DTC P1F70, P1F71, P1F72, P1F73, P1F74, P1F75, P1F76, P1F77, P1F7C, P1F7D, P1F7E, P1F7F, P1F80, P1F81, P1F82, P1F83, P1F88, P1F89, P1F8A, P1F8B, P1F8C, P1F8D, P1F8E, P1F8F, P1F94, P1F95, P1F96, P1F97, P1F98, P1F99, P1F9A, P1F9B, P1FA0, P1FA1, P1FA2, P1FA3, P1FA4, P1FA5, P1FA6, P1FA7, P1FB8, P1FB9, P1FBA, P1FBB, P1FBC, P1FBD, P1FBE, P1FBF, P1FC4, P1FC5, P1FC6, P1FC7, P1FC8, P1FC9, P1FCA, P1FCB, P1FD0, P1FD1, P1FD2, P1FD3, P1FD4, P1FD5, P1FD6, P1FD7, P1FDC, P1FDD, P1FDE, P1FDF, P1FE0, P1FE1, P1FE2, P1FE3, P1FE8, P1FE9, P1FEA, P1FEB, P1FEC, P1FED, P1FEE, P1FEF: Cell Battery Performance

DESCRIPTIONS OF MONITOR METHODS

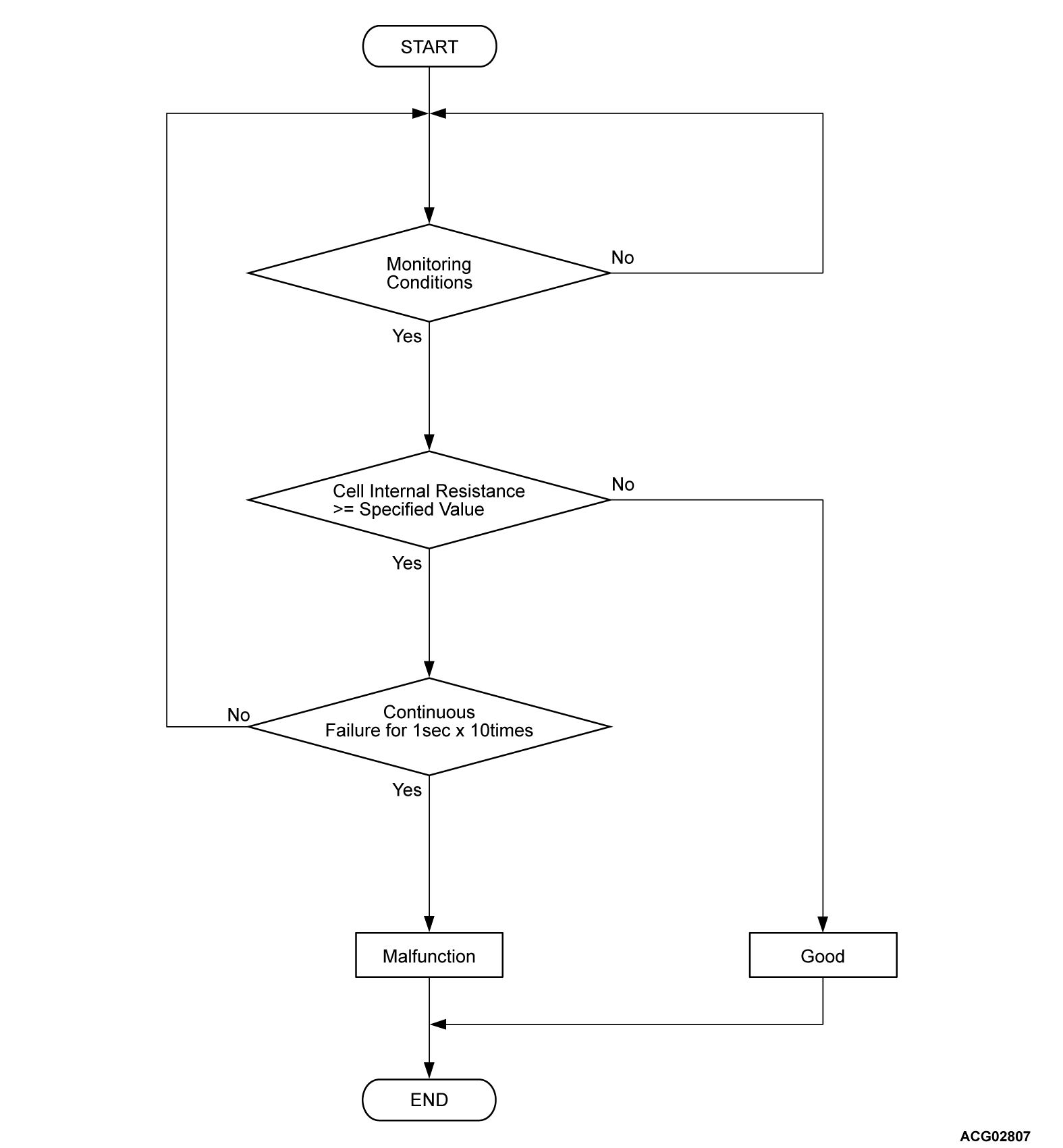

- Battery deterioration can be determined based on cell internal resistance.

- Cell internal resistance is calculated from cell voltage variation and cell current variation.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Battery CAN monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- BMU (SUB) power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is more than 2 seconds.

- Main drive lithium-ion battery current is more than 30 amperes.

- The main drive lithium-ion battery minimum temperature is more than 21°F (-6°C).

- Main drive lithium-ion battery energy level is 20 % to 90 %.

Judgment Criterion

- The state with the cell internal resistance being the specified value or more for 1 second without interruption is detected 10 times.

FAIL-SAFE AND BACKUP FUNCTION

- Not available

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)