DTC P014C: Linear Air-Fuel Ratio Sensor Circuit Slow Response - Rich to Lean

TECHNICAL DESCRIPTION

- The ECM effects air/fuel ratio feedback control in accordance with the signals from the linear air-fuel ratio sensor.

- If the linear air-fuel ratio sensor has deteriorated, corrections will be made by the heated oxygen sensor (rear).

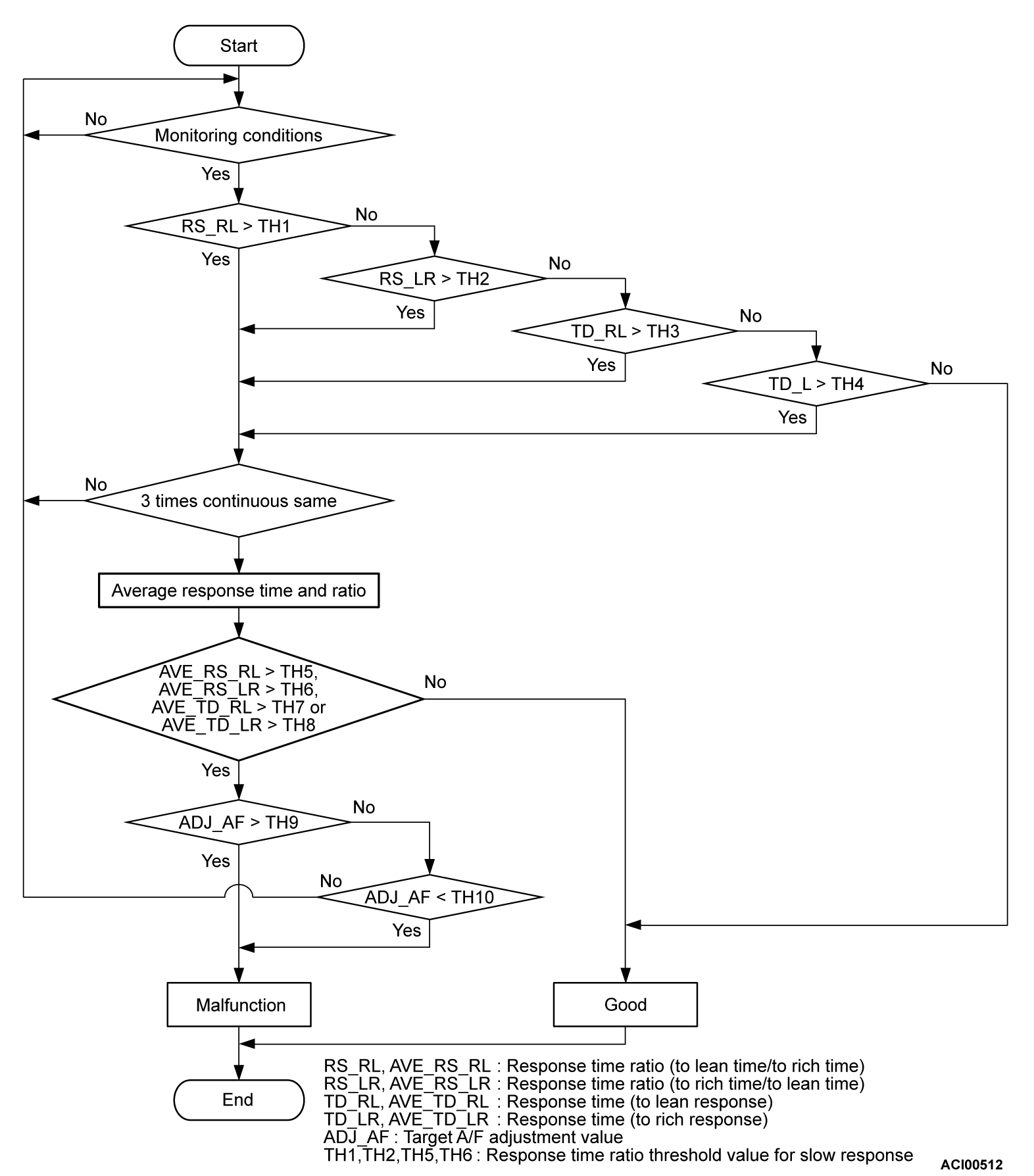

DESCRIPTIONS OF MONITOR METHODS

- When the average of the difference between the response times of the rich side and the lean side of the linear air-fuel ratio sensor during the monitoring time becomes equal to or higher than the predetermined value, the DTC is set as the linear air-fuel ratio sensor deterioration.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Linear air-fuel ratio sensor heater monitor

- Misfire monitor

- Fuel system monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Accelerator pedal position sensor

Check Conditions

- Engine speed is between 1,219 and 3,000 r/min.

- Volumetric efficiency is between 25.0 and 85.0 percent.

- Mass airflow sensor output is 9 g/sec or more.

- Engine coolant temperature is more than 60°C (140°F).

- Under the closed loop air/fuel control.

- The accelerator pedal is depressed.

- Short-term fuel trim is between -25 and +25 percent.

- More than 3 seconds have passed after the above mentioned conditions have been met.

- During the drive cycle, the ECM performs monitoring with the accumulated total time of 10 seconds, 3 times.

Judgment Criteria

- The average response time ratio (to lean time/to rich time) is more than specified value.

- The amount of compensated air/fuel ratio based on the heated oxygen sensor (rear) is out of specified amount.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Linear air-fuel ratio sensor failed.

DIAGNOSIS

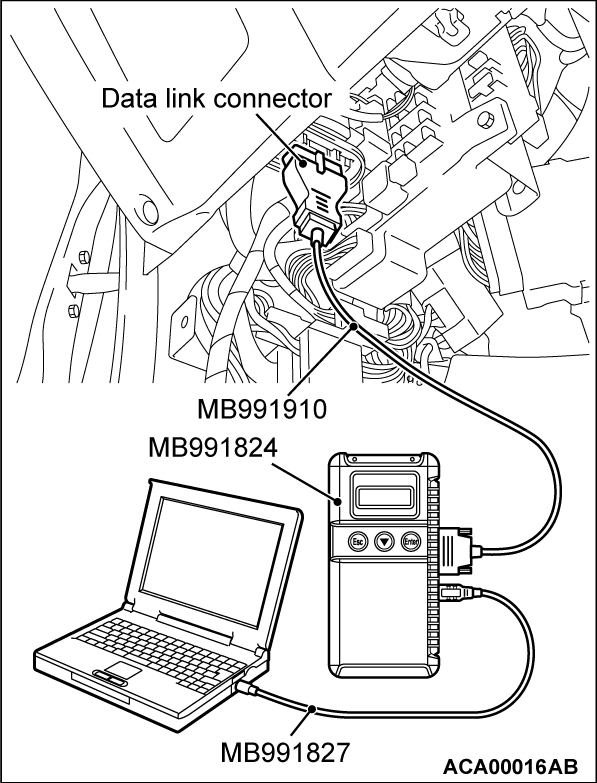

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Test the OBD-II drive cycle.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position and delete the DTC.

(3) Carry out the test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 1  .

.

.

.(4) Check the diagnostic trouble code (DTC).

Is DTC P014C set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)