DTC P0182: Fuel Tank Temperature Sensor Circuit Low Input

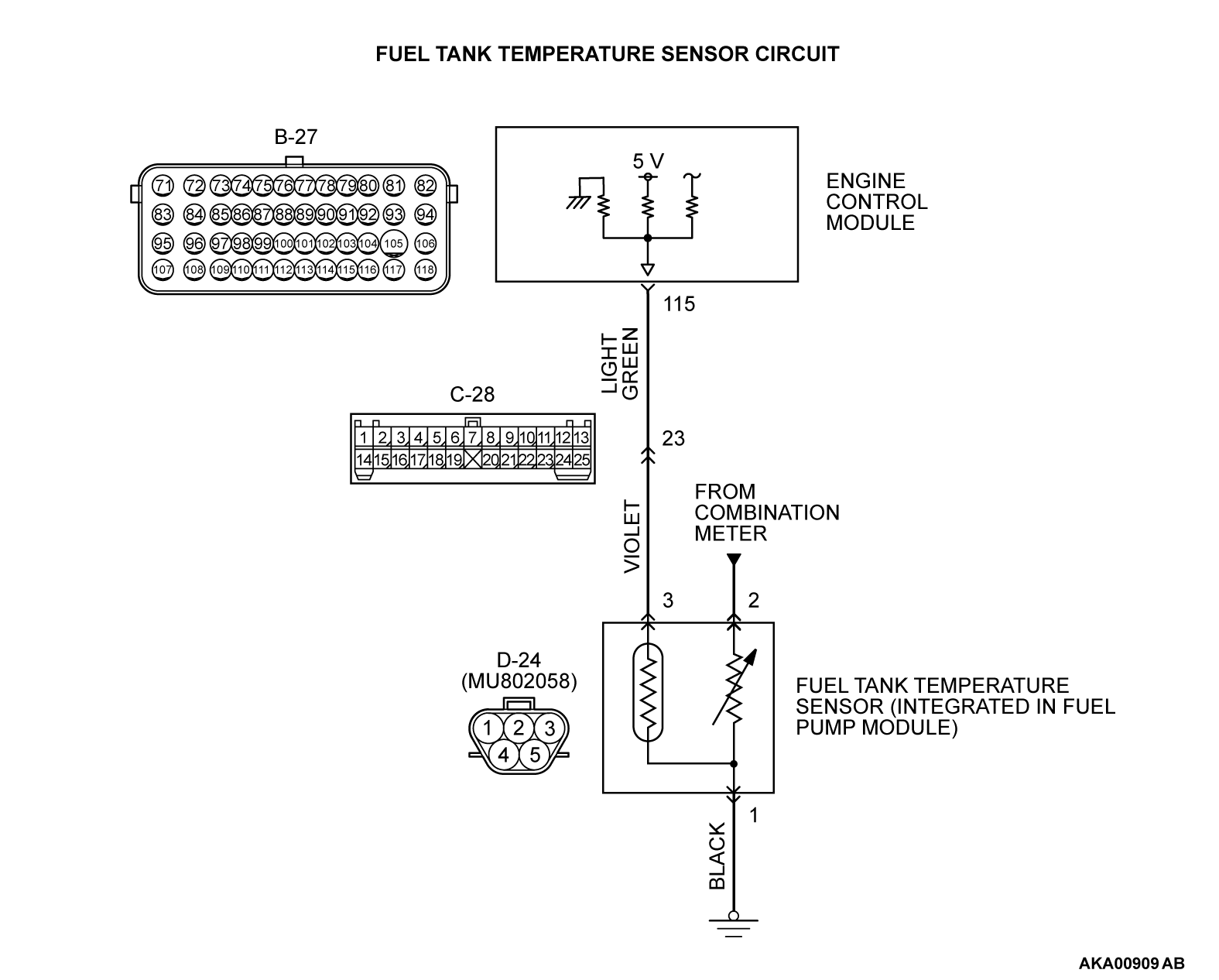

CIRCUIT OPERATION

- 5-volt voltage is applied to the fuel tank temperature sensor output terminal (terminal No. 3) from the ECM (terminal No. 115) via the resistor in the ECM.

- The fuel tank temperature sensor output voltage increases when the resistance increases and decreases when the resistance decreases. The ground terminal (terminal No. 1) is grounded to the vehicle body.

TECHNICAL DESCRIPTION

- The fuel tank temperature sensor converts the fuel tank temperature to a voltage.

- The ECM detects the fuel tank temperature with this output voltage.

