POST-COLLISION DIAGNOSIS

To inspect and service the SRS after a collision (whether or not the air bags have deployed), perform the following steps.

SRS-ECU MEMORY CHECK

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

1.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

Connect scan tool MB991958 to the data link connector (16-pin).

2. Read (and write down) all displayed diagnostic trouble codes (Refer to  ).

).

).

).| note | If the battery power supply has been disconnected or disrupted by the collision, scan tool MB991958 cannot communicate with the SRS-ECU. Check the battery, then check and, if necessary, repair the front wiring harness and the instrument panel wiring harness before proceeding. |

3. Read the data list (fault duration and how many times memories are erased), using scan tool MB991958 (Refer to  ).

).

).

).4. Erase the diagnostic trouble codes, and then turn the ignition switch to the LOCK (OFF) position.

5. Wait for at least one second, and then turn the ignition switch to the ON position again.

REPAIR PROCEDURE

WHEN FRONT AIR BAGS DEPLOY IN A COLLISION.

1. Replace the following parts with new ones:

- SRS-ECU (Refer to

).

). - Driver's air bag module (Refer to

).

). - Passenger's (front) air bag module (Refer to

).

). - Knee air bag module (Refer to

).

). - Seat belt with pre-tensioner (Refer to

).

). - Front impact sensors (Refer to

).

). - Instrument trim assembly (Refer to GROUP 52A - Instrument Panel Assembly

).

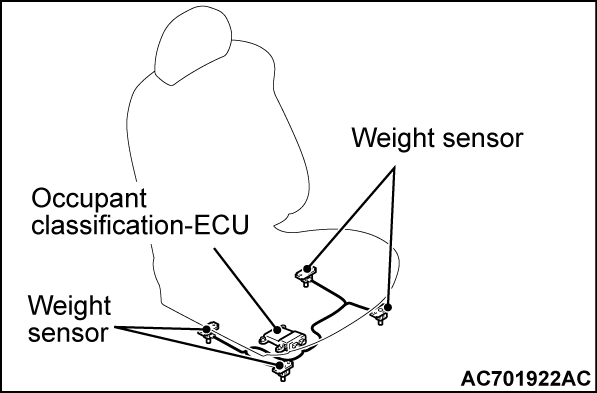

). - Front passenger’s seat cushion frame assembly (Occupant classification-ECU and weight sensor) (Refer to GROUP 52A, Front Seat Assembly

).

).

2. Check the following parts. If there is an abnormality, replace with new parts.

WHEN SIDE AND CURTAIN AIR BAGS DEPLOY IN A COLLISION.

1. Replace the following parts with new ones.

- SRS-ECU (Refer to

).

). - Front seatback assembly (Refer to

).

). - Curtain air bag module (Refer to

).

). - Side impact sensor (front and rear) (Refer to

).

). - Headlining (Refer to GROUP 52A, Headlining

).

). - Front pillar trim, center pillar trim upper, quarter trim upper (Refer to GROUP 52A - Interior Trim

).

). - Seat belt with pre-tensioner (Refer to

).

).

WHEN CURTAIN AIR BAGS DEPLOY IN A COLLISION.

1. Replace the following parts with new ones:

WHEN CURTAIN AIR BAGS DEPLOY AND SEAT BELT PRE-TENSIONER OPERATE IN A COLLISION.

1. Replace the following parts with new ones:

WHEN AIR BAGS DO NOT DEPLOY IN LOW-SPEED COLLISION.

Check the SRS components. If the SRS components are showing any visible damage such as dents, cracks, or deformation, replace them with new ones. Concerning parts removed for inspection, replacement with new parts and cautionary points for working, refer to appropriate INDIVIDUAL COMPONENT SERVICE  .

.

.

