Required Special Tool:

MB991502: Scan Tool (MUT-II)

CAUTION: To prevent damage to scan tool MB991502, always turn the ignition switch to "LOCK" (OFF) position before connecting or disconnecting scan tool MB991502.

In this procedure, scan tool MB991502 should be used in the metric mode (showing the value in kPa). If not, set scan tool MB991502 by selecting the "System Setup" at the main menu.

STEP 1. Evaporative Emission System Monitor Test using scan tool MB991502.

CAUTION: With this monitor, the PCM automatically increases the engine speed to 1,600 r/min or more. Check that the transmission is set to "N" or "P."

(1)Turn the ignition switch to "ON" position.

(2)Erase the DTCs using the scan tool MB991502.

(3)Check that the fuel cap is securely closed. (Tighten until three clicks are heard.)

(4)Start the engine.

(5)Select "System Test," and press the "YES" key.

(6)Select "Evap Leak Mon," and press the "YES" key.

(7)During the monitor, keep the accelerator pedal at the idling position.

NOTE: If the engine speed does not reach 2,000 r/min during the monitor test, adjustment of the Speed Adjusting Screw may be needed. Refer to

(8)Keep the engine speed and engine load within the specified range. When the monitor test starts, the "In Progress" item on the scan tool MB991502 will change from "NO" to "YES."

(9)The message "Evap Leak Mon. Completed Test Passed" displays when the test has been completed without malfunction. The evaporative emission system is working properly at this time. Explain to customer that improperly tightened fuel cap can cause MIL to turn on, and return the vehicle.

(10)The message "Evap Leak Mon. Completed. Test Failed and DTC's Set" displays when a malfunction has been detected during the monitor test. Go to Step 2.

(11)The message "Evap Lead Mon. discontinued. Retest again from the first" is displayed when the monitor was discontinued for a certain reason (vehicle speed input from computer, engine speed and engine load deviating from specified range). Turn the ignition switch to "LOCK" (OFF) position once, and repeat the monitoring from the start.

NOTE: The fuel overflow limiter valve plunger opens and closes in sequence with the flapper door and fuel overflow limiter valve plunger.

When the fuel gun is inserted in the fuel filler neck and the flapper door is opened, the fuel overflow limiter valve plunger will close. (The fuel overflow limiter valve plunger will move to the top of the neck.)

When the fuel cap is closed, the fuel cap pushes the fuel overflow limiter valve plunger and the fuel overflow limiter valve plunger opens.

If the flapper door or fuel overflow limiter valve plunger does not operate correctly, the fuel overflow limiter valve plunger and fuel cap will interfere, and the fuel cap will not close completely. This can cause DTC P0442 to occur.

(2)Push the flapper with an ornament remover, etc., to activate the valve.

NOTE: The fuel overflow limiter valve plunger moves upward when the flapper is pushed.

(3)Tighten the fuel cap until three clicks are heard.

(5)Confirm that the distance from the end of the fuel tank filler neck to the end of the fuel overflow limiter valve plunger is 28 mm (1.1 inches) or more.

If the fuel overflow limiter valve plunger does not return completely [when less than 28 mm (1.1 inches)], replace the fuel tank filler neck, completely tighten the fuel cap and perform OBD-II drive cycle.

If the fuel overflow limiter valve plunger has completely returned [when 28 mm (1.1 inches) or more], completely tighten the fuel cap and go to Step 3.