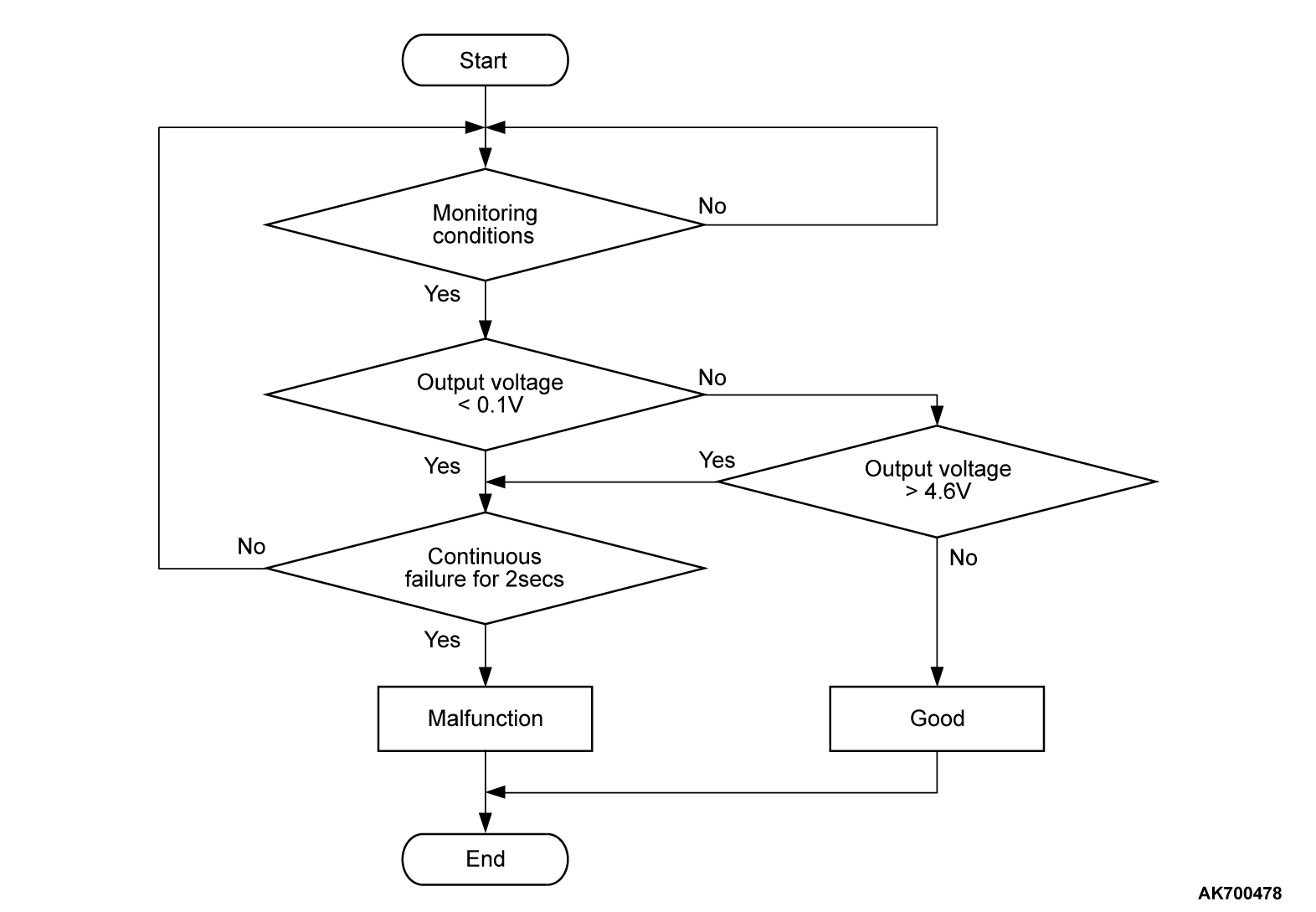

DESCRIPTIONS OF MONITOR METHODS

- Fuel tank temperature sensor output voltage is out of specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

Check Condition

- More than 2 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- Fuel tank temperature sensor output voltage is less than 0.1 volt for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Fuel tank temperature sensor failed.

