DTC P0ADB: Main contactor P circuit low

DTC P0ADF: Main contactor N circuit low

DTC P0ADF: Main contactor N circuit low

| caution | Before replacing the ECU, ensure that the communication circuit is normal. |

DESCRIPTIONS OF MONITOR METHODS

- Contactor excitation circuit status is judged by voltage and current of an intelligent power device (IPD) in the PHEV-ECU.

- Each fail is judged under the following conditions.

- Main contactor (P) control circuit shorted low: Main contactor (P) control circuit active command on.

- Main contactor (N) control circuit shorted low: Main contactor (N) control circuit active command on.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions <DTC P0ADB>

- The PHEV-ECU power supply voltage is more than 9.0 volts.

- The main contactor (P) contactor activation command on.

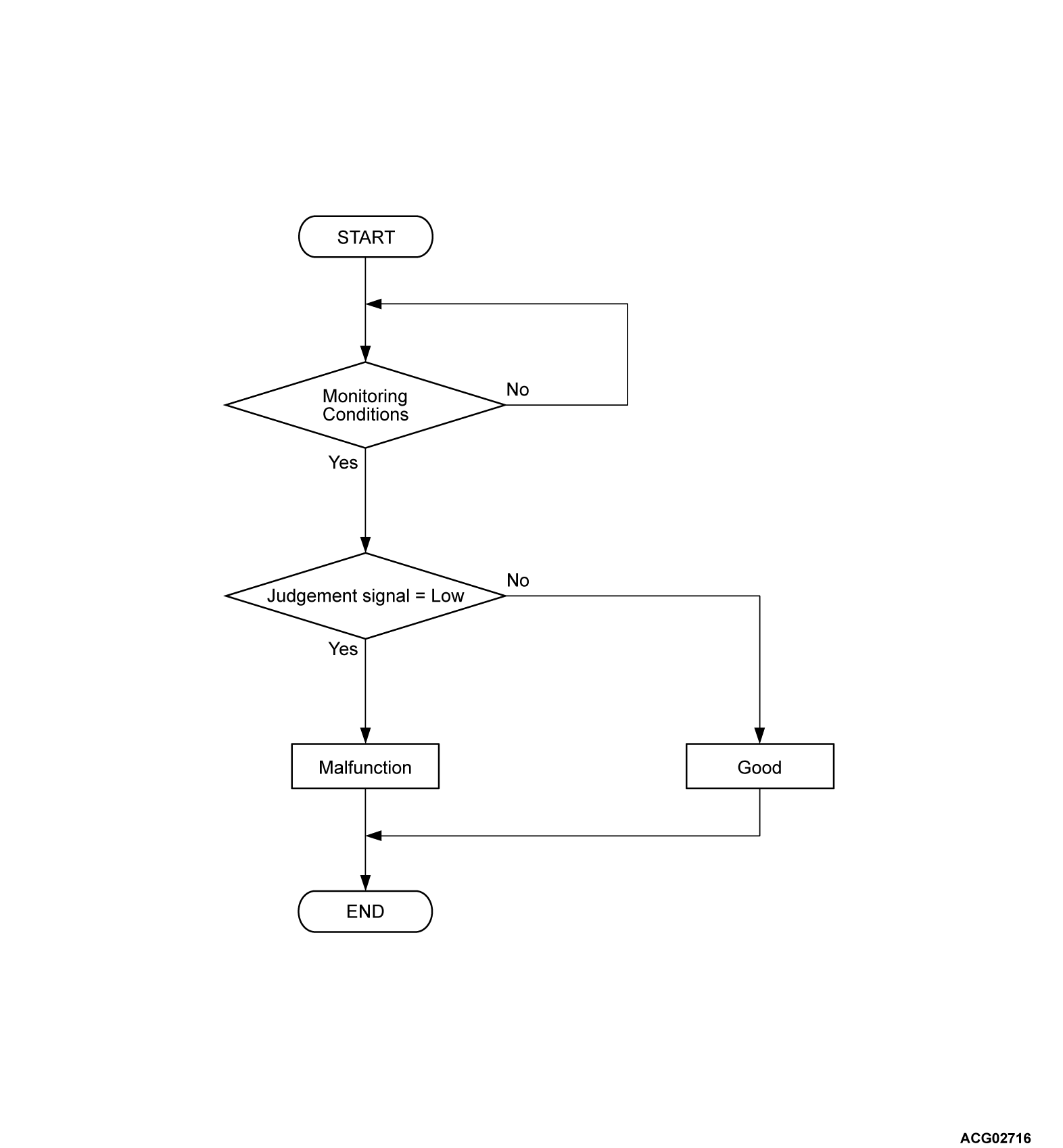

Judgment Criterion <DTC P0ADB>

- Judgment signal from intelligent power device (IPD) for main contactor (P) is low for immediately.

Check Conditions <DTC P0ADF>

- The PHEV-ECU power supply voltage is more than 9.0 volts.

- The main contactor (N) contactor activation command on.

