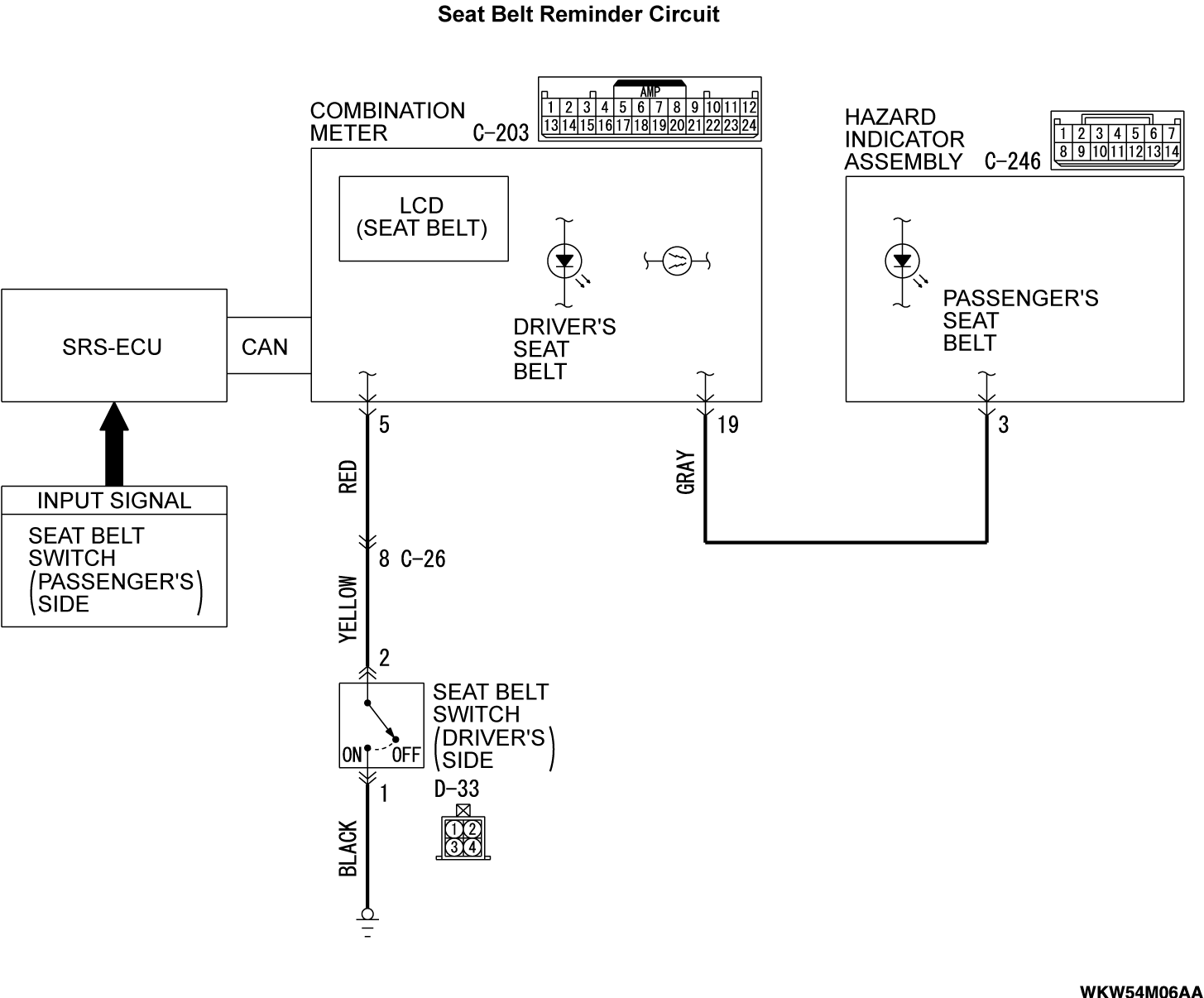

Inspection Procedure 8: Seat belt reminder function does not work normally.

| caution | Whenever the ECU is replaced, ensure that the input and output signal circuits are normal. |

TECHNICAL DESCRIPTION (COMMENT)

If the seat belt reminder function does not work normally, the seat belt switch input circuit, the combination meter or hazard indicator assembly may be defective.

TROUBLESHOOTING HINTS

- The seat belt switch (driver’s side) may be defective.

- The seat belt switch (passenger’s side) may be defective.

- The combination meter may be defective.

- The hazard indicator assembly may be defective.

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the CAN bus line found to be normal?

STEP 2. Using scan tool MB991958, read for SRS diagnostic trouble code.

Check the DTC is set in the SRS.

Is the DTC set?

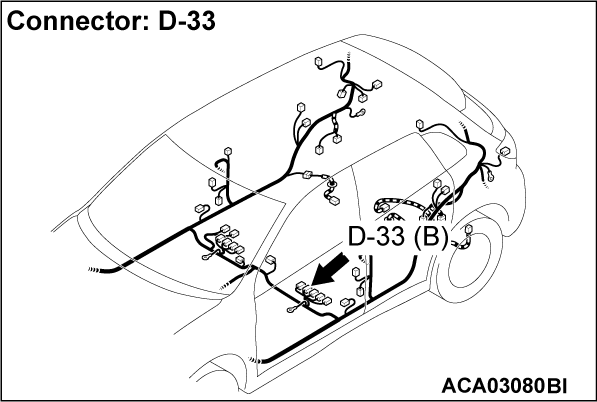

STEP 3. Check seat belt switch (driver’s side) connector D-33 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is seat belt switch (driver’s side) connector D-33 in good condition?

