DTC P0132: Linear Air-Fuel Ratio Sensor Circuit High Voltage

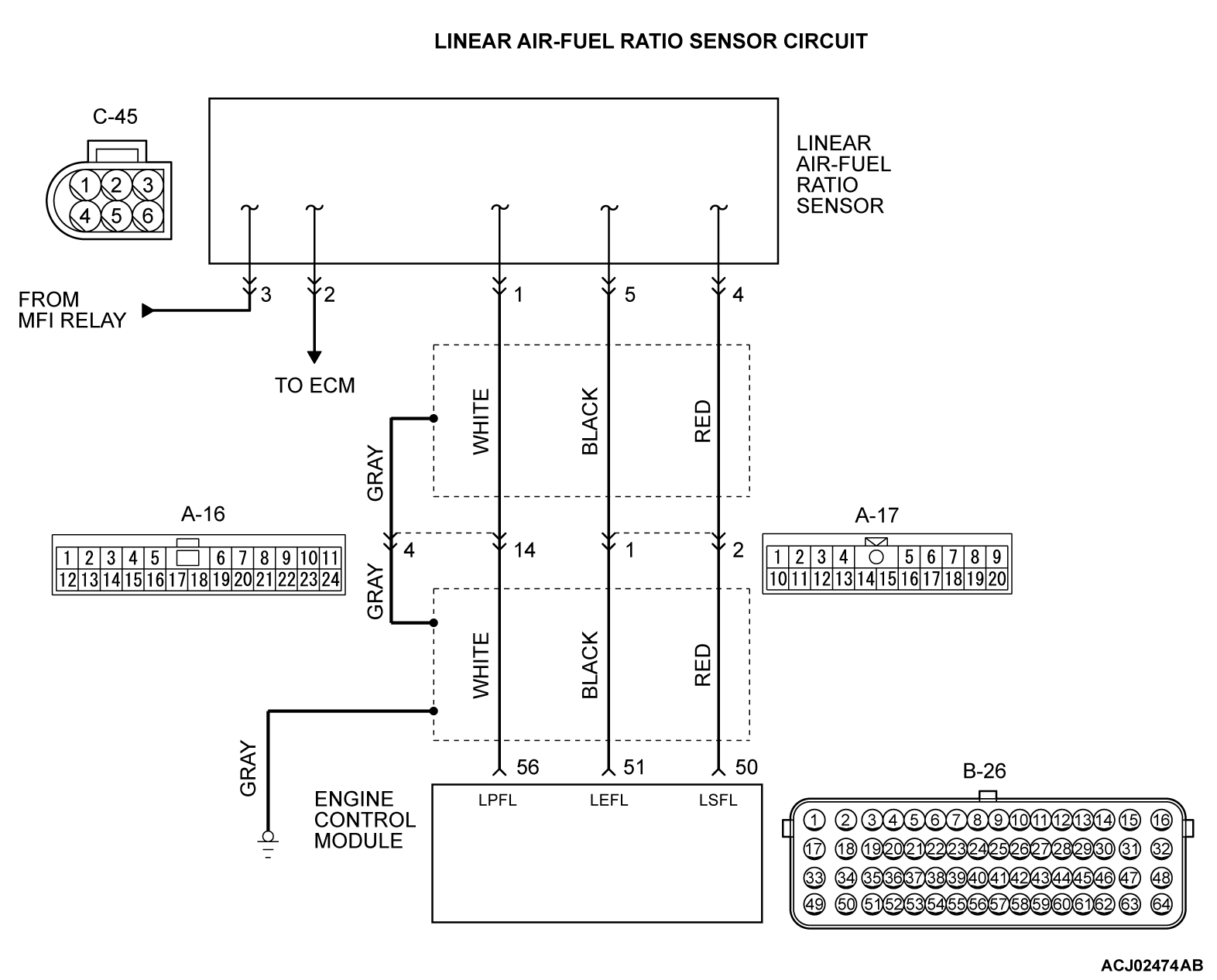

CIRCUIT OPERATION

The linear air-fuel ratio sensor and the ECM are connected by the following three lines to detect the air-fuel ratio.