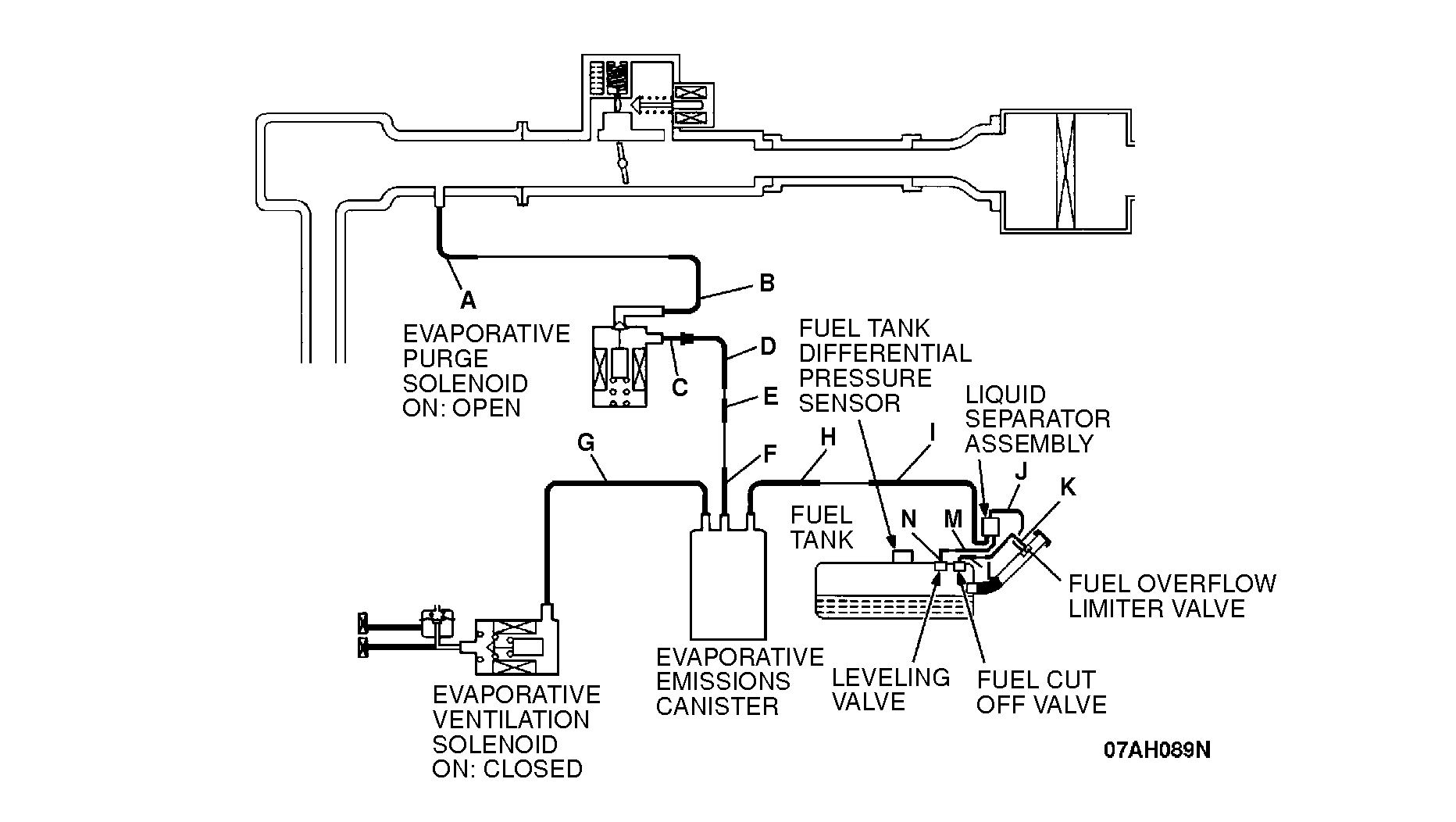

(1)Using locking pliers, pinch hose G between the canister and the evaporative emission ventilation solenoid.

(2)Confirm that the evaporative emission system pressure pump (Miller number 6872A) is operating properly. Perform the self-test as described in the manufacturer's instructions.

(4)Pressure test the system to determine whether any leaks are present.

NOTE: "Pressure test" in this procedure refers to the I/M240 Simulation Test (8 simple steps) described in the evaporative emission system pressure pump (Miller number 6872A) manufacturer's instructions located in the lid of the pump box.

If no leaks are indicated, go to Step 4.

If a leak is indicated, go to Step 5.

(1)Lower the evaporative emission canister assembly, turn the ignition switch to "ON" position, and disconnect hose G from the evaporative emission ventilation solenoid side.

(2)Connect a hand vacuum pump to the nipple of the evaporative emission ventilation solenoid from which the hose has been disconnected.

(3)Drive the evaporative emission ventilation solenoid with the scan tool MB991502 actuator test, and confirm that the vacuum does not fluctuate when vacuum is applied with the hand vacuum pump.

If the evaporative emission ventilation solenoid operates correctly and the applied vacuum does not fluctuate, go to Step 1.

If the evaporative emission ventilation solenoid operates correctly, but the vacuum is not maintained, replace the evaporative emission ventilation solenoid, and then go to Step 1.

If the evaporative emission ventilation solenoid does not operate, refer to the evaporative emission ventilation solenoid trouble code DTC P0446.

(1)Using locking pliers, pinch hose F between the canister and purge pipe.

(2)Perform the pressure test again.

If no leaks are indicated, go to Step 6.

If a leak is indicated, go to Step 8.

Perform leakage test with a hand vacuum pump on each hose from hose C to hose E.

If the location of the leak is pinpointed, replace that hose, and go to Step 1.

If the location of the leak cannot be pinpointed, go to Step 7.

(1)Connect a hand vacuum pump to the vent nipple of the evaporative emission canister.

(2)Plug the other two nipples or loop a hose between the other nipples.

(3)Apply a vacuum with the hand vacuum pump, and confirm that the applied vacuum does not fluctuate.

If the vacuum does not fluctuate, go to Step 1.

If the applied vacuum fluctuates, replace the evaporative emission canister and go to Step 1.

Perform leakage test with a hand vacuum pump on each hose from hose J and hose K.

If the location of the leak is pinpointed, replace that hose, and go to Step 1.

If the location of the leak cannot be pinpointed, go to Step 9.

(1)Remove the fuel tank. (Refer to GROUP 13F, Fuel Tank)

(2)Perform a leakage test with a hand vacuum pump on each hose from hose L M and N.

If the location of the leak is pinpointed, replace that hose and install the fuel tank. Then go to Step 1.

If the location of the leak cannot be pinpointed, go to Step 10.

(1)Visually check for cracks and leaks, etc.

NOTE: Carefully check the fuel pump assembly and the inner pressure sensor installation section in the fuel tank.

![[Previous]](../../../BUTTONS/fprev.png)

![[Next]](../../../BUTTONS/fnext.png)