DTC U0001: Malfunction of CAN Communication Circuit

DIAGNOSTIC FUNCTION

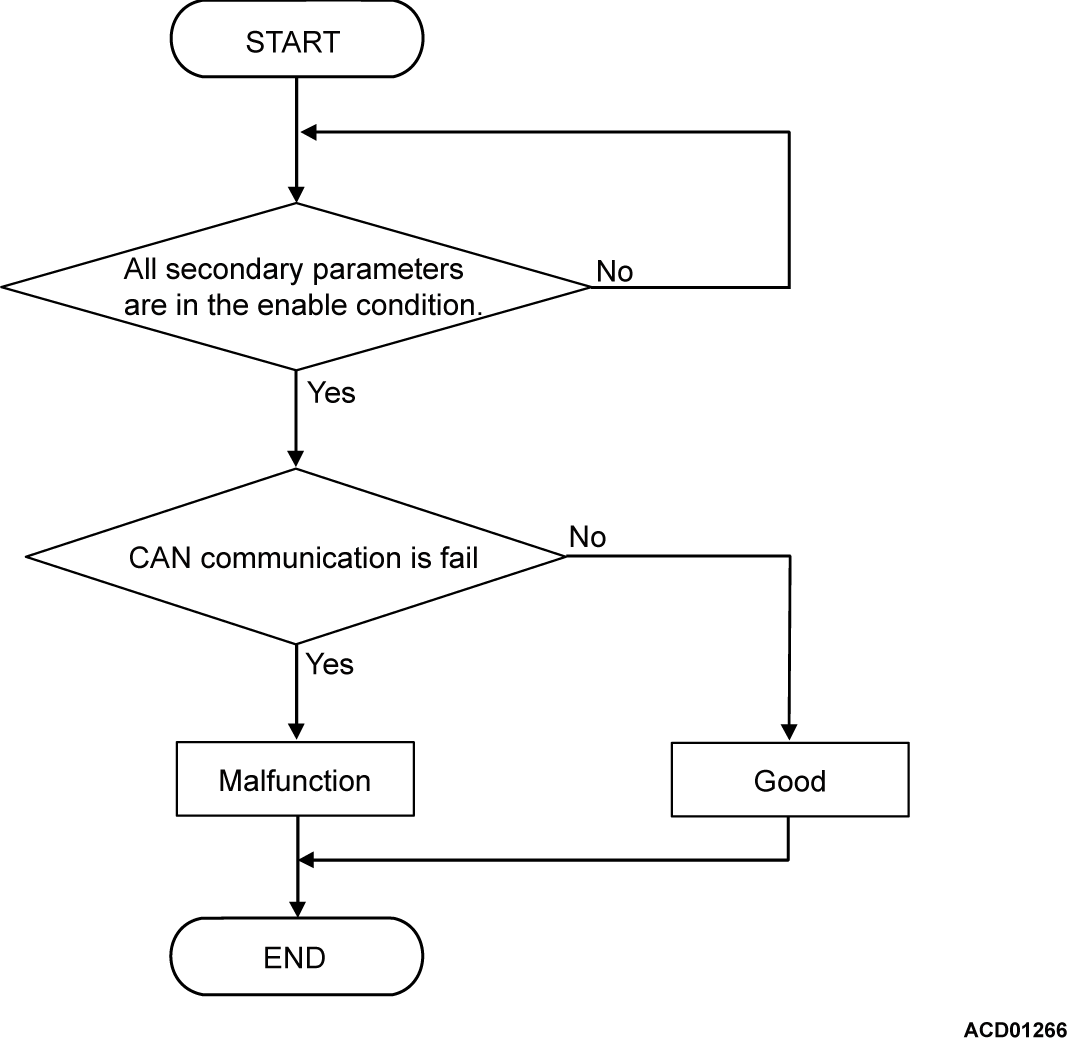

TCM conducts bus-off detection.

DESCRIPTIONS OF MONITOR METHODS

- TCM cannot receive the periodic communication data.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0703: Malfunction of stoplight switch

- P0705: Malfunction of transmission range switch

- P0712, P0713: Malfunction of the transmission fluid temperature sensor

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of secondary pulley speed sensor

- P0725: Malfunction of engine speed

- P0740: Malfunction of lockup solenoid valve

- P0745: Malfunction of line pressure solenoid valve

- P0840: Malfunction of secondary pressure sensor

- P1777: Malfunction of stepper motor

Sensor (The sensor below is determined to be normal)

- Stoplight switch

- Transmission range switch

- Primary pulley speed sensor

- Secondary pulley speed sensor

- Secondary pressure sensor

DTC SET CONDITIONS

Check Conditions

- Time after TCM start: more than 1.05 seconds.

- Voltage of battery: 9 volts or more

- Voltage of battery: 16 volts or less

Judgment Criteria

- CAN communication: fail

OBD-II DRIVE CYCLE PATTERN

Ignition switch: ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of the CAN bus

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)