DTC P0111: Intake Air Temperature Circuit Range/Performance Problem

CIRCUIT OPERATION

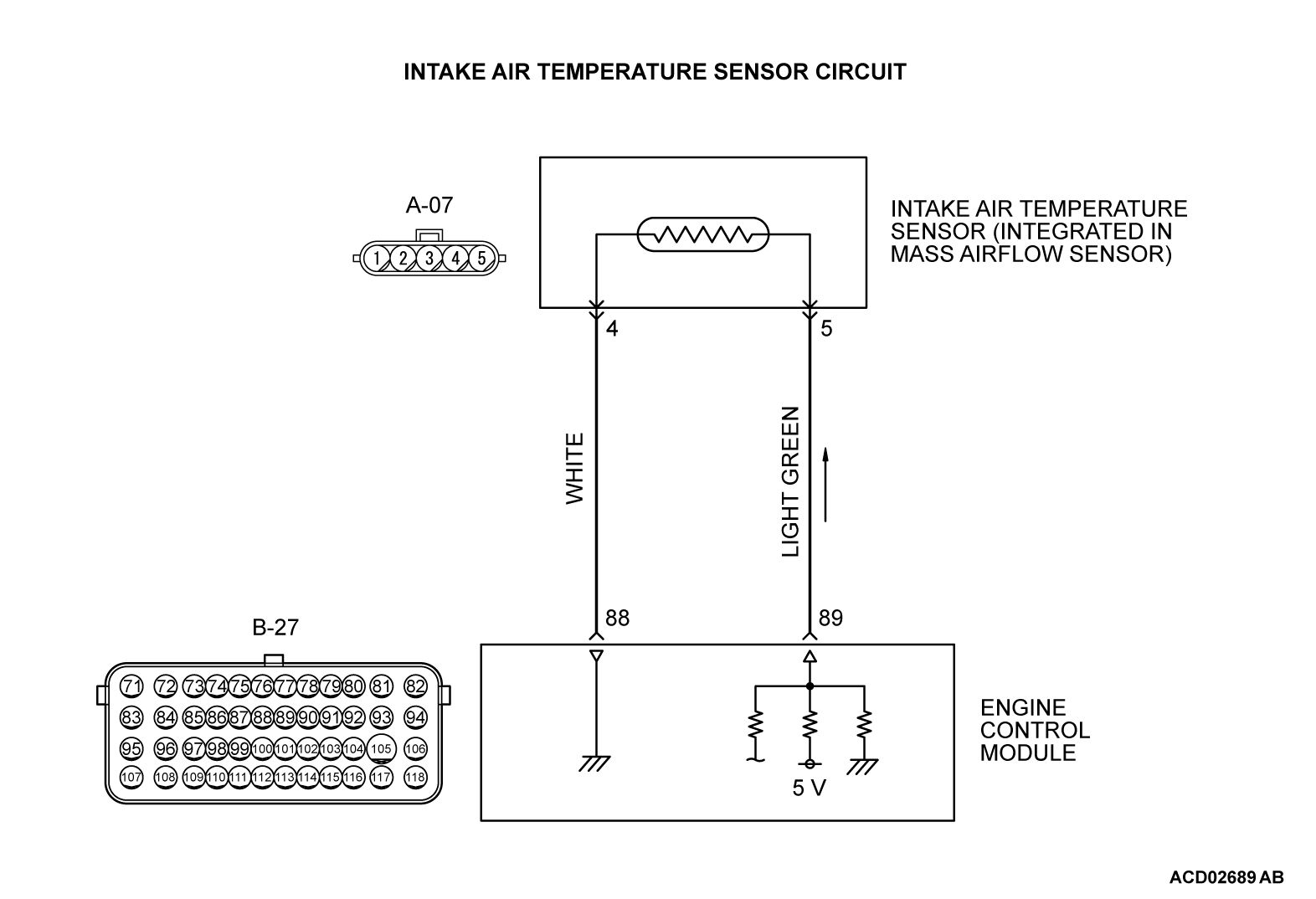

- Approximately 5 volts are applied to the intake air temperature sensor output terminal (terminal No. 1) from the ECM (terminal No. 89) via the resistor in the ECM. The ground terminal (terminal No. 4) is grounded with ECM (terminal No. 88).

