DTC P0AA8: Leak Sensor Detection Circuit Open

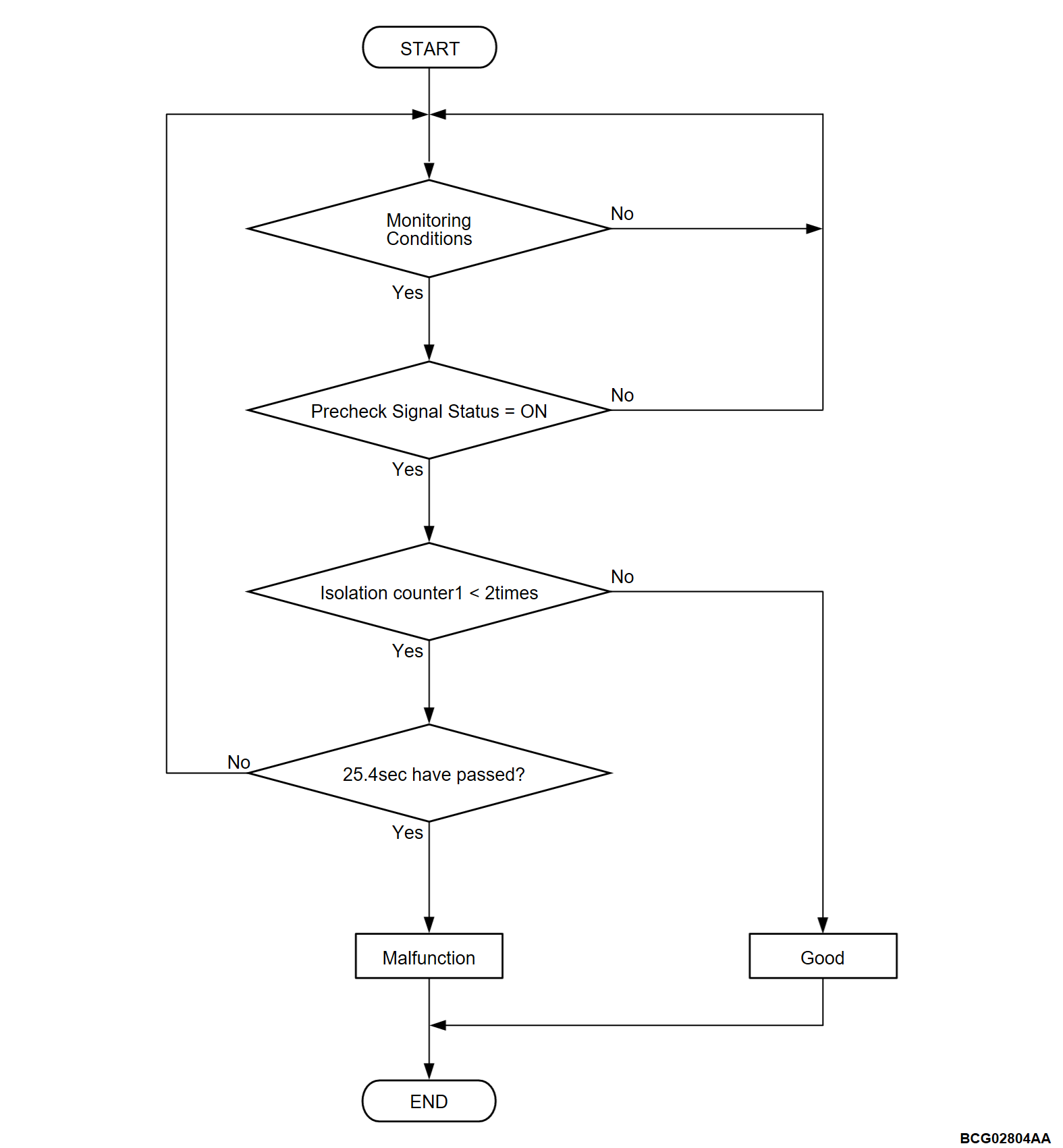

DESCRIPTIONS OF MONITOR METHODS

- The monitor executes immediately after hybrid system launch.

- Precheck circuit can simulate isolation state intentionally when "Precheck signal status is on".

- The monitor judges circuit malfunction when the monitor cannot detect the isolation state at "Precheck signal status is on".

- The monitor detects a malfunction by using "Isolation counter 1".

MONITOR EXECUTION

- Once per driving cycle

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- BMU (SUB) power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is more than 3.5 seconds.

- Precheck signal status is on.

Judgment Criterion

- Isolation counter 1 is less than 2 times for 25.4 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Not available

PROBABLE CAUSES

- Ground fault of high voltage system component.

- The main drive lithium-ion battery ground fault detector failed.

- Open circuits of main drive lithium-ion battery ground fault detector circuit, short circuits to ground, short circuits to power supply system or damage; poor contact of connector.

- The sub-battery management unit [BMU (SUB)] is failed.

DIAGNOSIS

Required Special Tools

- MB991658: Test harness

| danger | When high voltage system components are serviced, be sure to pull service plugs to shut down high voltage before servicing (Refer to  ). ). |

| danger | When pulling service plugs, wear the specified protective equipment (Refer to  ). ). |

STEP 1. Measure the resistance at main drive lithium-ion battery connector.

(1) Disconnect the D-34 main drive lithium-ion battery connector, and measure at the wiring harness side.

(2) Check the resistance between the D-34 main drive lithium-ion battery connector (terminal No.6) and body ground.

OK: Continuity exist (2 Ω or less)

Is the check result normal?

STEP 2. Check of open circuit in line between main drive lithium-ion battery connector and sub-battery management unit [BMU (SUB)] connector.

(2) Disconnect the sub-battery management unit [BMU (SUB)] connector, and measure at the wiring harness side.

(3) Check the resistance between the sub-battery management unit [BMU (SUB)] connector (LGND terminal) and D-34 main drive lithium-ion battery connector (terminal No.6).

OK: Continuity exists (2 Ω or less)

(4) Check the resistance between the sub-battery management unit [BMU (SUB)] connector (TP1 terminal) and sub-battery management unit [BMU (SUB)] connector (TP2 terminal). <High voltage>

OK: Continuity exists (2 Ω or less)

Is the check result normal

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)