DTC P084A: Abnormality in Primary Pressure Sensor Function

DIAGNOSTIC FUNCTION

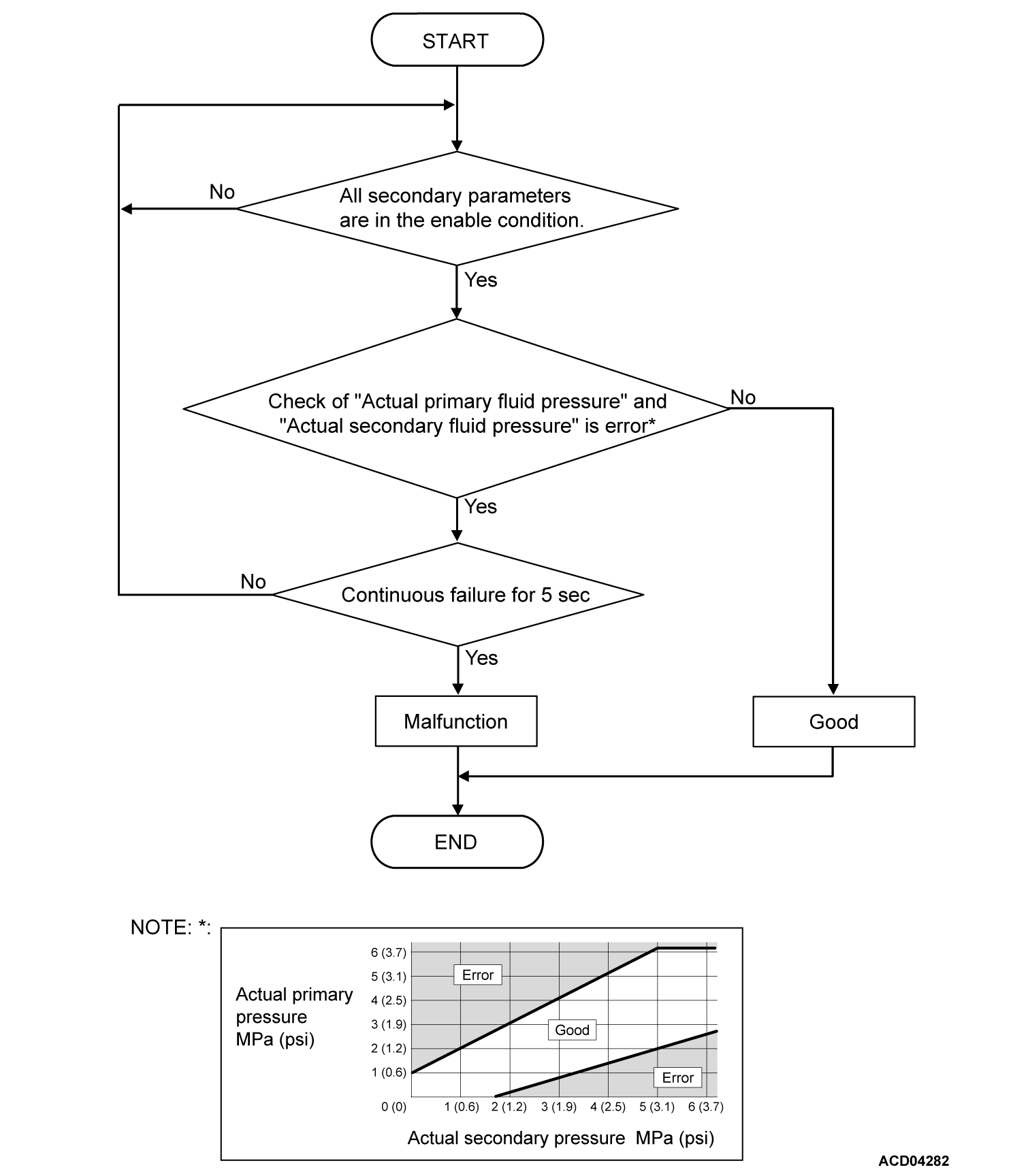

The TCM determines that the system is defective when the primary pressure sensor output voltage is outside the predetermined value range.

DESCRIPTIONS OF MONITOR METHODS

All the conditions listed below remain for 5 seconds.

- The pulley ratio is 0.5 or more, 1.0 or less.

- The primary pulley speed is 300 r/min or more.

- The secondary pulley speed is 250 r/min or more.

- Target shifting speed is 0.1/sec or less.

- The primary pressure is outside the predetermined pressure range.

MONITOR EXECUTION

- Voltage of battery: 10 volts or more.

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0966, P0967: Malfunction of secondary pressure solenoid valve

- P0970, P0971: Malfunction of primary pressure solenoid valve

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Voltage of battery: 10 volts or more.

- Primary pulley speed: 300 r/min or more.

- Secondary pulley speed: 250 r/min or more.

- Pulley ratio: More than 0.5, less than 1.0.

Judgment Criteria

- Check of "Actual primary pressure" and "Actual secondary pressure" is error. (5 seconds)

OBD-II DRIVE CYCLE PATTERN

Ignition switch: ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of valve body assembly (Faulty primary pressure sensor, secondary pressure sensor)

- Damaged wiring harness and connectors

- Malfunction of the CVT assembly

DIAGNOSIS

STEP 1. M.U.T.-III diagnostic trouble code

Is diagnostic trouble code No. P0842, P0843, P0847 or P0848 set?

Carry out the appropriate troubleshooting.

Carry out the appropriate troubleshooting.STEP 2. Symptom recheck after erasing diagnostic trouble code

Turn the ignition switch to the "LOCK" (OFF) position, and wait for one minute. Then, drive the vehicle for a while and check again. Replace the CVT assembly.

Replace the CVT assembly.

Is the diagnostic trouble code set?

Replace the CVT assembly.

Replace the CVT assembly.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)