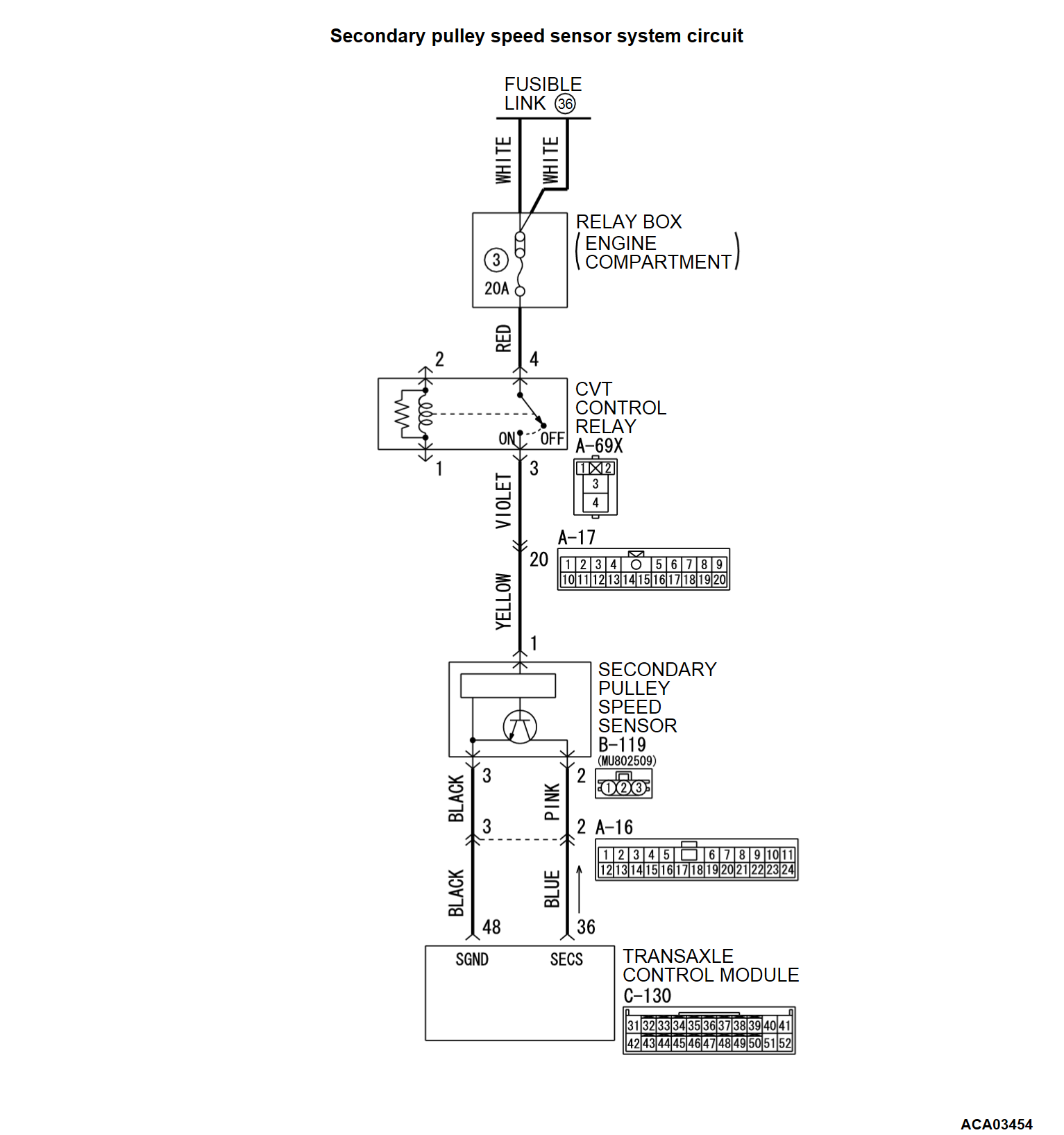

DTC P0720: Malfunction of Secondary Pulley Speed Sensor

DIAGNOSTIC FUNCTION

TCM determines that the malfunction is present when the secondary pulley speed sensor value changes abruptly or when there is a discrepancy between this sensor and other sensors in sensor reading.

DESCRIPTIONS OF MONITOR METHODS

- The status with the primary pulley speed of 1,000 r/min or more and with the secondary pulley speed of 150 r/min or less continues for 5 seconds.

- When the vehicle speed computed by CVT has dropped abruptly from 10 km/h (6.2 mph) or more to 5 km/h (3.1 mph) or less, and then the computing value keeps 5 km/h (3.1 mph) or less for 0.5 seconds continuously.

MONITOR EXECUTION

- transmission range: D

- Throttle valve opening: 1/8 or more

- Voltage of battery: 10 volts or more.

