DTC P0400: Exhaust Gas Recirculation System

TECHNICAL DESCRIPTION

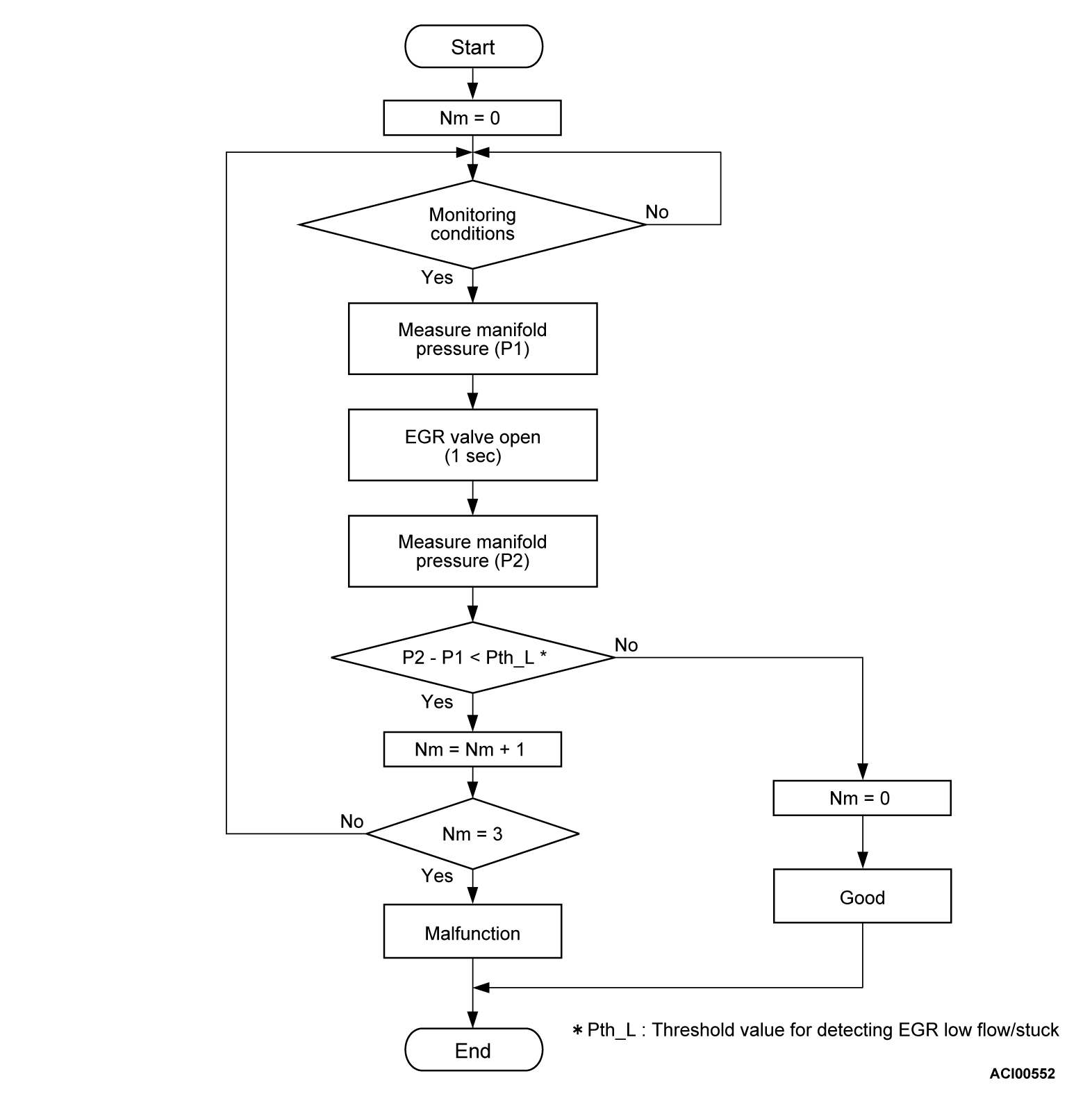

- When the EGR valve (stepper motor) is actuated from the fully closed position toward the open position while the engine is running, EGR gas flows.

- The ECM checks how the EGR gas flow signal changes.

DESCRIPTIONS OF MONITOR METHODS

- Small manifold pressure change during exhaust gas recirculation (EGR) operation from closed to open.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Exhaust gas recirculation (EGR) stepper motor monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Accelerator pedal position sensor

- Manifold absolute pressure sensor

Check Conditions

- At least 20 seconds have passed since the last monitor was complete.

- Engine coolant temperature is more than 76°C (169°F).

- Engine speed is between 1,188 and 2,500 r/min.

- Intake air temperature is more than -10°C (14°F).

- Barometric pressure is more than 76 kPa (22.4 in.Hg).

- Fuel is being shut off.

- Vehicle speed is more than 30 km/h (19 mph).

- At least 90 seconds have passed since manifold absolute pressure sensor output voltage fluctuated more than 1.5 volts.

- Battery positive voltage is more than 10.3 volts.

- Accelerator pedal is not depressed.

- Volumetric efficiency is less than 24 percent.

- The ECM monitors for this condition for 3 cycles of 1.8 seconds each during the drive cycle.

Judgment Criterion

- When the EGR valve opens to the prescribed opening, the intake manifold pressure fluctuation width is less than 2.5 kPa (0.74 in.Hg).

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Contaminated EGR valve and EGR passage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Check the EGR system

Refer to GROUP 17, Emission Control - Exhaust Gas Recirculation (EGR) System - General Information  .

.

.

.Are there any abnormalities?

STEP 2. Check the EGR valve contamination and the EGR passage contamination.

Are the EGR valve and the EGR passage clogged?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)