DTC B2101: IG SW start POS.circuit low

DTC B2102: IG SW start POS.circuit high

DTC B2102: IG SW start POS.circuit high

| caution |

|

DTC SET CONDITION

If the actual the engine switch status is different from the power supply mode of the engine switch status information received from ETACS-ECU via CAN, KOS-ECU sets the diagnostic trouble code No. B2101 or B2102.

TECHNICAL DESCRIPTION (COMMENT)

If the difference in the power supply mode of the engine switch level shown below occurs consecutively 10 times with the power supply mode of the engine switch being the ON position or START position, when the CAN message (power supply mode of engine switch position information) from ETACS-ECU, KOS-ECU determines that there is a problem.

B2101

- Status of the power supply mode of the engine switch: ON position

- The power supply mode of the engine switch position information: OFF

B2102

- Status of the power supply mode of the engine switch: OFF position

- The power supply mode of the engine switch position information: ON

TROUBLESHOOTING HINTS

- Malfunction of CAN bus line

- Malfunction of the KOS-ECU

- Malfunction of the engine switch

- Damaged wiring harness and connectors

- Malfunction of ETACS-ECU

DIAGNOSIS

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool (MB991958), always turn the power supply mode of the engine switch to the OFF position before connecting or disconnecting scan tool (MB991958). |

(2) Turn the power supply mode of the engine switch to ON.

(3) Diagnose the CAN bus line.

(4) Turn the power supply mode of the engine switch to OFF.

Is the CAN bus line found to be normal?

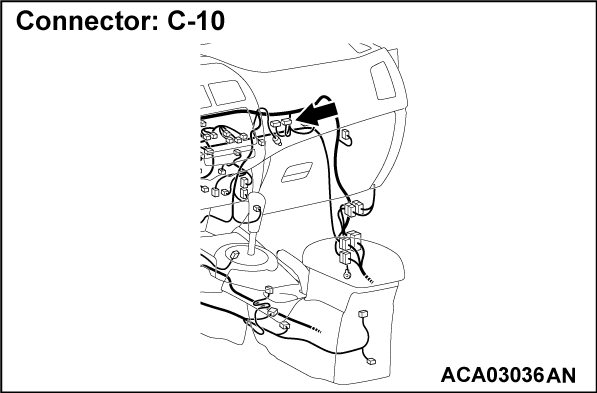

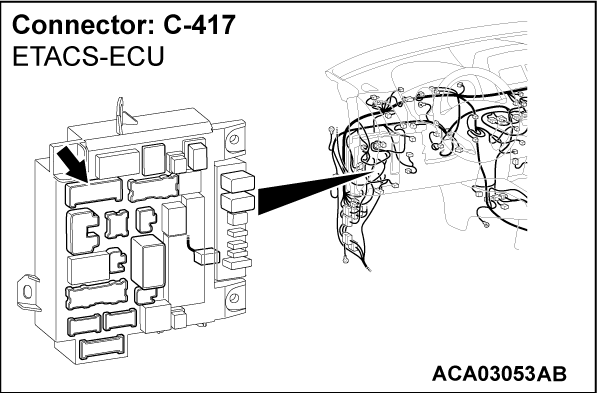

STEP 2. Check ETACS-ECU connector C-417 and KOS-ECU connector C-10 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is ETACS-ECU connector C-417 and KOS-ECU connector C-10 in good condition?

