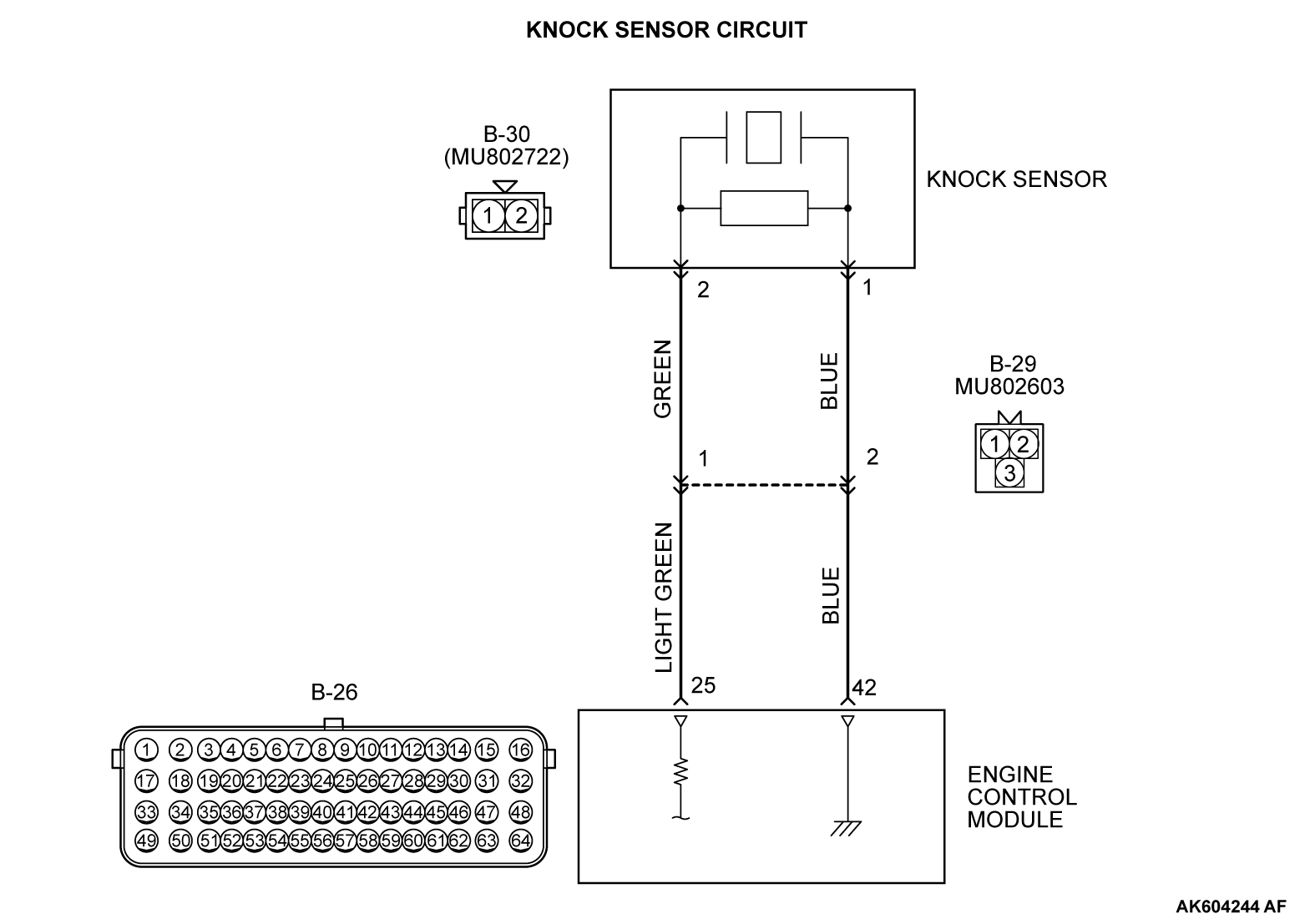

DTC P0328: Knock Sensor Circuit High

CIRCUIT OPERATION

- The knock sensor (terminal No. 2) sends a signal voltage to the ECM (terminal No. 25).