Repair the defective connector.

Repair the defective connector.STEP 4. Check the seat belt switch.

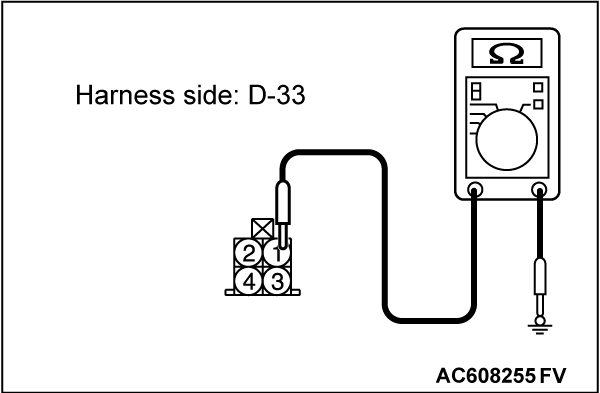

STEP 5. Check the ground circuit to the seat belt switch (driver’s side). Test at seat belt switch (driver’s side) connector D-33.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Measure the resistance value between terminal 1 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 6. Check the wiring harness between seat belt switch (driver’s side) connector D-33 (terminal 1) and ground.

Check the ground wire for open circuit. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

Repair the wiring harness.

Is the wiring harness between seat belt switch (driver’s side) connector D-33 (terminal 1) and ground in good condition?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

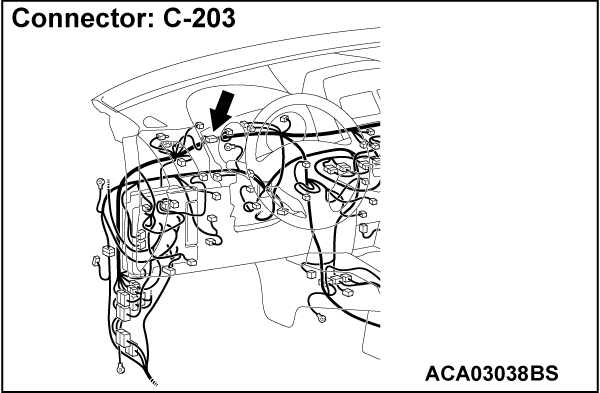

Repair the wiring harness.STEP 7. Check combination meter connector C-203 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

STEP 8. Check the wiring harness between combination meter connector C-203 (terminal 5) and seat belt switch <driver’s side> connector D-33 (terminal 2).

- Check the input line for open and short circuit.

Is the wiring harness between combination meter connector C-203 (terminal 5) and seat belt switch <driver’s side> connector D-33 (terminal 2) in good condition?

Repair the wiring harness.

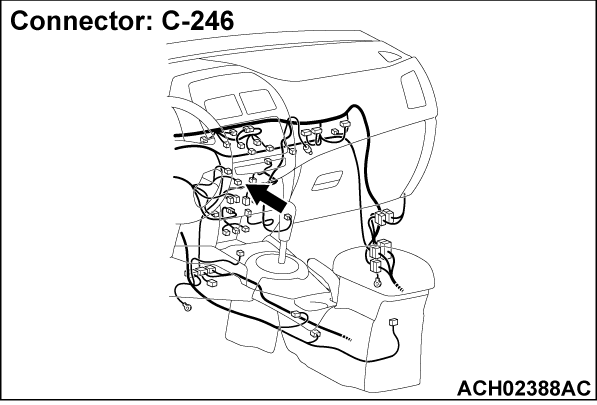

Repair the wiring harness.STEP 9. Check hazard indicator assembly connector C-246 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is hazard indicator assembly connector C-246 in good condition?

Repair the defective connector.

Repair the defective connector.STEP 10. Check the wiring harness between combination meter connector C-203 (terminal 19) and hazard indicator assembly connector C-246 (terminal 3).

- Check the input line for open and short circuit.

Is the wiring harness between combination meter connector C-203 (terminal 19) and hazard indicator assembly connector C-246 (terminal 3) in good condition?

Repair the wiring harness.

Repair the wiring harness.STEP 11. Retest the system.

The seat belt reminder function should work normally. <The seat belt reminder function works normally.> : The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

<The seat belt reminder function works normally.> : The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). <Tone alarm sounds do not sound.> : Replace the combination meter.

<Tone alarm sounds do not sound.> : Replace the combination meter. <The indicator (driver’s side) does not illuminate.> : Replace the combination meter.

<The indicator (driver’s side) does not illuminate.> : Replace the combination meter. <The indicator (passenger’s side) does not illuminate.> : Replace the hazard indicator assembly.

<The indicator (passenger’s side) does not illuminate.> : Replace the hazard indicator assembly.

Is the check result normal?

<The seat belt reminder function works normally.> : The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

<The seat belt reminder function works normally.> : The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). <Tone alarm sounds do not sound.> : Replace the combination meter.

<Tone alarm sounds do not sound.> : Replace the combination meter. <The indicator (driver’s side) does not illuminate.> : Replace the combination meter.

<The indicator (driver’s side) does not illuminate.> : Replace the combination meter. <The indicator (passenger’s side) does not illuminate.> : Replace the hazard indicator assembly.

<The indicator (passenger’s side) does not illuminate.> : Replace the hazard indicator assembly.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)