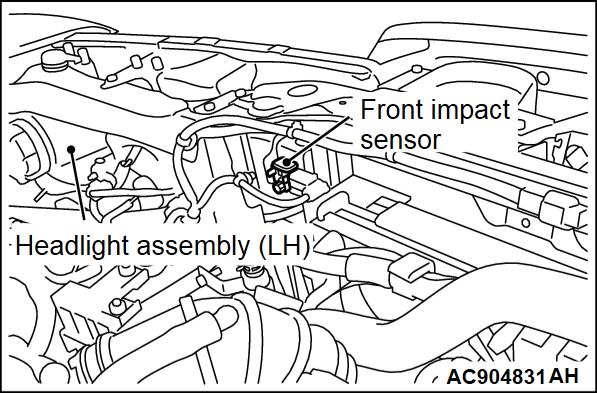

.FRONT IMPACT SENSOR

1. Check the front end upper bar for distortion and rust.

2. Check the front impact sensor for dents, cracks, deformation or rust.

3. Check the front impact sensor wiring harness for binding, check the connector for damage, and check the terminals for deformation.

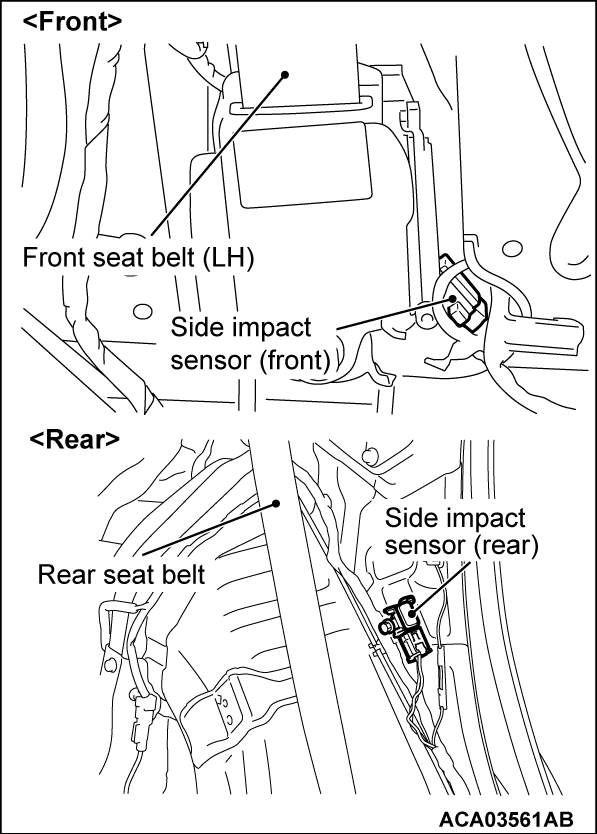

| note | The illustration shows the side impact sensor (RH). The position of the side impact sensor (LH) is symmetrical to this. |

