FRONT WHEEL ALIGNMENT CHECK AND ADJUSTMENT

| caution | After the installation, perform a calibration for the ASC-ECU to learn the steering wheel sensor neutral point. (Refer to GROUP 35C - On-vehicle Service - Steering Wheel Sensor Calibration  ). ). |

Measure wheel alignment with alignment equipment on a level surface. The front suspension, steering system, wheels, and tires should be serviced to normal condition before measuring wheel alignment.

TOTAL TOE-IN

Standard value: 1 ± 2 mm (0.04 ± 0.08 inch)

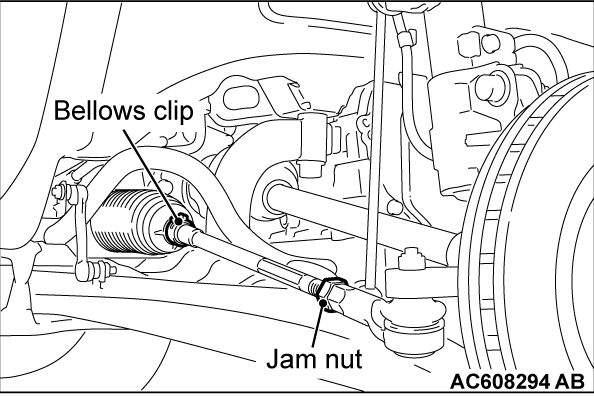

1. Adjust the total toe-in by undoing the bellows clip and jam nut, and turning the left and right tie rod turnbuckles by the same amount (in opposite directions).

| note | The toe will move out as the left turnbuckle is turned toward the front of the vehicle and the right turnbuckle is turned toward the rear of the vehicle. |

2. Install the bellows clip and tighten the jam nut to the specified torque.

Tightening torque: 52 ± 2 N·m (38 ± 1 ft-lb)

3. Confirm that the total toe-in is at the standard value.

CAMBER, CASTER AND KINGPIN INCLINATION

Required Special Tool:

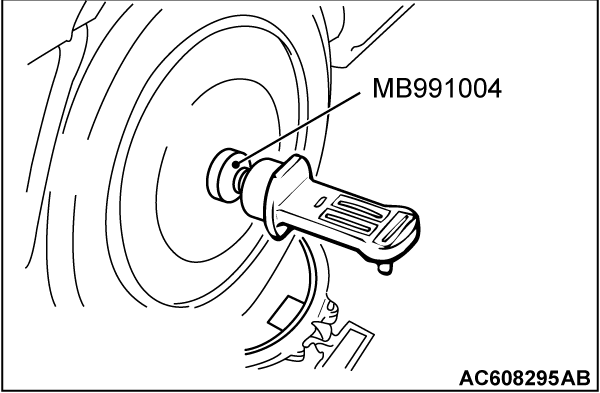

- MB991004: Wheel Alignment Gauge Attachment<Vehicles with aluminum wheels>

Standard value:

- Camber: 0°20' ± 0°30' (Difference between right and left wheels must be 0°30' or less.)

- Caster: 2°45' ± 0°30' (Difference between right and left wheels must be 0°30' or less.)

- Kingpin inclination: 12°45' ± 1°30'

| note | Camber and caster are preset at the factory and cannot be adjusted. |

| caution | Never subject the wheel bearings to the vehicle load when the drive shaft nuts are loosened. |

| note | For vehicles with aluminum type wheels, attach the camber/caster/kingpin gauge to the driveshaft by using the special tool MB991004. Tighten the special tool MB991004 to the same torque 144 - 176 N·m (107 - 129 ft-lb) as the driveshaft nut. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)