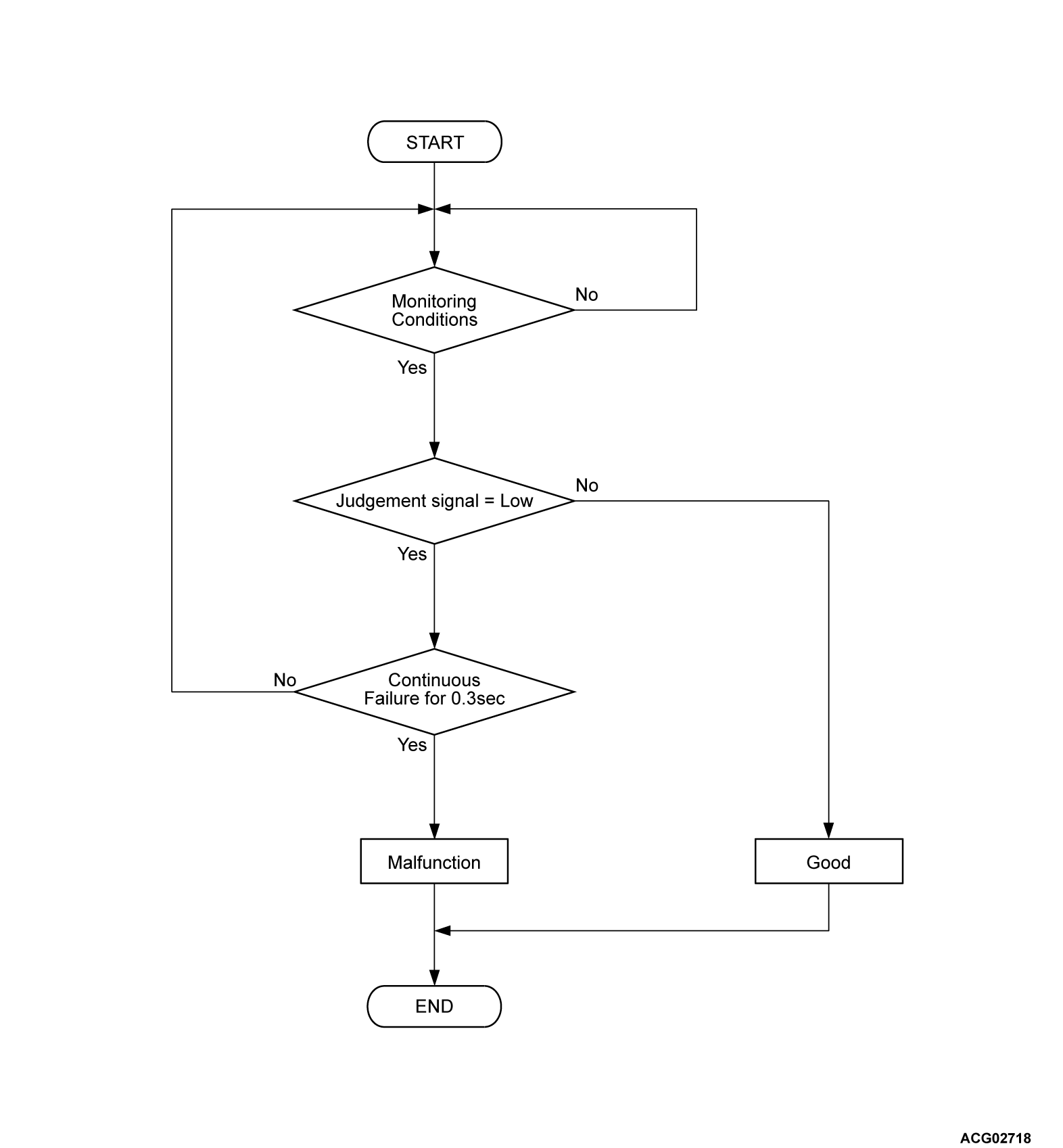

Judgment Criterion <DTC P0ADF>

- Judgment signal from intelligent power device (IPD) for main contactor (N) is low for 0.3 seconds.

PROBABLE CAUSES

- Damaged harness or connector.

- Malfunction of the main contactor (P) or (N).

- Malfunction of the PHEV-ECU.

DIAGNOSIS

Required Special Tools

- MB991223: Wiring harness set

- MB992006: Extra fine probe

STEP 1. Check the signal line for short to ground circuit (PHEV-ECU connector and main drive lithium-ion battery connector).

Check the wiring harness between PHEV-ECU connector (terminal CNT+, CNT-) and the main drive lithium-ion battery connector.

Is the check result normal?

STEP 2. Check the main drive lithium-ion battery main contactor (P) and (N) <On-vehicle check>.

Check resistance of main contactor (P) and (N) coil with harness connector (Refer to GROUP 54Dc - On-vehicle Service, Check on Coil Resistance of Contactor  ).

).

).

).Is the check result normal?

STEP 3. Check the main drive lithium-ion battery main contactor (P) and (N).

(1) Remove the main contactor (Refer to GROUP 54Dc - Main Drive Lithium-ion Battery Disassembly and Assembly, Rear JB Assembly, Rear JB Bus Bars (A, B, C, D, M, N, P and T), Contactor and Fuse Removal and Installation  ).

).

).

).(2) Check the internal resistance in the coil in the main contactors (P) and (N) (Refer to GROUP 54Dc - Main Drive Lithium-ion Battery Disassembly and Assembly, Contactor Check  ).

).

).

).Is the check result normal?

STEP 4. Check the signal line for short to ground circuit (main drive lithium-ion battery connector and main contactor).

- DTC P0ADB: Check the wiring harness between main drive lithium-ion battery connector and the main contactor (P) <CNT+ line>.

- DTC P0ADF: Check the wiring harness between main drive lithium-ion battery connector and the main contactor (N) <CNT- line>.

Is the check result normal?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)