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0705: Malfunction of transmission range switch

- P0712, P0713: Malfunction of the transmission fluid temperature sensor

- P0715: Malfunction of primary pulley speed sensor

- P0725: Malfunction of engine speed

- P0740: Malfunction of lockup solenoid valve

- P0745: Malfunction of line pressure solenoid valve

- P0840: Malfunction of secondary pressure sensor

- P1723: Abnormality in speed sensor system function

- P1777: Malfunction of stepper motor

- U0001: Malfunction of CAN communication circuit

Sensor (The sensor below is determined to be normal)

- Transmission range switch

- Transmission fluid temperature sensor

- Primary pulley speed sensor

- Secondary pressure sensor

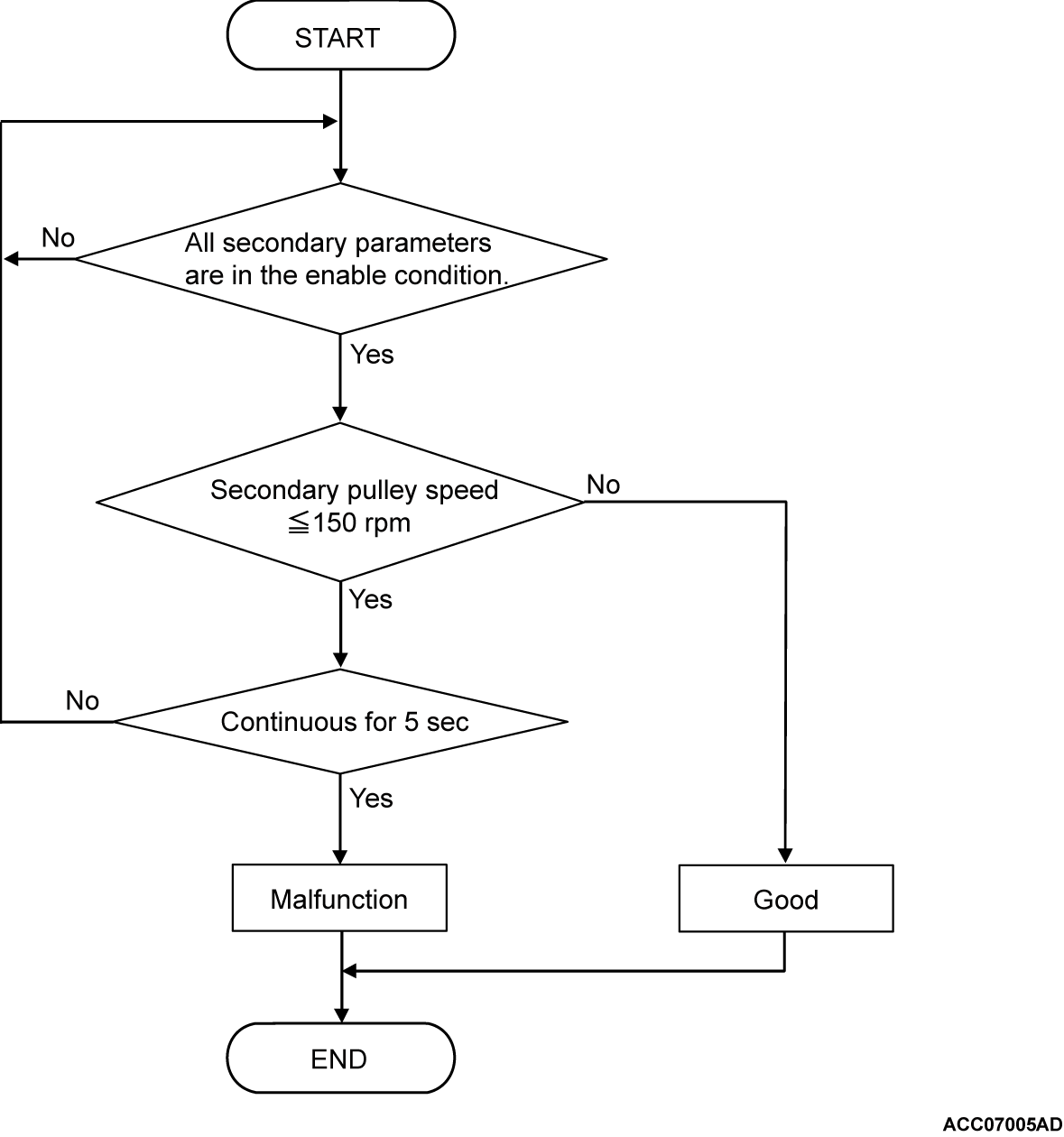

DTC SET CONDITIONS

Check Conditions

- Transmission range switch position: D.

- Throttle position sensor voltage: 1.37 volts or more.

- Primary pulley speed: 1,000 r/min or more.

- Secondary pulley speed at 10 millisecond before: 500 r/min or more.

- Voltage of battery: 9 volts or more.

- Voltage of battery: 16 volts or less.

Judgment Criteria

- Secondary pulley speed [primary pulley speed: 1,000 r/min or more]: 150 r/min or less. (5 seconds)

- Secondary pulley speed [secondary speed at 10 millisecond before: 500 r/min or more]: 260 r/min or less. (0.5 second)

OBD-II DRIVE CYCLE PATTERN

Transmission range: D (Drive the vehicle for 10 seconds or more while the accelerator opening angle is 20% or more)

PROBABLE CAUSES

- Malfunction of secondary pulley speed sensor

- Damaged wiring harness and connectors

- Malfunction of TCM

DIAGNOSIS

STEP 1. Scan tool data list

Item 2: Secondary speed sensor signal (Refer to Data List Reference Table  .)

