Inspection Procedure 1: Scan tool cannot communicate with electric power steering system <ECU power supply circuit system check>.

COMMENTS ON TROUBLE SYMPTOM

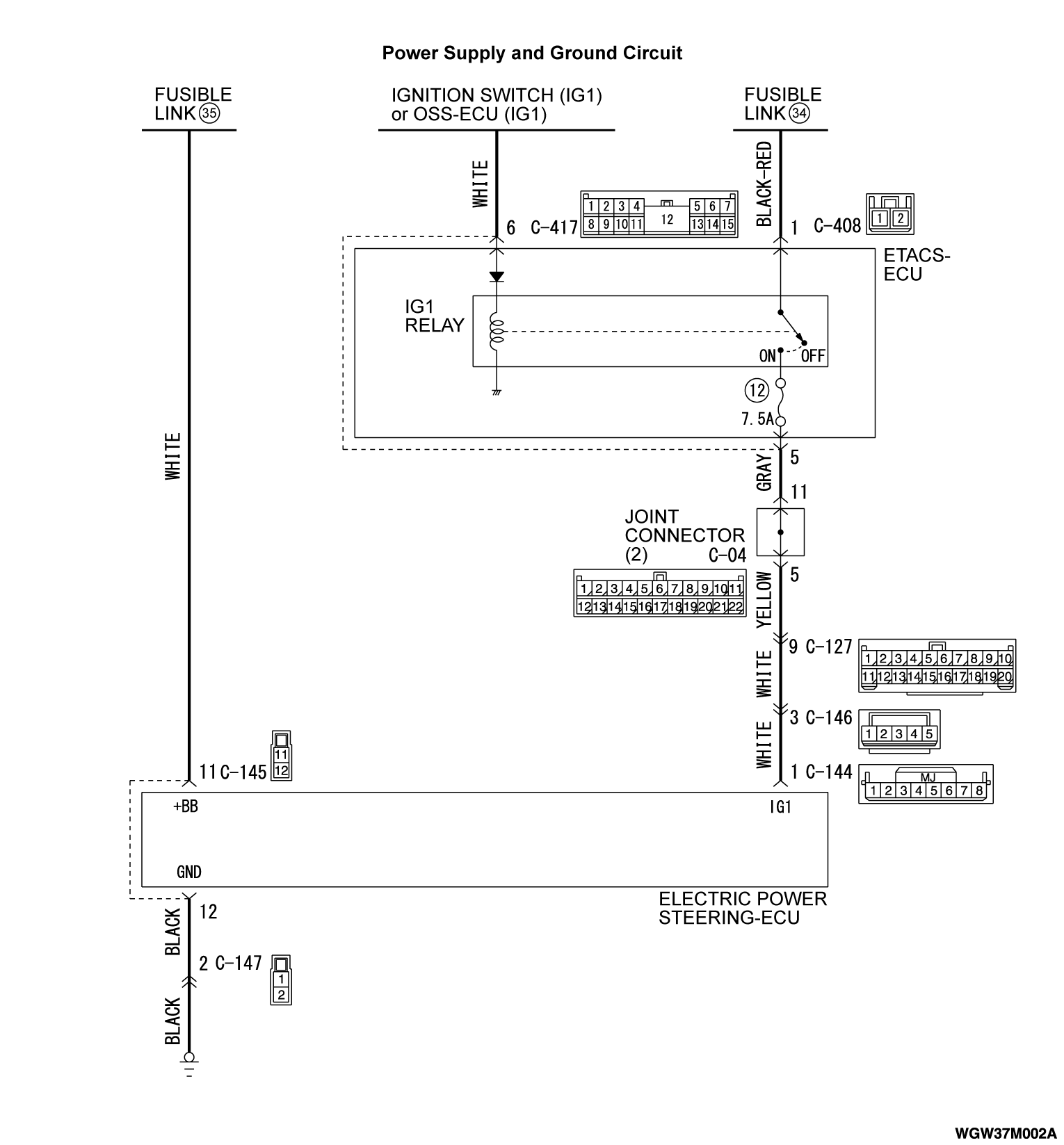

If the scan tool MB991958 cannot communicate with the electric power steering system, the CAN bus lines may be defective. If the electric power steering system does not operate, the electric power steering-ECU or its power supply may be defective.

