair the wiring harness.

Repair the wiring harness.

| note | Prior to the wiring harness inspection, check junction connector C-28, and repair if necessary. |

Is the wiring harness between stoplight switch connector C-25 (terminal 2) and rear combination light (stop: LH) connector D-19 (terminal 5) or rear combination light (stop: RH) connector D-13 (terminal 5 in good condition?

Repair the wiring harness.

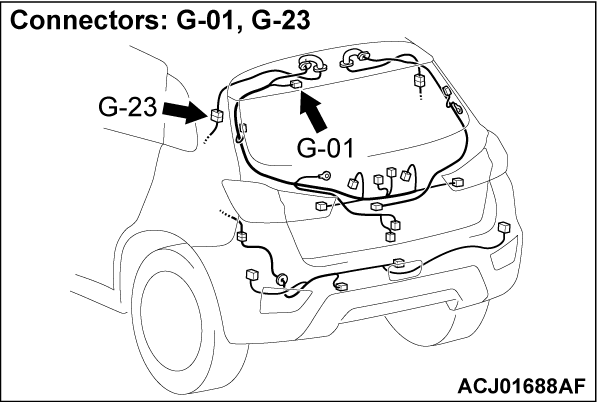

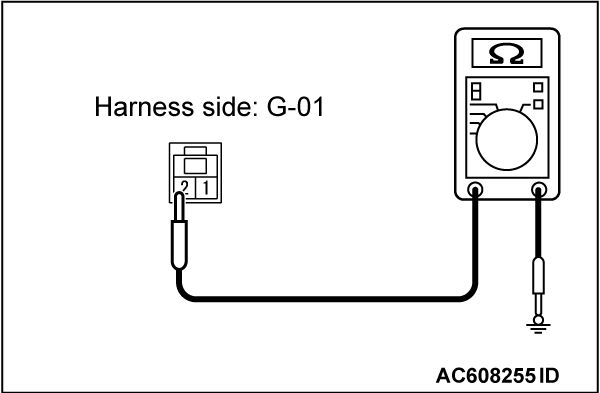

Repair the wiring harness.STEP 11. Check the ground circuit to the high mounted stoplight. Measure the resistance at high mounted stoplight connector G-01.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the resistance between the high mounted stoplight connector and ground.

- Resistance between high mounted stoplight connector G-01 (terminal 2) and ground

OK: The measured value should be continuity exists (2 ohms or less).

Is the measured resistance 2 ohms or less?

STEP 12. Check the wiring harness between high mounted stoplight connector G-01 (terminal 2) and ground.

- Check the ground wires for open circuit.

Is the wiring harness between high mounted stoplight connector G-01 (terminal 2) and ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 13. Check the wiring harness between stoplight switch connector C-25 (terminal 2) and high mounted stoplight connector G-01 (terminal 1).

Check the communication line for open or short circuit.

Repair the wiring harness.

Repair the wiring harness.

| note | Prior to the wiring harness inspection, check junction connector C-28, G-23, and repair if necessary. |

Is the wiring harness between stoplight switch connector C-25 (terminal 2) and high mounted stoplight connector G-01 (terminal 1) in good condition?

Repair the wiring harness.

Repair the wiring harness.STEP 14. Retest the system

Check that the stoplight illuminates normally. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the stoplight switch.

Replace the stoplight switch.

Does the stoplight relay work normally?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the stoplight switch.

Replace the stoplight switch.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)