DTC P0703: Malfunction of Stoplight Switch

DIAGNOSTIC FUNCTION

TCM detects malfunction using the stoplight switch signal sent from the ETACS-ECU.

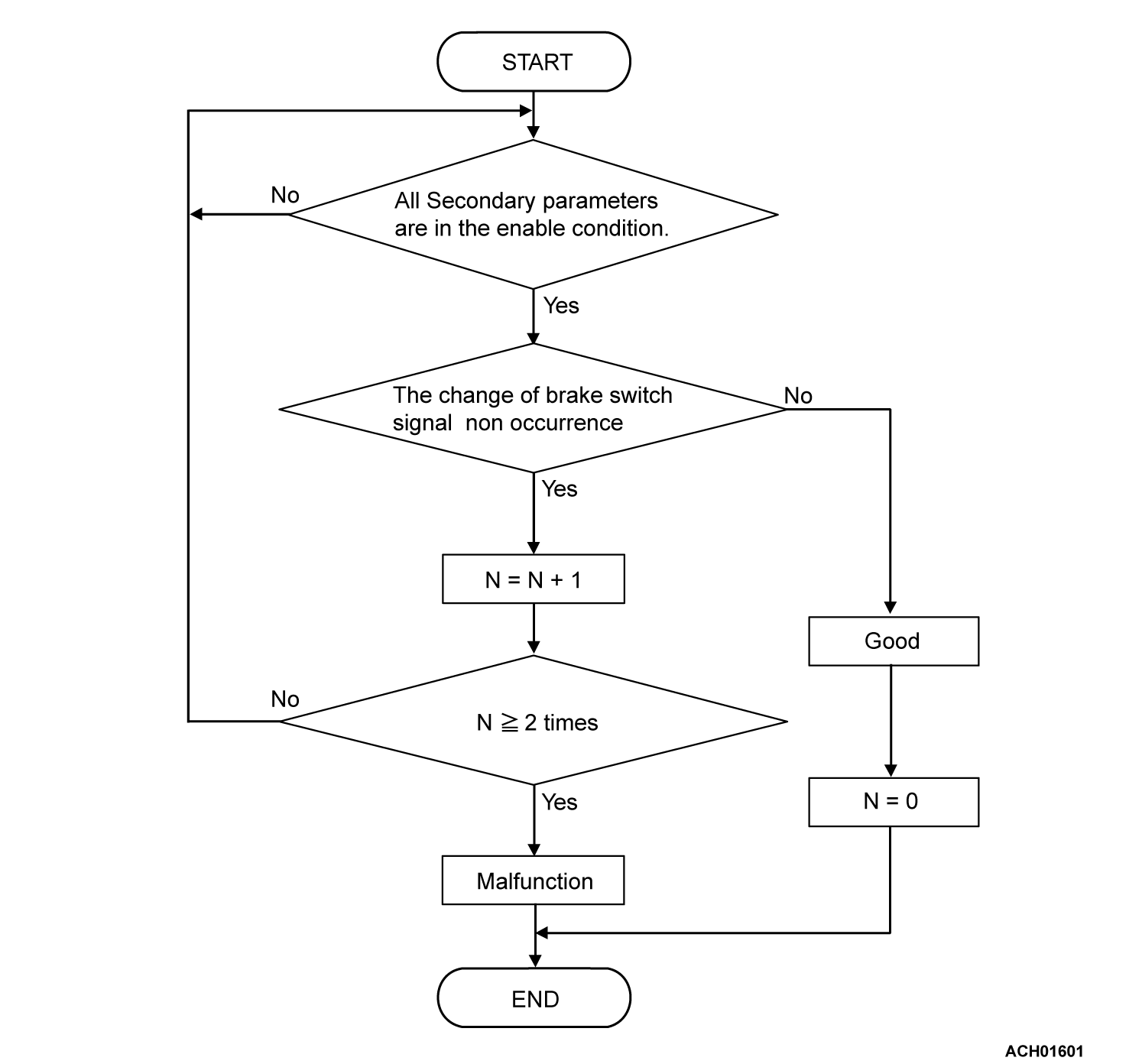

DESCRIPTIONS OF MONITOR METHODS

Drive the vehicle at 30 km/h (19 mph) or more for 10 seconds, and then turn the ignition switch to the "LOCK" (OFF) position. In this sequential operation, no variation has been found in the stoplight switch input signal in two consecutive times.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Vehicle speed: 30 km/h (19 mph) or more.

- Voltage of battery: 10 volts or more.

Judgment Criteria

- The change of stoplight switch signal during driving cycle: no occurrence (10 seconds × 2 times).

OBD-II DRIVE CYCLE PATTERN

Drive the vehicle for 10 seconds or more at 30 km/h (19 mph) or higher (2 drive cycle)

PROBABLE CAUSES

- Malfunction of CAN bus line

- Malfunction of the stoplight switch

- Damaged wiring harness and connectors

- Malfunction of TCM

- Malfunction of ETACS-ECU

DIAGNOSIS

STEP 1. M.U.T.-III CAN bus diagnostics

Use scan tool to perform the CAN bus diagnosis.

Is the check result normal?

STEP 2. M.U.T.-III data list

Item 59: Brake switch

OK: The service data changes in response to the brake operation.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)