PROBABLE CAUSES

- Malfunction of CAN bus line

- Defective harness wire(s) or connector(s)

- Short or open circuit between the electric power steering-ECU and the ETACS-ECU, the fusible link or loose connector contact

- Open circuit between the body ground and the electric power steering-ECU or loose connector contact

- Malfunction of the ETACS-ECU

- Malfunction of the electric power steering-ECU

DIAGNOSIS

STEP 1. Using scan tool MB991958, diagnose the CAN bus lines.

Use scan tool to diagnose the CAN bus lines.

Is the check result normal?

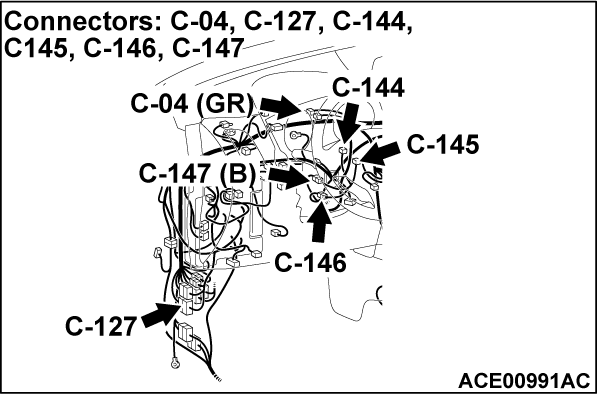

STEP 2. Check the following connector.

Check the connectors below for improper engagement, terminal damage or terminal drawn in the connector case. Repair the defective connector(s) or terminal(s).

Repair the defective connector(s) or terminal(s).

- C-144 and C-145 electric power steering-ECU connector

- C-408 and C-417 ETACS-ECU connector

- C-127, C-146 and C-147 intermediate connector

- C-04 joint connector

- No.34 and 35 fusible link

- Body ground point

Is the connectors and terminals in good condition?

Repair the defective connector(s) or terminal(s).

Repair the defective connector(s) or terminal(s).STEP 3. Wiring harness check

(1) Check the wiring harness between the C-145 electric power steering-ECU connector terminal No.11 and the fusible link No.35 for damage or other problem.

(2) Check the wiring harness between the C-144 electric power steering-ECU connector terminal No.1, the C-146 intermediate connector terminal No.3, the C-127 intermediate connector terminal No.9, the C-04 joint connector terminal No.5, the C-04 joint connector terminal No.11 and the C-417 ETACS-ECU connector terminal No.5 for damage or other problem.

(3) Check the wiring harness between the C-408 ETACS-ECU connector terminal No.1 and the fusible link No.34 for damage or other problem.

(4) Check the wiring harness between the C-145 electric power steering-ECU connector terminal No.12, the C-147 intermediate connector terminal No.2 and the body ground point for damage or other problem.

Is the wiring harness in good condition?

Repair the defective wiring harness.

Repair the defective wiring harness.STEP 4. Voltage measurement at the ETACS-ECU connector

(1) Measure the ETACS-ECU voltage without disconnecting the connector (by backprobing).

(2) Turn the ignition switch from the "LOCK" (OFF) position to the "ON" position.

(3) Measure the voltage between the C-408 ETACS-ECU connector terminal No.1 and the C-417 ETACS-ECU connector terminal No.5.

OK: Approximately system voltage

Is the check result normal?

STEP 5. Voltage measurement at the electric power steering-ECU connector

(1) Measure the electric power steering-ECU voltage without disconnecting the connector (by backprobing).

(2) Turn the ignition switch from the "LOCK" (OFF) position to the "ON" position.

(3) Measure the voltage between the C-144 electric power steering-ECU connector terminal No.1 and the C-145 electric power steering-ECU connector terminal No.12.

OK: Approximately system voltage

(4) Measure the voltage between the C-145 electric power steering-ECU connector terminals No.11 and No.12.

OK: Approximately system voltage

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)