DTC P0AF3: IGBT temperature sensor fails (range)

| danger |

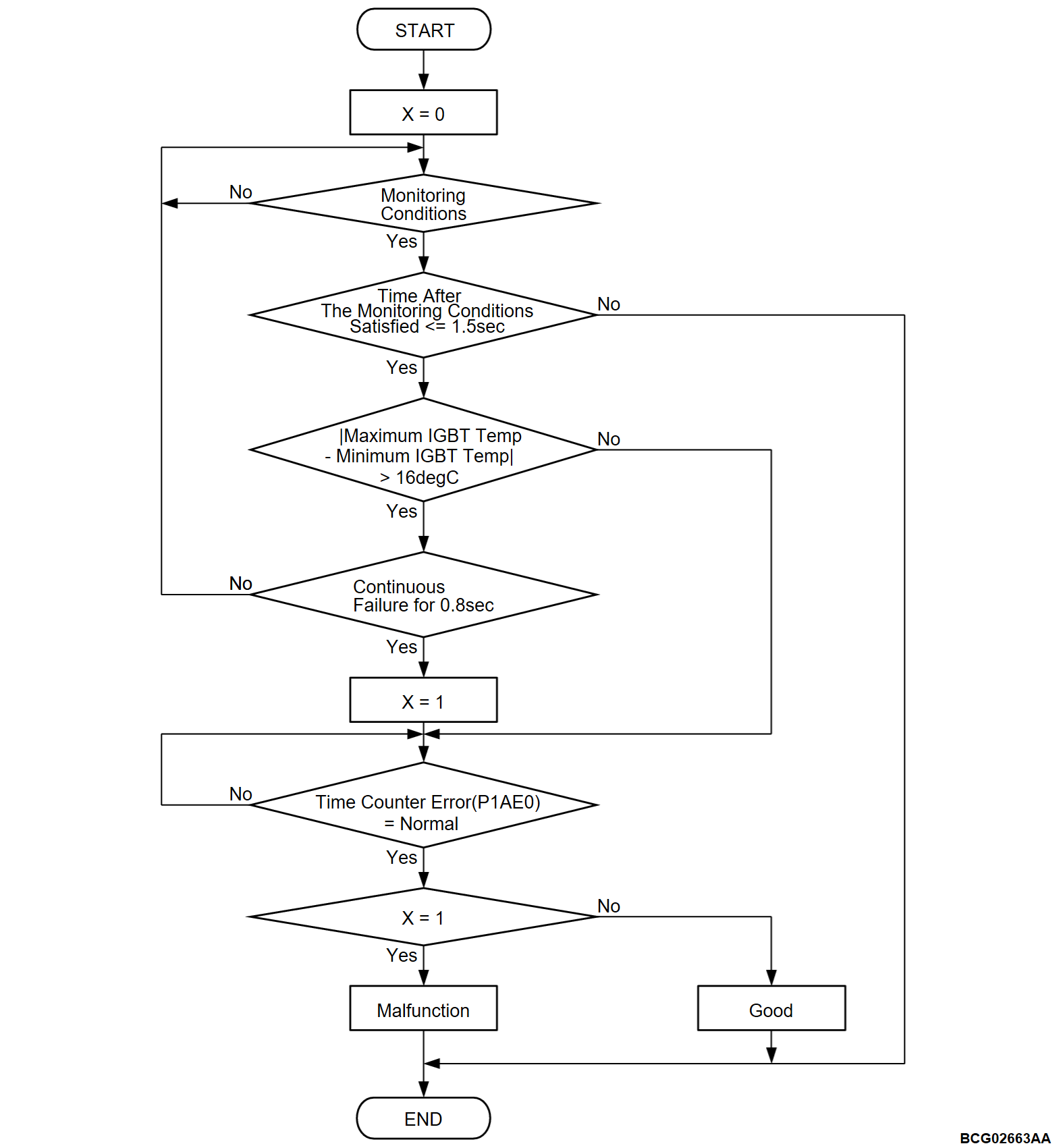

DESCRIPTIONS OF MONITOR METHODS

- A rationality monitor will be used to compare the temperature of each phase within one IGBT.

- The difference between minimum and maximum phase temperature within an IGBT is calculated.

MONITOR EXECUTION

- Once per driving cycle

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Non-volatile random access memory monitor

- EV-CAN monitor

- Battery energy control module (sub BMU) monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Power REMCU power supply voltage is 8 volts to 16 volts.

- Time after above conditions satisfy is less than 1.5 seconds.

- The soaking time is more than 300 seconds.

- The IGBT status of GCU is off (Shutdown).

Judgment Criterion

- The absolute value of the difference between the maximum IGBT temperature and minimum IGBT temperature remains 16°C (61°F) or more in 0.8 seconds.

note - Maximum IGBT temperature is the temperature of hottest phase between U-phase, V-phase and W-phase.

- Minimum IGBT temperature is the temperature of coldest phase between U-phase, V-phase and W-phase.

PROBABLE CAUSES

- Malfunction of the REMCU

- Malfunction of the rear motor high voltage circuit system

DIAGNOSIS

STEP 1. Check the high-voltage terminal.

| danger | Carry out the check on the high-voltage circuit while reading carefully the precautions on handling a high-voltage vehicle (Refer to  ). ). |

| danger | Wear the specified protection equipment during the check. |

(2) Check that the following cable is tightened to the specified torque.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)