DTC P1ADF: +B Line Voltage

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- EV-CAN monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

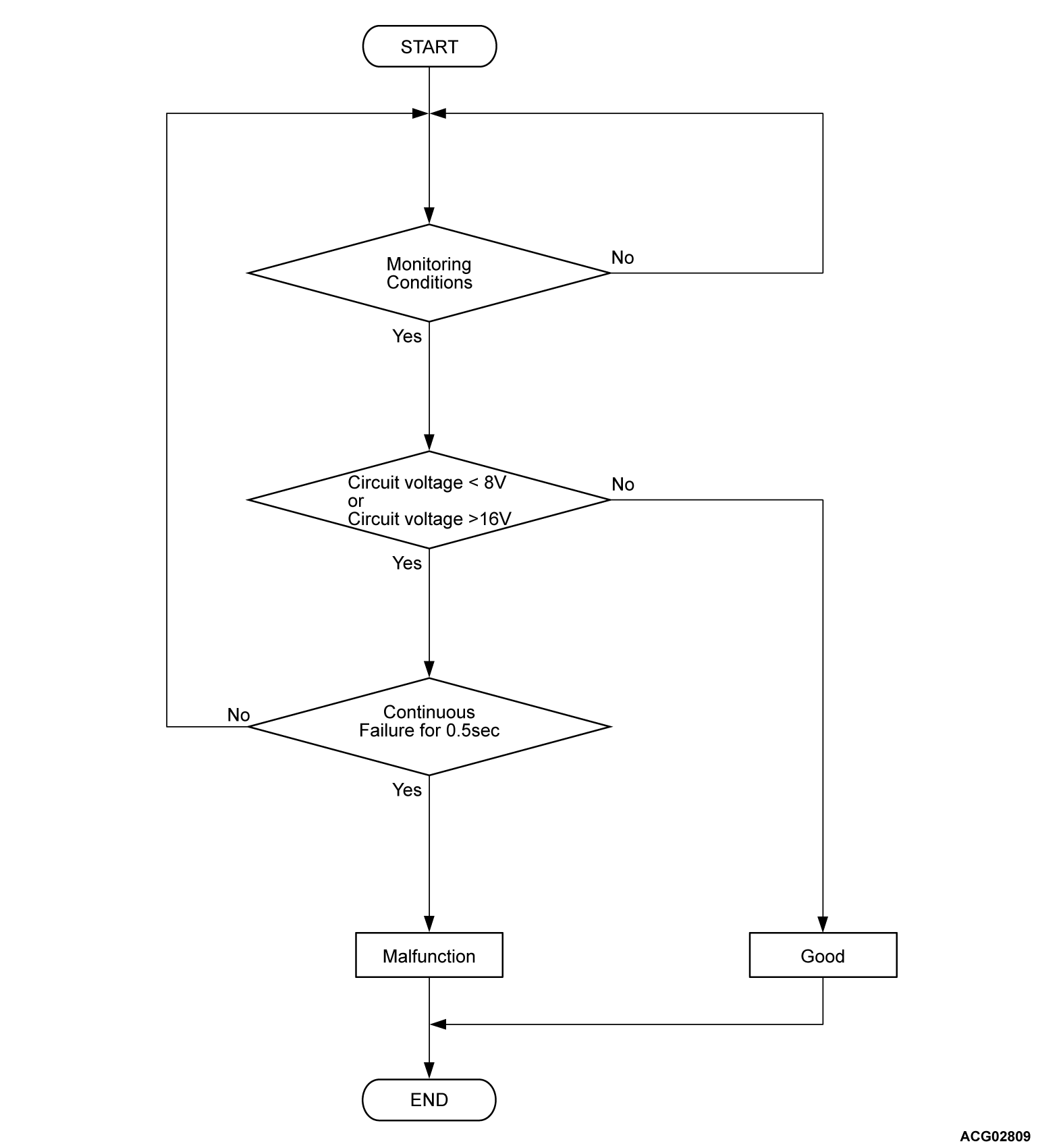

DTC SET CONDITIONS

Check Conditions

- BMU (SUB) power supply voltage is more than 6 volts.

- Time after above conditions satisfy is more than 1 second.

Judgment Criterion

- Change of the BMU (SUB) power supply voltage is less than 8 volts or more than 16 volts for 0.5 second.

FAIL-SAFE AND BACKUP FUNCTION

- Not available

PROBABLE CAUSES

- The 12V starter battery is failed.

- The installation of the 12V starter battery terminal is failed.

- Open circuits of BMU (SUB) power supply circuit, short circuits to ground or damage; poor contact of connector

- The sub-battery management unit [BMU (SUB)] is failed.

| note | When using the higher voltage from the outside of the vehicle than the voltage of the 12V starter battery. |

DIAGNOSIS

Required Special Tools

- MB991658: Test harness

STEP 1. Using scan tool (M.U.T.-IIISE), check whether the other DTC is set.

Check whether the PHEV-ECU set a DTC P0A09 which is related to the on board charger/DC-DC converter.

Is the DTC set?

STEP 2. 12V starter battery condition check

Check the installation status of the 12V starter battery terminal.

Is the check result normal?

STEP 3. Check 12V starter battery

Check 12V starter battery (Refer to GROUP 54A - 12V starter battery, On-vehicle Service, Battery Test  ).

).

).

).Is the check result normal?

STEP 4. Measure the voltage at main drive lithium-ion battery connector

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the voltage between the main drive lithium-ion battery connector [BMU (SUB) BAT line] and body ground.

OK: Battery voltage

Is the check result normal?

STEP 5. Measure the resistance at main drive lithium-ion battery connector [BMU (SUB) GND line].

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Check the resistance between the main drive lithium-ion battery connector [BMU (SUB) GND line] and body ground.

OK: Continuity (2 Ω or less)

Is the check result normal?

STEP 6. Measure the resistance at main drive lithium-ion battery connector.

(2) Disconnect the connector, and measure at the main drive lithium-ion battery side.

(3) Check the resistance BMU (SUB) BAT line between the main drive lithium-ion battery connector and sub-battery management unit [BMU (SUB)] connector.

(4) Check the resistance BMU (SUB) GND line between the main drive lithium-ion battery connector and sub-battery management unit [BMU (SUB)] connector.

OK: Continuity (2 Ω or less)

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)