.) Intermittent malfunction

Intermittent malfunction

.)

.)Is the check result normal?

Intermittent malfunction

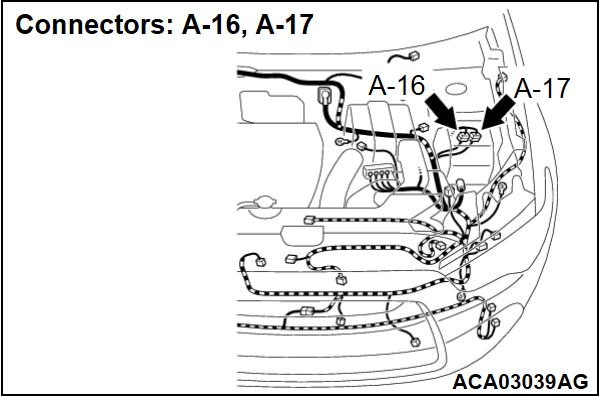

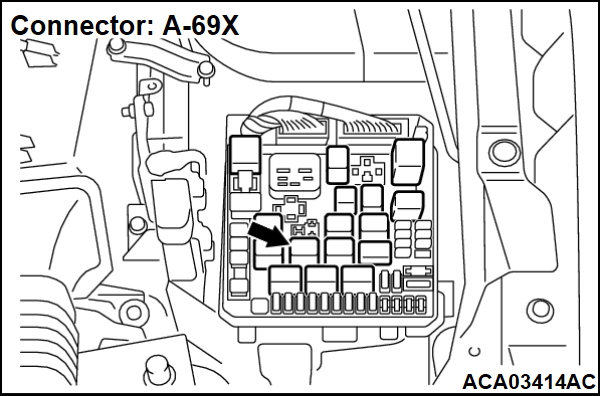

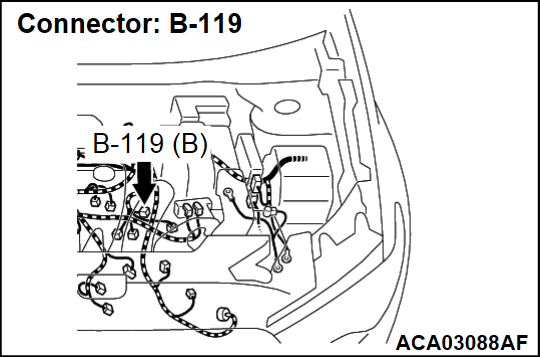

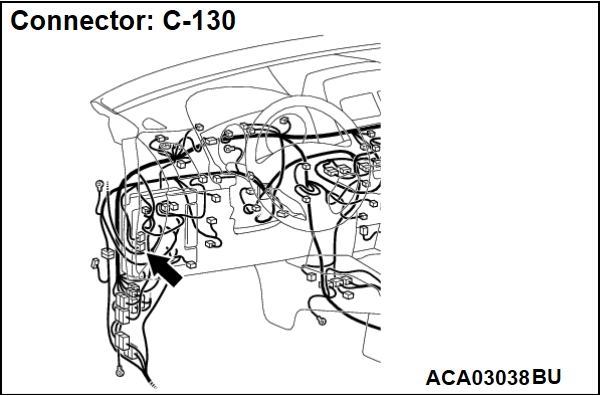

Intermittent malfunctionSTEP 2. Check the following connector:

- C-130 TCM connector

- B-119 Secondary pulley speed sensor connector

- A-16, A-17 Intermediate connector

Check the terminals for a contact status problem and internal short circuit.

Is the check result normal?

Repair the defective connector.

Repair the defective connector.STEP 3. Check for open circuit in the wiring harness between the secondary pulley speed sensor connector and the TCM connector.

Between B-119 secondary pulley speed sensor connector (terminal No.3) and C-130 TCM connector (terminal No.48) Repair the wiring harness.

Repair the wiring harness.

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.STEP 4. Check for open circuit and short to ground in the wiring harness between the secondary pulley speed sensor connector and the TCM connector

Between B-119 secondary pulley speed sensor connector (terminal No.2) and C-130 TCM connector (terminal No.36) Repair the wiring harness.

Repair the wiring harness.

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.STEP 5. Check for open circuit in the wiring harness between the CVT control relay and the secondary pulley speed sensor connector.

Between A-69X CVT control relay (terminal No.3) and B-119 secondary pulley speed sensor connector (terminal No.1) Repair the wiring harness.

Repair the wiring harness.

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.STEP 6. Secondary pulley speed sensor check

Visually check the tip of the sensor for foreign materials or damage. Repair.

Repair.

Is the check result normal?

Repair.

Repair.STEP 7. Diagnostic trouble code recheck after replacing the secondary pulley speed sensor

Is the check result normal?

The procedure is complete.

The procedure is complete. Replace TCM.

Replace TCM.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)