- The ground terminal (terminal No. 1) is grounded with ECM (terminal No. 42).

TECHNICAL DESCRIPTION

- The knock sensor converts the vibration of the cylinder block into a voltage and outputs it.

- The ECM checks whether the voltage is within a specified range.

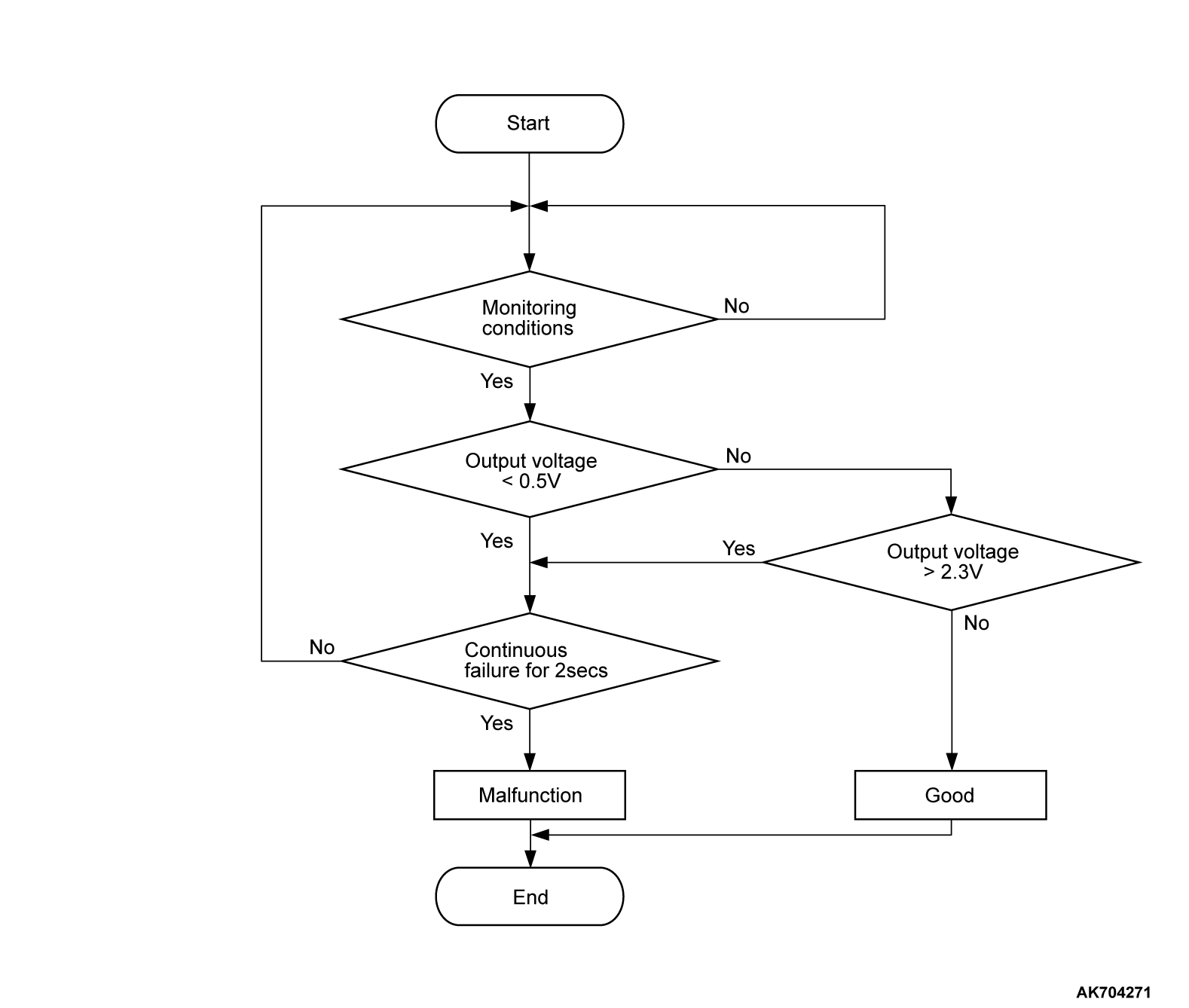

DESCRIPTIONS OF MONITOR METHODS

- Knock sensor output voltage is out of specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Condition