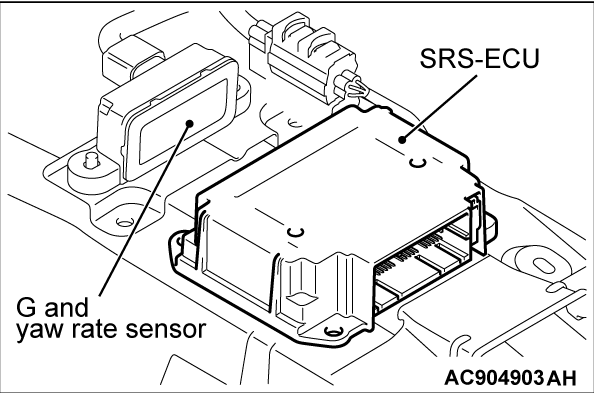

SRS-ECU

1. Check the SRS-ECU case and brackets for dents, cracks or deformation.

2. Check the connector for damage, and the terminals for deformation.

3. Check the installation of the SRS-ECU and its bracket.

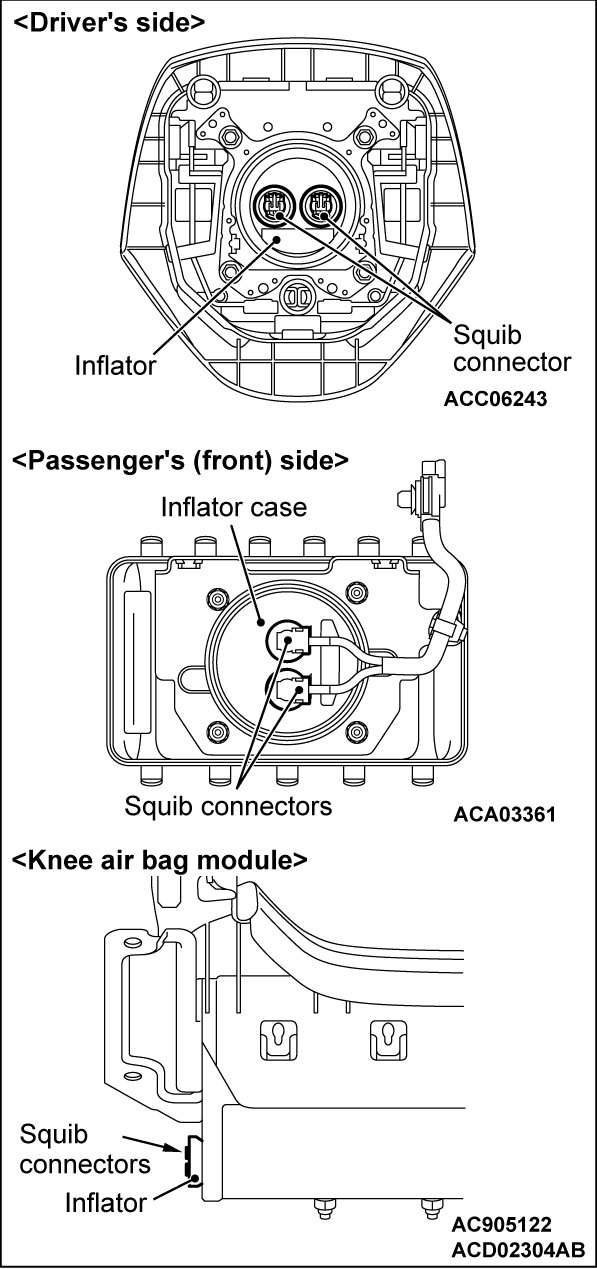

DRIVER'S AND PASSENGER'S (FRONT) AIR BAG MODULE, DRIVER'S KNEE AIR BAG MODULE

1. Check the pad cover for dents, cracks or deformation.

2. Check the connector for damage, terminal deformities, and the harness for binding.

3. Check the air bag inflator case for dents, cracks or deformities.

4. Check that the air bag module is installed correctly.

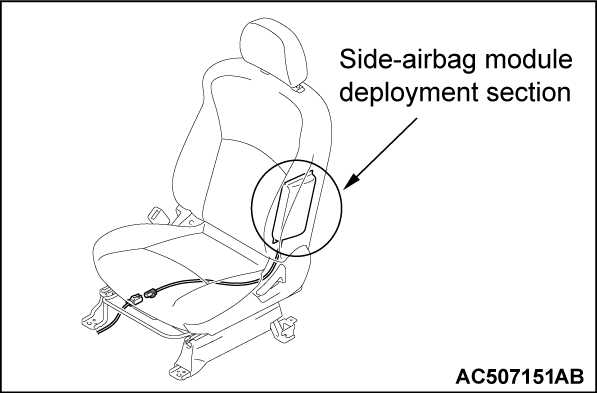

FRONT SEATBACK ASSEMBLY (SIDE-AIR BAG MODULE)

1. Check the air bag module deployment section for dents or deformation.

2. Check that there is no connector damage, bent terminals or harness crimping.

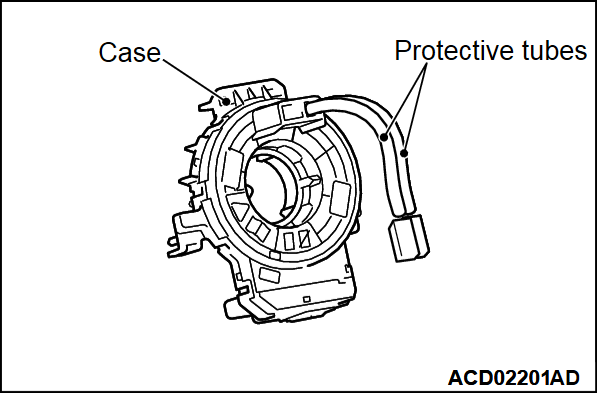

CLOCK SPRING

1. Check the clock spring connectors and protective tube for damage, and the terminals for deformation.

2. Visually check the case for damage.

SIDE IMPACT SENSOR

1. Check that there is no bending or corrosion in the center pillar and quarter panel.

2. Check that there is no denting, breakage or bending of the side impact sensor.

3. Check that there is no harness crimping, connector damage or bent terminals.

| note | The illustration shows the side impact sensor (RH). The position of the side impact sensor (LH) is symmetrical to this. |