- Shorted fuel tank temperature sensor circuit or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

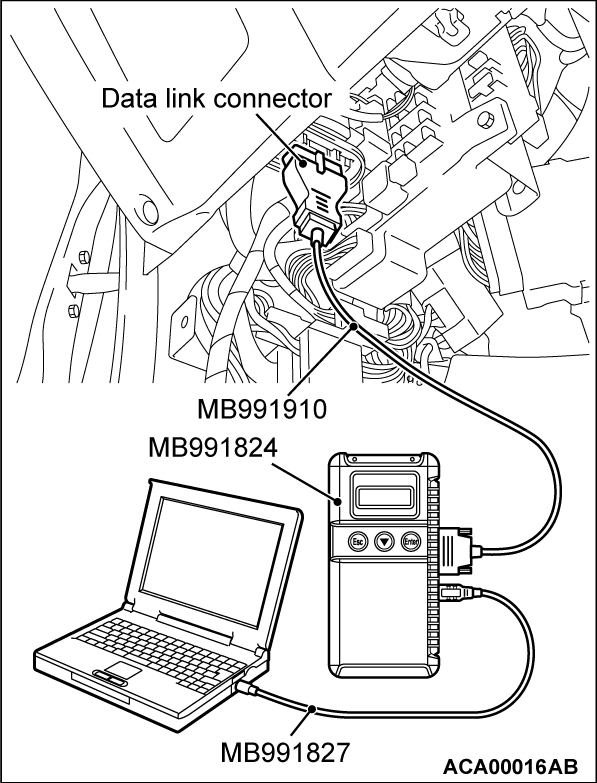

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check data list item 53: Fuel Tank Temperature Sensor.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool MB991958 to the data reading mode for item 53, Fuel Tank Temperature Sensor.

- Approximately the same as the ambient air temperature when the engine is cooled.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

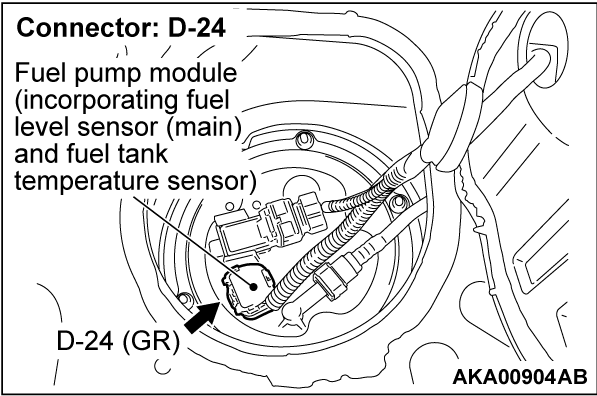

STEP 2. Check harness connector D-24 at fuel pump module for damage.

Is the harness connector in good condition?

STEP 3. Check the fuel tank temperature sensor.

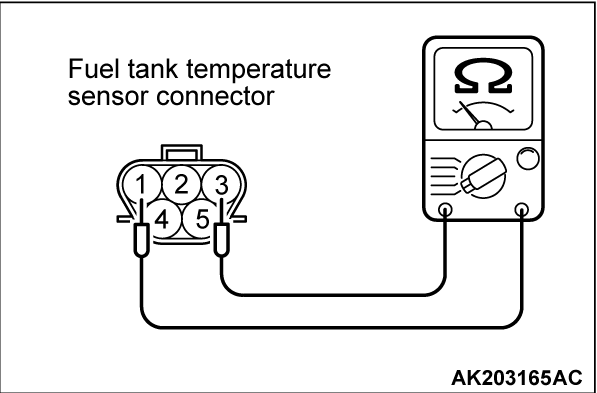

(1) Disconnect the fuel pump module connector D-24.

(2) Measure the resistance between terminal No. 1 and No. 3 of the fuel pump module.

Standard value: 0.5 - 12.0 kΩ

Is the measured resistance between 0.5 and 12.0 kΩ?

STEP 4. Check harness connector B-27 at ECM for damage.

Is the harness connector in good condition?

STEP 5. Check for short circuit to ground between fuel pump module connector D-24 (terminal No. 3) and ECM connector B-27 (terminal No. 115).

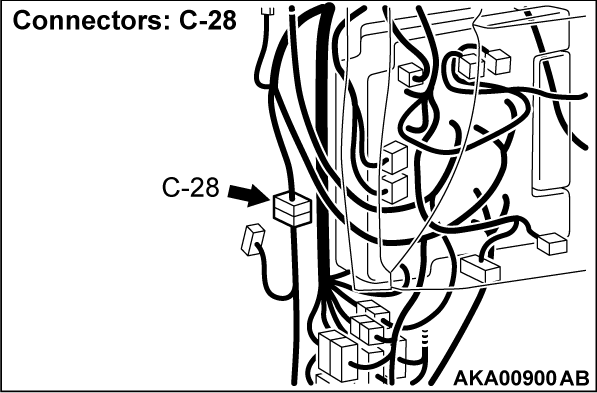

| note | Check harness after checking intermediate connector C-28. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 7. . Then go to Step 7. |

Is the harness wire in good condition?

STEP 6. Using scan tool MB991958, check data list item 53: Fuel Tank Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 53, Fuel Tank Temperature Sensor.

- Approximately the same as the ambient air temperature when the engine is cooled.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)