- More than 2 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- Knock sensor output voltage is more than 2.3 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Fix the ignition timing with an allowance against knock.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Shorted knock sensor circuit or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

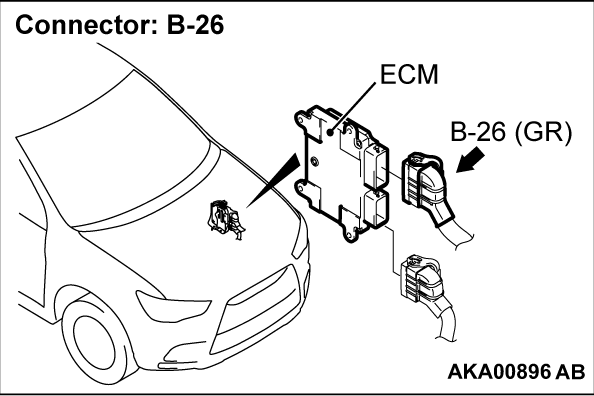

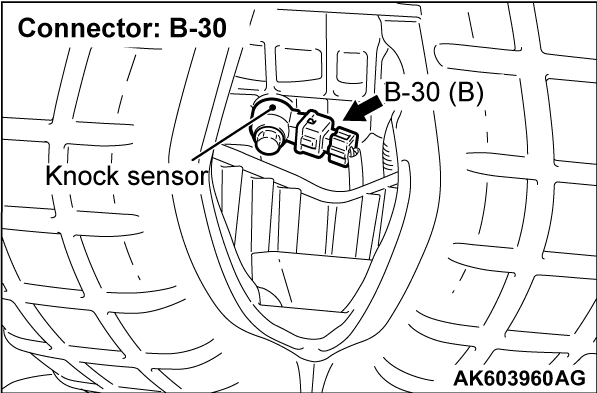

STEP 1. Check harness connector B-30 at knock sensor and harness connector B-26 at ECM for damage.

Are the harness connectors in good condition?

STEP 2. Check for short circuit to power supply between knock sensor connector B-30 (terminal No. 2) and ECM connector B-26 (terminal No. 25).

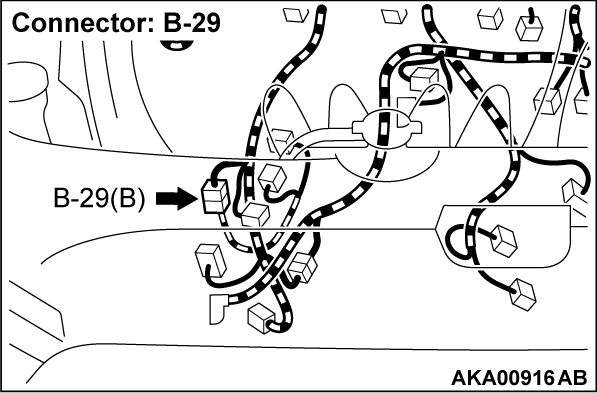

| note | Check harness after checking intermediate connector B-29. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 5. . Then go to Step 5. |

Is the harness wire in good condition?

STEP 3. Check for short circuit to power supply between knock sensor connector B-30 (terminal No. 1) and ECM connector B-26 (terminal No. 42).

| note | Check harness after checking intermediate connector B-29. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 5. . Then go to Step 5. |

Is the harness wire in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)