DTC P1EF6: PTC Heater Relay(1) Stuck OFF

| caution | Before replacing the ECU, ensure that the communication circuit is normal. |

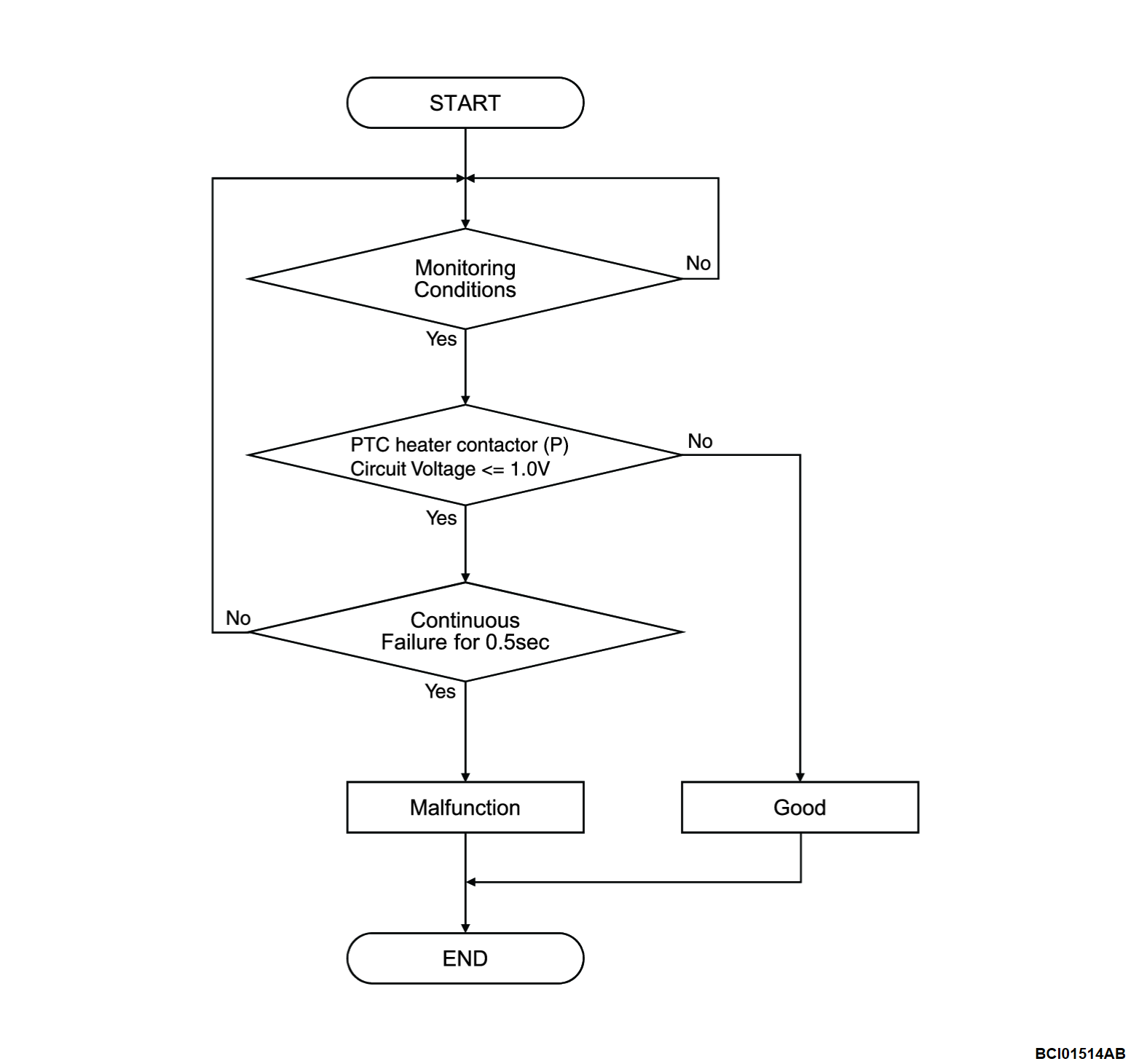

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Battery management unit (BMU) power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is more than 1 seconds.