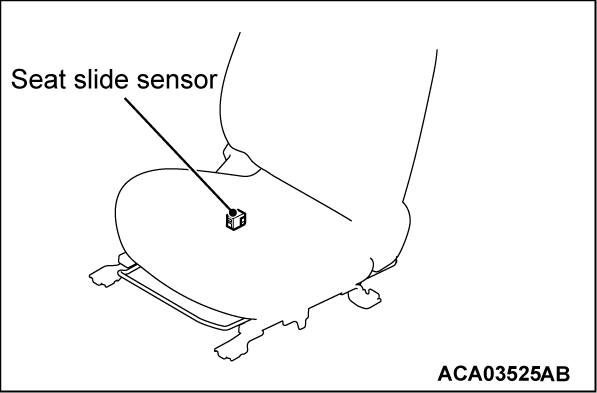

SEAT SLIDE SENSOR

1. Check that there is no connector damage, bent terminals or harness crimping.

2. Check the installation of the seat slide sensor.

OCCUPANT CLASSIFICATION-ECU AND WEIGHT SENSOR

1. Check the occupant classification-ECU case and weight sensor for dents, cracks or deformation.

2. Check the connector for damage, and the terminals for deformation.

3. Check the installation of the occupant classification-ECU and weight sensor.

4. Check the diagnostic trouble code of occupant classification-ECU and replace the seat cushion frame assembly <passenger’s side> if DTC B1BA7 is stored.

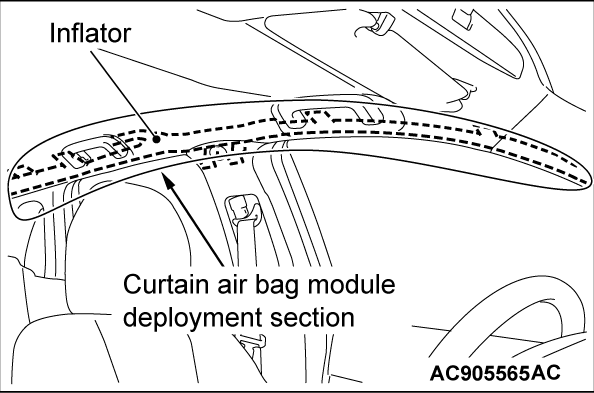

CURTAIN AIR BAG MODULE

1. Check that the curtain air bag deployment part of the headlining is normal.

2. Check the inflator surface for cracks, dents or deformations.

3. Check the connector for damage, the terminal for deformation, and the harness for binding.

STEERING WHEEL, STEERING COLUMN AND SHAFT ASSEMBLY

1. Check the wiring harness (built into the steering wheel) and the connectors for damage, and the terminals for deformation.

2. Install the air bag module to check fit or alignment with the steering wheel.

3. Check the steering wheel for noise, binding or difficult operation and excessive free play.

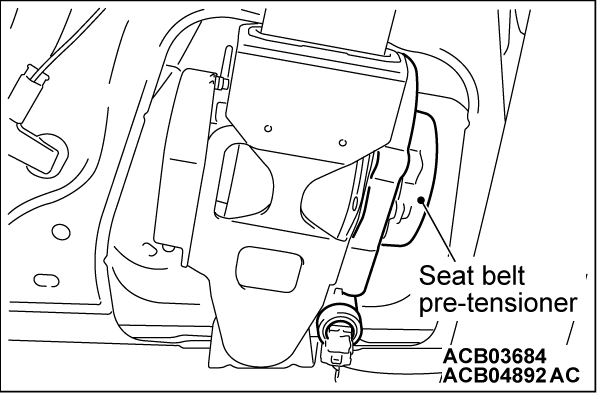

SEAT BELT WITH PRE-TENSIONER

1. Check the seat belt for damage or deformation.

2. Check the seat belt with pre-tensioner for cracks or deformation.

3. Check that the unit is installed correctly to the vehicle body.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)