- The line between the linear air-fuel ratio sensor (terminal No. 1) and the ECM (terminal No. 56) detects the air-fuel ratio.

- The auxiliary line between the linear air-fuel ratio sensor (terminal No. 4) and the ECM (terminal No. 50) detects the air-fuel ratio.

- The line between the linear air-fuel ratio sensor (terminal No. 5) and the ECM (terminal No. 51) is connected to ground.

TECHNICAL DESCRIPTION

- The ECM effects air/fuel ratio feedback control in accordance with the signals from the linear air-fuel ratio sensor.

- If the linear air-fuel ratio sensor has deteriorated, corrections will be made by the heated oxygen sensor (rear).

DESCRIPTIONS OF MONITOR METHODS

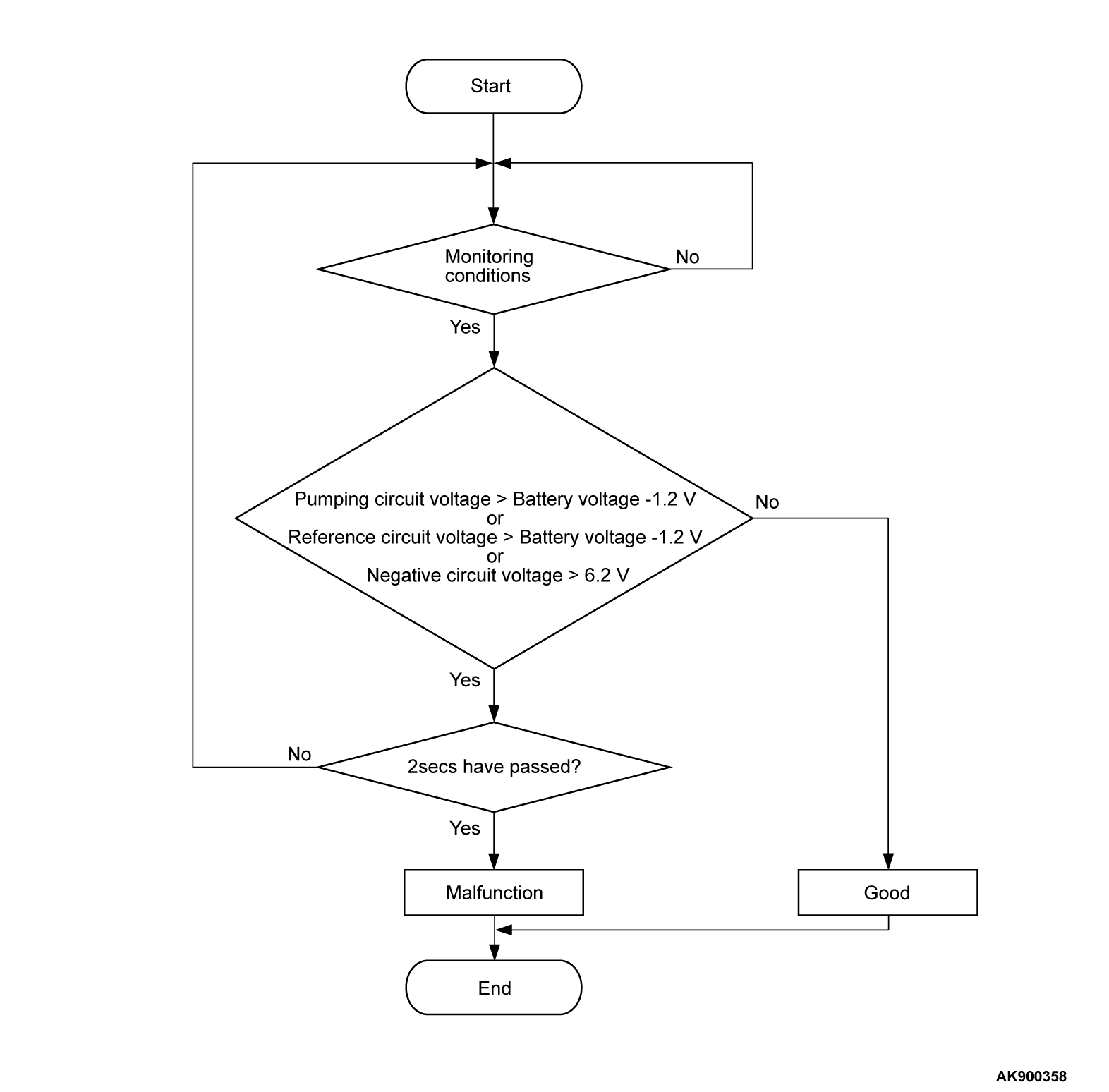

- If one of the three line voltages is excessively high or if all the three line voltages are excessively high, the DTC is set as a malfunction.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Linear air-fuel ratio sensor heater monitor

- Misfire monitor

- Fuel system monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Accelerator pedal position sensor

Check Conditions

- Battery positive voltage is between 10 and 16.5 volts.

- More than 40 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- The pumping circuit voltage is higher than the battery positive voltage from which you subtract 1.2 volt for 2 seconds.

or

- The reference circuit voltage is higher than battery positive voltage from which you subtract 1.2 volt for 2 seconds.

or

- The negative circuit voltage is be higher than 6.2 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Does not control air-fuel ratio closed loop.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Linear air-fuel ratio sensor failed.

- Shorted linear air-fuel ratio sensor circuit, or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