- PTC heater contactor (P) drive relay ON.

Judgment Criterion

- The state of the PTC heater contactor (P) circuit voltage is less than 1.0 volt continues for 0.5 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Not available

PROBABLE CAUSES

- The main drive lithium-ion battery PTC heater contactor (P) drive relay is failed

- Open or short to ground system of main drive lithium-ion battery PTC heater contactor drive relay (P) circuit; poor contact of connector.

- The battery management unit (BMU) is failed.

DIAGNOSIS

Required Special Tools

- MB991658: Test harness

STEP 1. Check the main drive lithium-ion battery PTC heater contactor (P) drive relay

STEP 2. Measure the voltage at main drive lithium-ion battery PTC heater contactor (P) drive relay connector (terminal No.3).

(1) Remove main drive lithium-ion battery PTC heater contactor (P) drive relay, and measure at the wiring harness side.

(2) Turn on the power supply mode of the electric motor switch.

(3) Check the voltage between the main drive lithium-ion battery PTC heater contactor (P) drive relay connector (terminal No.3) and body ground.

OK: Battery voltage

Is the check result normal?

STEP 3. Measure the resistance between the main drive lithium-ion battery PTC heater contactor (P) drive relay connector and the main drive lithium-ion battery connector.

(1) Disconnect the D-34 main drive lithium-ion battery connector and main drive lithium-ion battery PTC heater contactor (P) drive relay, and measure at the wiring harness side.

(2) Measure the resistance between the following terminals.

Check the resistance between the D-34 main drive lithium-ion battery connector (terminal No.2) and body ground.

OK: No continuity

(3) Check the resistance between the D-34 main drive lithium-ion battery connector (terminal No.2) and main drive lithium-ion battery PTC heater contactor (P) drive relay connector (terminal No.4).

OK: Continuity exists (2 Ω or less)

Is the check result normal?

Repair the connector(s) or wiring harness.

Repair the connector(s) or wiring harness.STEP 4. Measure the resistance between the BMU connector and the main drive lithium-ion battery connector.

(1) Disconnect the D-34 main drive lithium-ion battery connector and BMU connector, and measure at the wiring harness side.

(2) Measure the resistance between the following terminals.

- Check the resistance between the D-34 main drive lithium-ion battery connector (terminal No.2) and BMU connector (PBIN terminal).

OK: Continuity exists (2 Ω or less)

Is the check result normal?

Repair the connector(s) or wiring harness.

Repair the connector(s) or wiring harness.STEP 5. Measure the resistance at the main drive lithium-ion battery connector.

(1) Disconnect the D-34 main drive lithium-ion battery connector, and measure at the main drive lithium-ion battery side.

(2) Check the resistance between the D-34 main drive lithium-ion battery connector (terminal No.2) and body ground.

OK: No continuity

Is the check result normal?

STEP 6. Using scan tool (M.U.T.-IIISE), check whether the DTC is set again.

Recheck if the DTC is set.

(1) Erase the DTC.

(2) Depress the brake pedal, and turn on the power supply mode of the electric motor switch (READY operation)*.

| note | *: When a DTC is set, you cannot make the READY (ready to drive) indicator illuminate by making the READY operation. |

(3) Check if the DTC is set.

Is the DTC set?

STEP 7. Using scan tool (M.U.T.-IIISE), check the data list <BMU>

Check the BMU's data list (Refer to  ).

).

).

).- Item No.438: BAT. heat initial judge. end flag

Is the value of data list "ON"?

STEP 8. Using scan tool (M.U.T.-IIISE), check whether the DTC is set again.

(1) Depress the brake pedal, and turn on the power supply mode of the electric motor switch (READY operation)*.

| note | *: When a DTC is set, you cannot make the READY (ready to drive) indicator illuminate by making the READY operation. |

(2) Select "BMU" from System select Screen of the scan tool (M.U.T.-IIISE).

(3) Select the "Special Function" from the BMU screen.

(4) Select the "Test" from the Special Function screen

(5) Select the "Battery heating system drive" from the Test screen.

| note | "Battery heating system drive" can be performed only once after the power supply mode of the electric motor switch is turned ON. |

(6) Check if the DTC is set.

Is the DTC set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)