DTC P2530: Ignition Switch Run Position Circuit

IGNITION SWITCH-IG CIRCUIT

CIRCUIT OPERATION

- When the ignition switch is turned on, the ignition switch ON signal is input into the ECM (terminal No. 92) and also into the ETACS-ECU.

TECHNICAL DESCRIPTION

- The ECM compares the ignition switch ON signal sent from the ignition switch with ignition switch information sent from ETACS-ECU. The ECM checks for the abnormality.

DTC SET CONDITIONS

Check Condition

- Ignition switch: "ON" → "LOCK" (OFF)

Judgment Criterion

- While the ignition switch ON signal is input into the ECM, the ignition switch information, sent from the ETACS-ECU via CAN, is turned to OFF from ON. This allows the CAN to be stopped.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Shorted ignition switch-IG circuit or connector damage.

- CAN system failed.

- ETACS-ECU failed.

- ECM failed.

DIAGNOSIS

Required Special Tool:

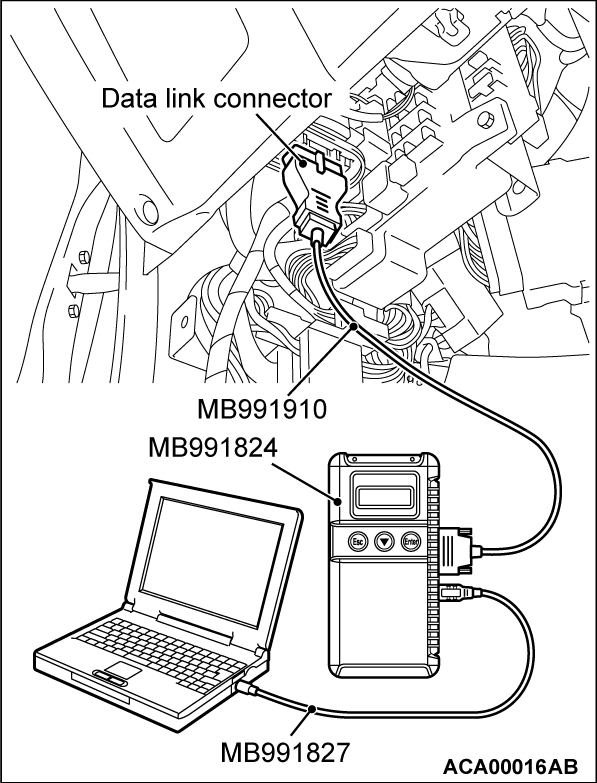

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, diagnose CAN bus line.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the CAN bus line normal?

STEP 2. Using scan tool MB991958, read the diagnostic trouble code (DTC).

(1) Turn the ignition switch to the "ON" position.

(2) Read the ETACS-DTC.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the ETACS-DTC set?

STEP 3. Check harness connector B-27 at ECM for damage.

Is the harness connector in good condition?

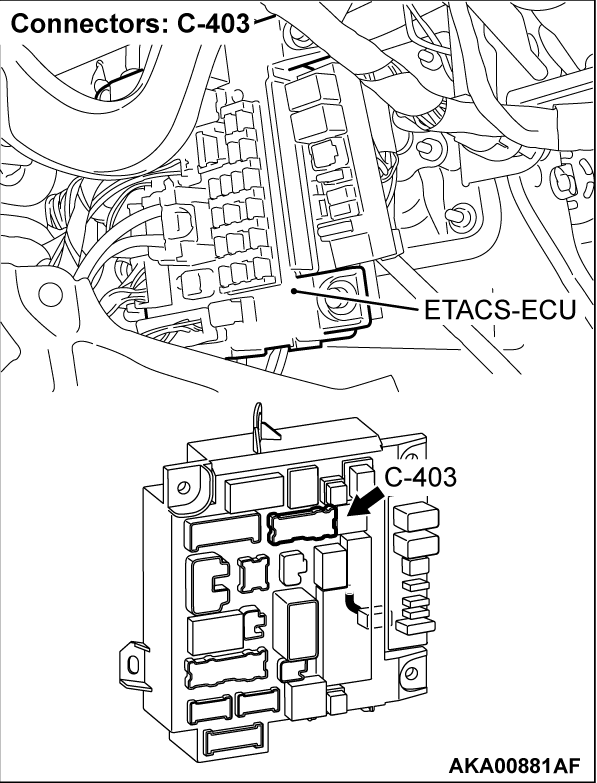

STEP 4. Check for short circuit to power supply between ETACS-ECU connector C-403 (terminal No. 10) and ECM connector B-27 (terminal No. 92).

STEP 5. Using scan tool MB991958, read the diagnostic trouble code (DTC).

(1) Turn the ignition switch ON and "LOCK" (OFF), and then leave it in the "LOCK" (OFF) position for more than 10 seconds. Place the ignition switch in the ON position again.

(2) After the MFI-DTC has been deleted, read the MFI-DTC again.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC P2530 set?

STEP 6. Replace the ETACS-ECU.

(1) Replace the ETACS-ECU.

(2) Turn the ignition switch ON and "LOCK" (OFF), and then leave it in the "LOCK" (OFF) position for more than 10 seconds. Place the ignition switch in the ON position again.

(3) After the DTC has been deleted, read the DTC again.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC P2530 set?

The inspection is complete.

The inspection is complete.STEP 7. Using scan tool MB991958, read the diagnostic trouble code (DTC).

(1) Turn the ignition switch ON and "LOCK" (OFF), and then leave it in the "LOCK" (OFF) position for more than 10 seconds. Place the ignition switch in the ON position again.

(2) After the DTC has been deleted, read the DTC again.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC P2530 set?

Retry the troubleshooting.

Retry the troubleshooting. The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)