- The intake air temperature sensor is a negative temperature coefficient type of resistor. When the intake air temperature rises, the resistance decreases.

- The intake air temperature sensor output voltage increases when the resistance increases and decreases when the resistance decreases.

TECHNICAL DESCRIPTION

- The intake air temperature sensor converts the intake air temperature to a voltage.

- The ECM checks whether this voltage is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

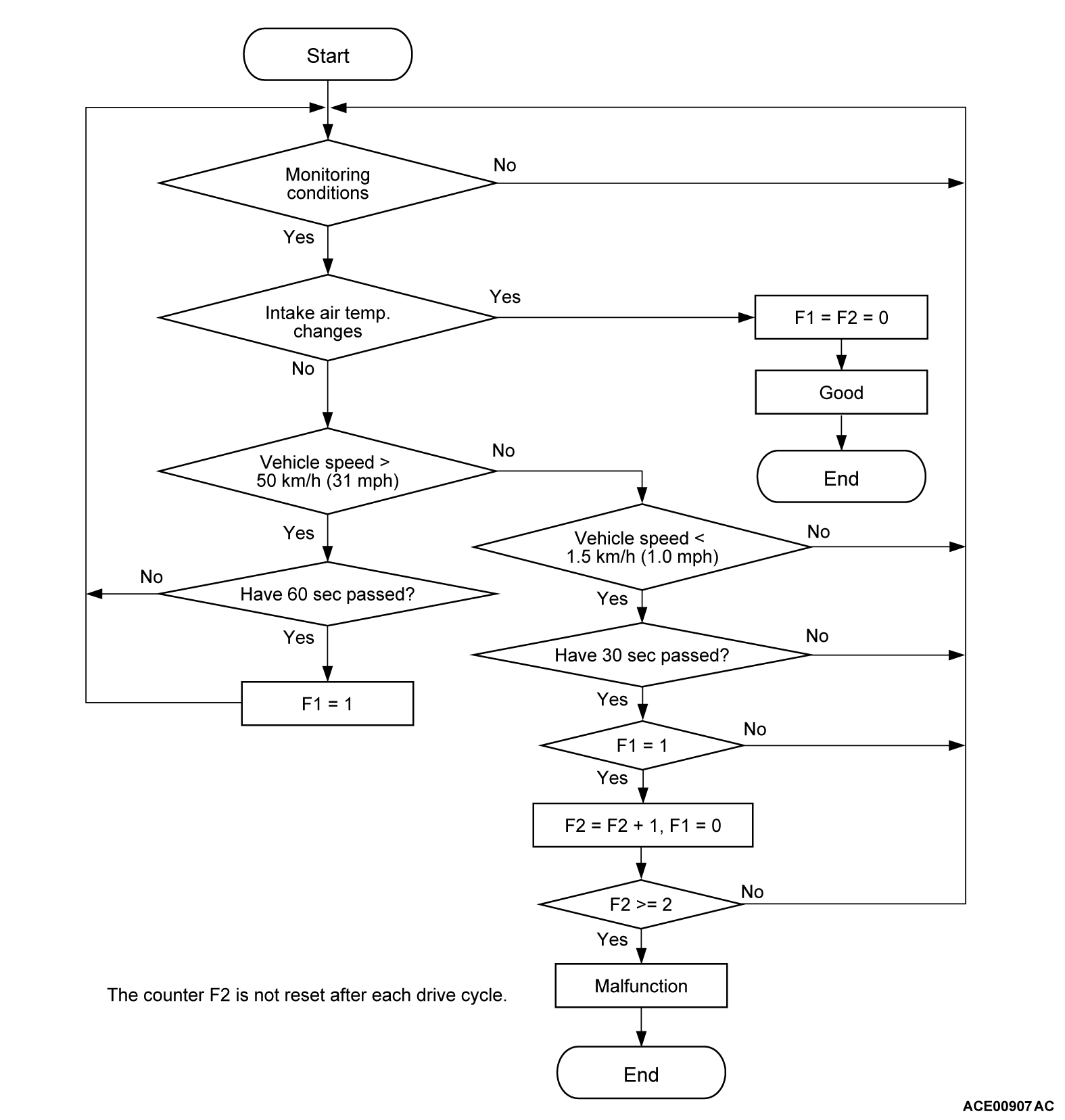

- Intake air temperature sensor output voltage does not change when specified go/stop operations are repeated.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Engine coolant temperature sensor

Check Conditions

- Engine coolant temperature is more than 76°C (169°F).