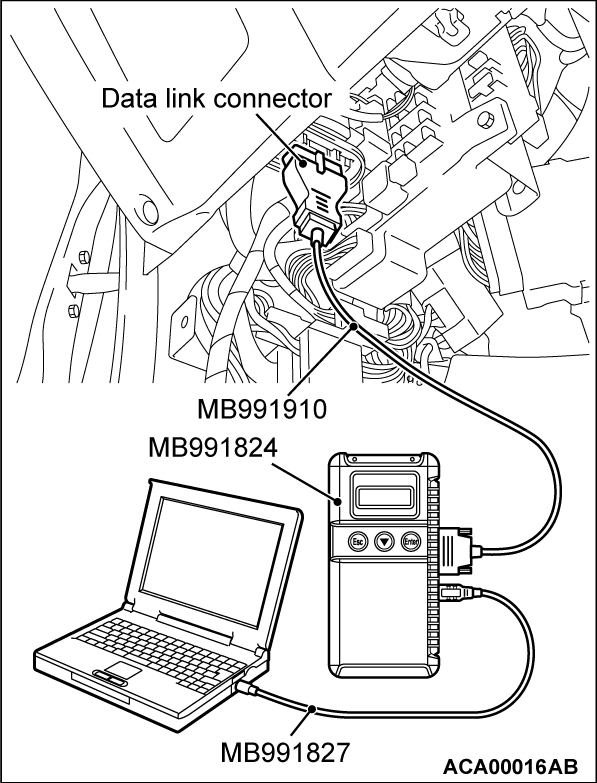

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

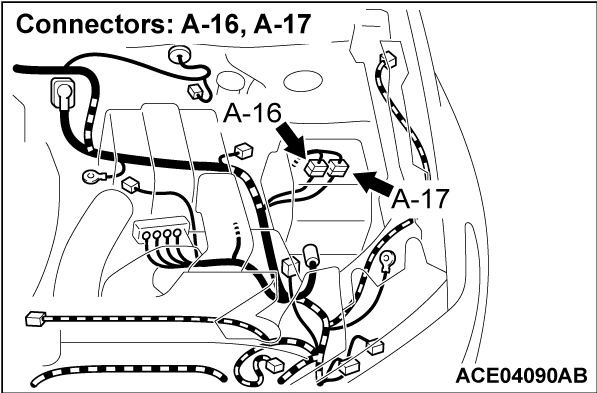

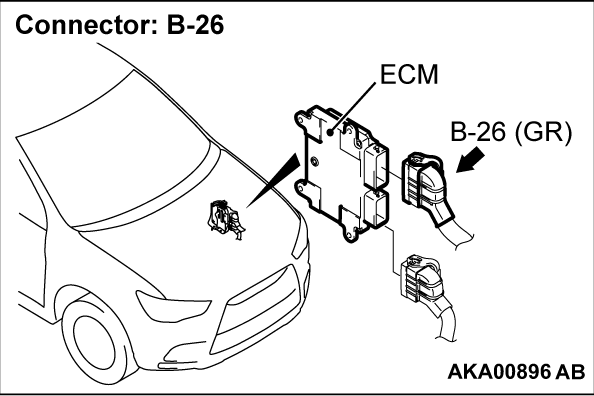

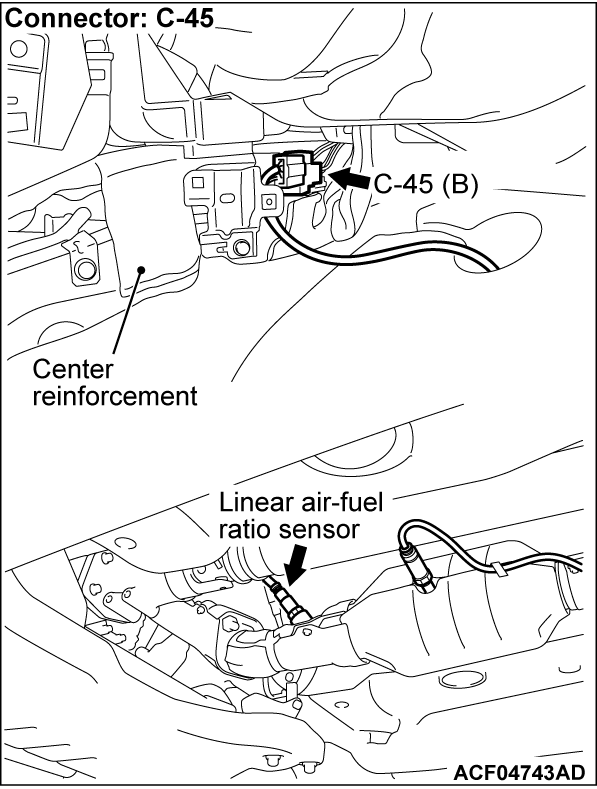

STEP 1. Check harness connector C-45 at linear air-fuel ratio sensor and harness connector B-26 at ECM for damage.

Is the harness connector in good condition?

STEP 2. Check for short circuit to power supply between linear air-fuel ratio sensor connector C-45 (terminal No. 4) and ECM connector B-26 (terminal No. 50).

STEP 3. Check for short circuit to power supply between linear air-fuel ratio sensor connector C-45 (terminal No. 1) and ECM connector B-26 (terminal No. 56).

STEP 4. Check for short circuit to power supply between linear air-fuel ratio sensor connector C-45 (terminal No. 5) and ECM connector B-26 (terminal No. 51).

STEP 5. Test the OBD-II drive cycle.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position and delete the DTC.

(3) Carry out the test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 22  .

.

.

.(4) Check the diagnostic trouble code (DTC).

Is DTC P0132 set?

STEP 6. Replace the linear air-fuel ratio sensor.

(1) Replace the linear air-fuel ratio sensor.

(2) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 22  .

.

.

.(3) Check the diagnostic trouble code (DTC).

Is DTC P0132 set?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)