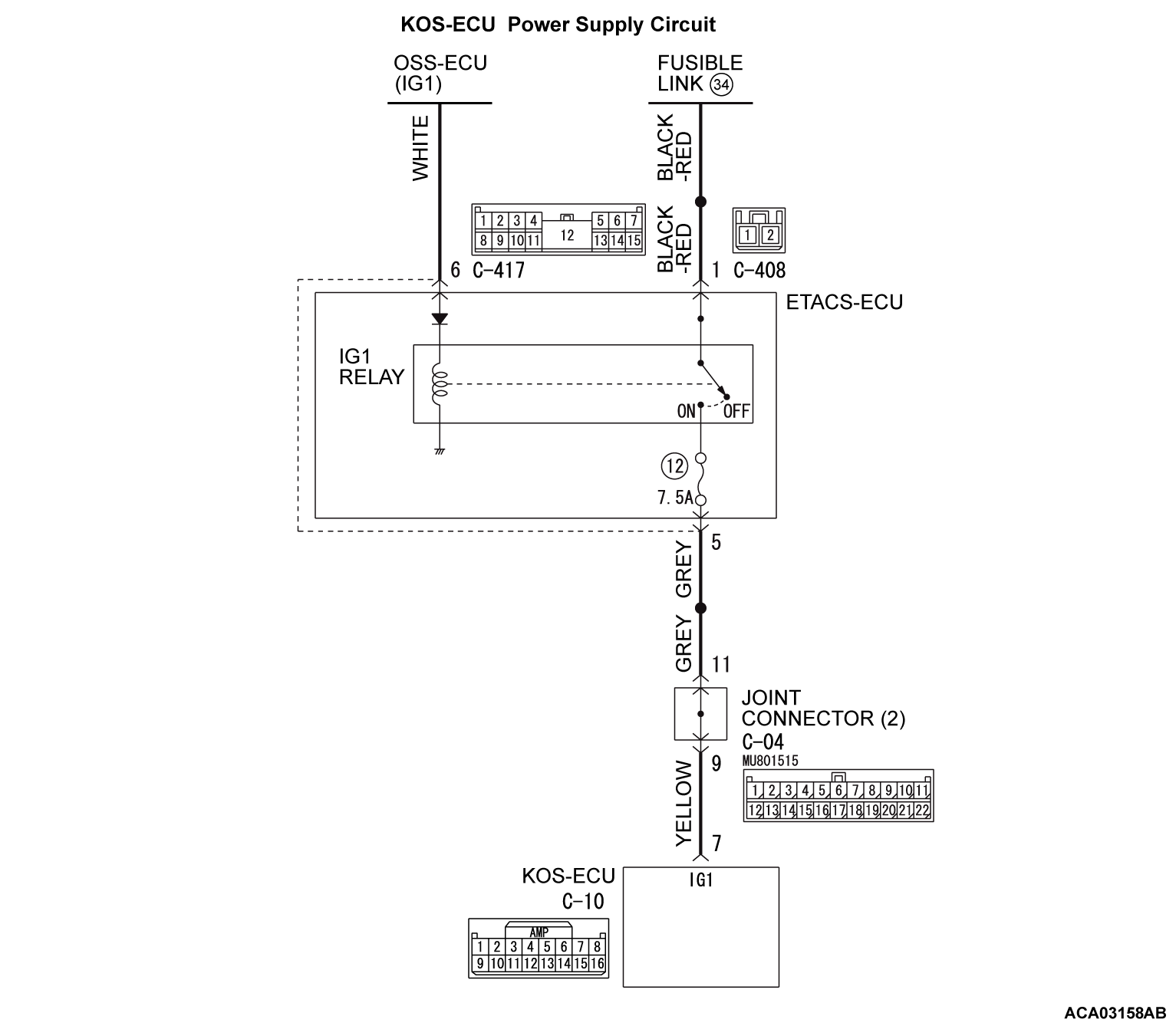

STEP 3. Check the wiring harness between KOS-ECU connector C-10 (terminal No.7) and ETACS-ECU connector C-417 (terminal No.5).

- Check the power supply line for open circuit.

Is the wiring harness between KOS-ECU connector C-10 (terminal No. 7) and ETACS-ECU connector C-417 (terminal No. 5) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 4. Using scan tool MB991958, check data list.

Use the ETACS-ECU data list to check the signals related to the ignition voltage.

Turn the power supply mode of the engine switch from OFF to ON.

|

Does scan tool MB991958 display the item "IG voltage" as normal condition?

STEP 5. Recheck for diagnostic trouble code.

Check again if the DTC is set to the KOS-ECU.

(1) Erase the DTC.

(2) Turn the power supply mode of the engine switch from OFF to ON.

(3) Check if DTC is set.

(4) Turn the power supply mode of the engine switch to OFF.

Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)