- Repeat 2 times or more: drive*1, stop*2.

- Drive*1:

- Vehicle speed is more than 50 km/h (31 mph) lasting a total of 60 seconds or more.

- Stop*2:

- Vehicle speed is less than 1.5 km/h (1.0 mph) lasting 30 seconds or more.

Judgment Criterion

- Changes in the intake air temperature is less than 1°C (1.8°F).

FAIL-SAFE AND BACKUP FUNCTION

- Control as if the intake air temperature is 25°C (77°F).

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Intake air temperature sensor failed.

- Harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

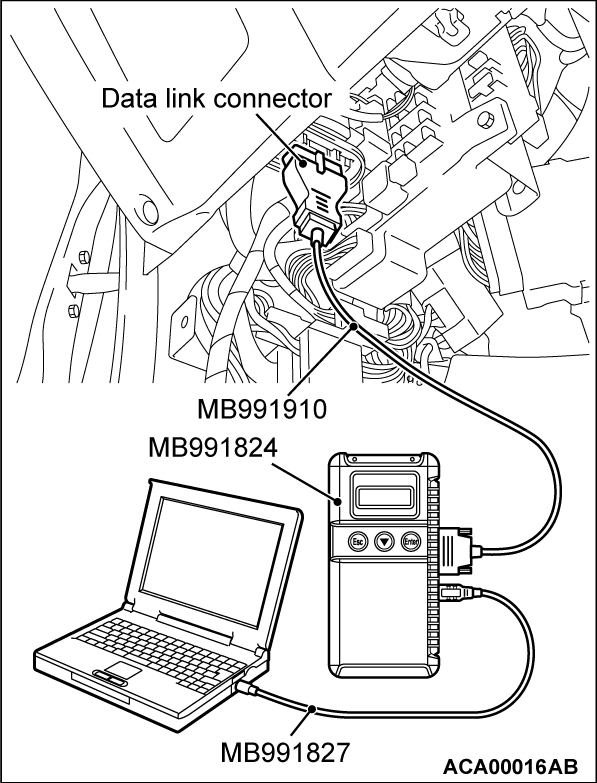

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check data list item 5: Intake Air Temperature Sensor.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

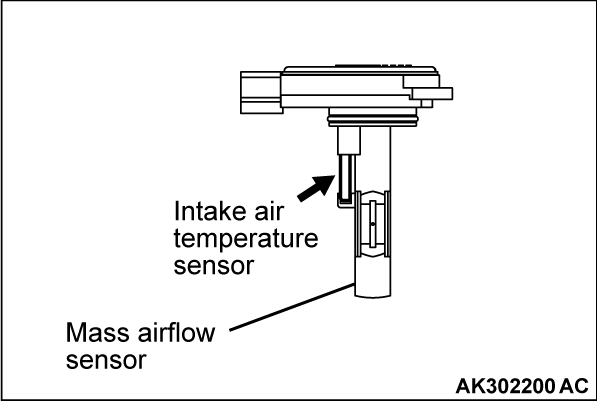

(2) Remove the mass airflow sensor from the air intake hose.

(3) Turn the ignition switch to the "ON" position.

(4) Set scan tool MB991958 to the data reading mode for item 5, Intake Air Temperature Sensor.

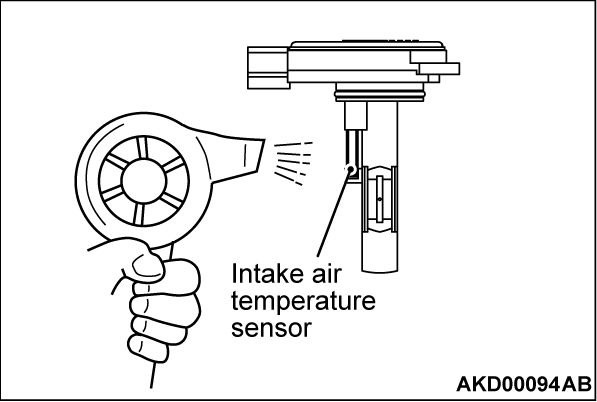

(5) Heating the sensor using a hair drier.

