DTC P1F0D: BATT.cooling EVAP.TEMP SNS.low

DTC P1F0E: BATT.cooling EVAP.TEMP SNS.high

DTC P1F0E: BATT.cooling EVAP.TEMP SNS.high

| caution | Whenever ECU is replaced, ensure that the CAN bus lines are normal. |

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

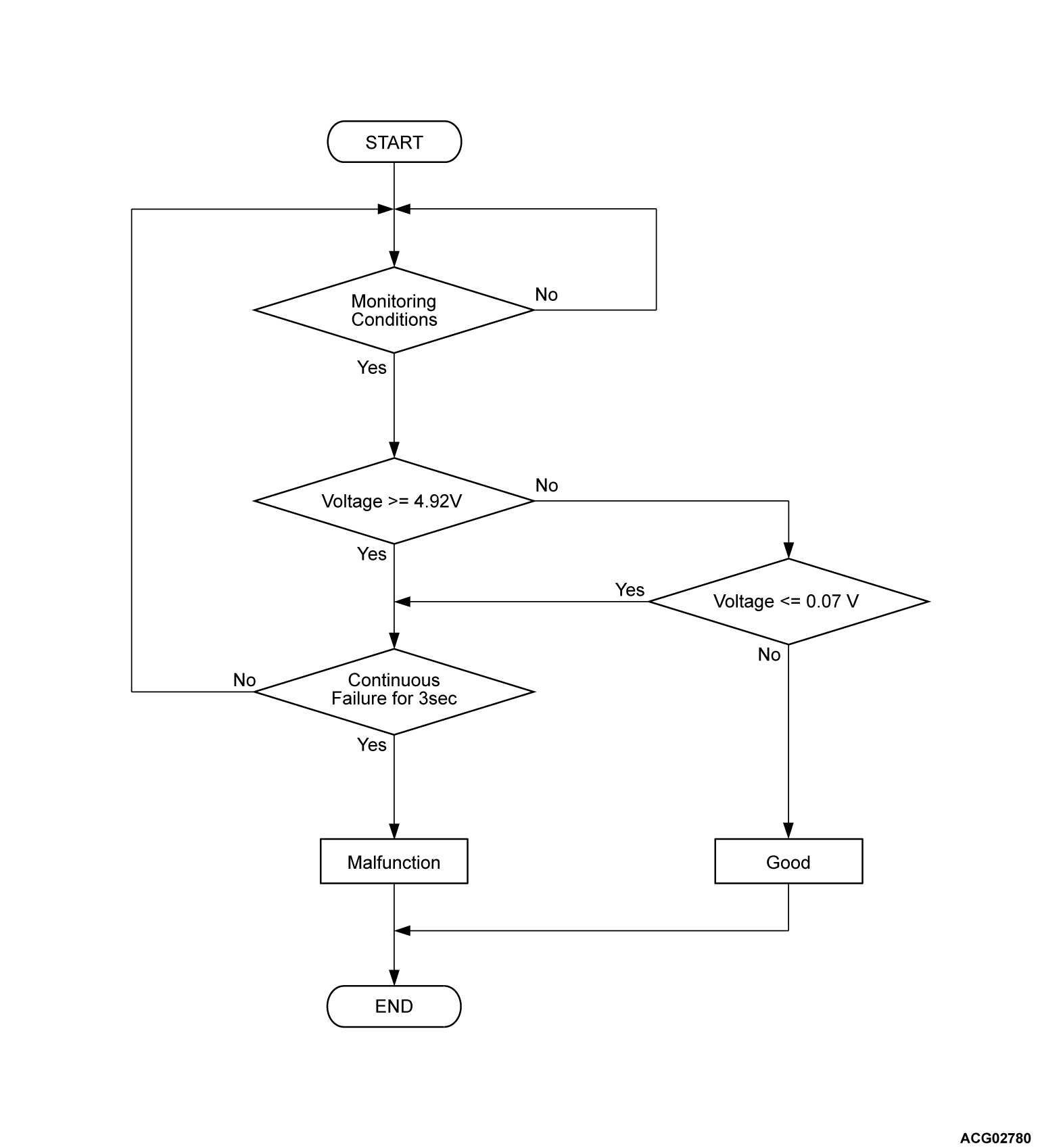

DTC SET CONDITIONS

Check Conditions

- The A/C compressor assembly power supply voltage is between 10 and 16 volts.

Judgment Criterion <DTC P1F0D>

- Change the battery cooling evaporator temperature sensor voltage is more than 0.07 volt [196°C (385°F)] for 3 seconds.

Check Conditions <DTC P1F0E>

- Change the battery cooling evaporator temperature sensor voltage is more than 4.92 volts [-55°C (67°F)] for 3 seconds.

PROBABLE CAUSES

- Malfunction of the CAN bus

- Malfunction of the heater controller assembly (A/C-ECU)

- Malfunction of the PHEV-ECU.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Scan tool (M.U.T.-IIISE) other system DTC [heater controller assembly (A/C-ECU)] (Refer to  ).

).

).

).Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)