- The indicated temperature increases.

note Do not allow it to increase over 80°C (176°F).

(6) Turn the ignition switch to the "LOCK" (OFF) position.

(7) Attach the mass airflow sensor.

Is the sensor operating properly?

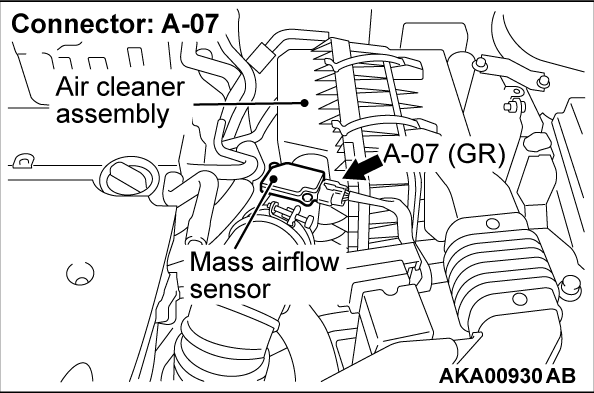

STEP 2. Check harness connector A-07 at intake air temperature sensor for damage.

Is the harness connector in good condition?

STEP 3. Check the intake air temperature sensor.

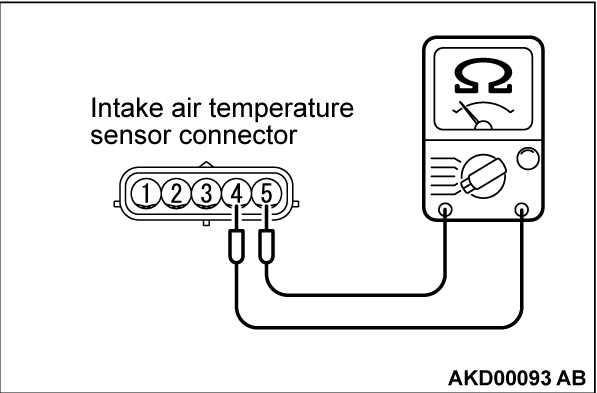

(1) Disconnect the intake air temperature sensor connector A-07.

(2) Measure resistance between terminal No. 4 and No. 5.

Standard value:

- 13 - 18 kΩ [at -20°C (-4°F)]

- 5.3 - 6.7 kΩ [at 0°C (32°F)]

- 2.3 - 3.0 kΩ [at 20°C (68°F)]

- 0.30 - 0.45 kΩ [at 80°C (176°F)]

If not within specifications, replace the mass airflow sensor.

(3) Measure resistance while heating the sensor using a hair drier.

Normal condition:

| TEMPERATURE | RESISTANCE (kΩ) |

| Higher | Smaller |

If resistance does not decrease as heat increases, replace the mass airflow sensor.

Is the measured resistance at the standard value?

STEP 4. Check the continuity at intake air temperature sensor harness side connector A-07.

(1) Disconnect the connector A-07 and measure at the harness side.

(2) Check for the continuity between terminal No. 4 and ground.

- Continuity (2 ohms or less)

Does continuity exist?

STEP 5. Check harness connector B-27 at ECM for damage.

Is the harness connector in good condition?

STEP 6. Check for harness damage between intake air temperature sensor connector A-07 (terminal No. 4) and ECM connector B-27 (terminal No. 88).

STEP 7. Check harness connector B-27 at ECM for damage.

Is the harness connector in good condition?

STEP 8. Check for harness damage between intake air temperature sensor connector A-07 (terminal No. 5) and ECM connector B-27 (terminal No. 89).

STEP 9. Using scan tool MB991958, check data list item 5: Intake Air Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 5, Intake Air Temperature Sensor.

- The intake air temperature and temperature shown with the scan tool should approximately match.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)