DTC P0729, P0732, P0733, P0734, P0735: 6th, 2nd, 3rd, 4th, 5th Gear Ratio

DESCRIPTIONS OF MONITOR METHODS <DTC P0729>

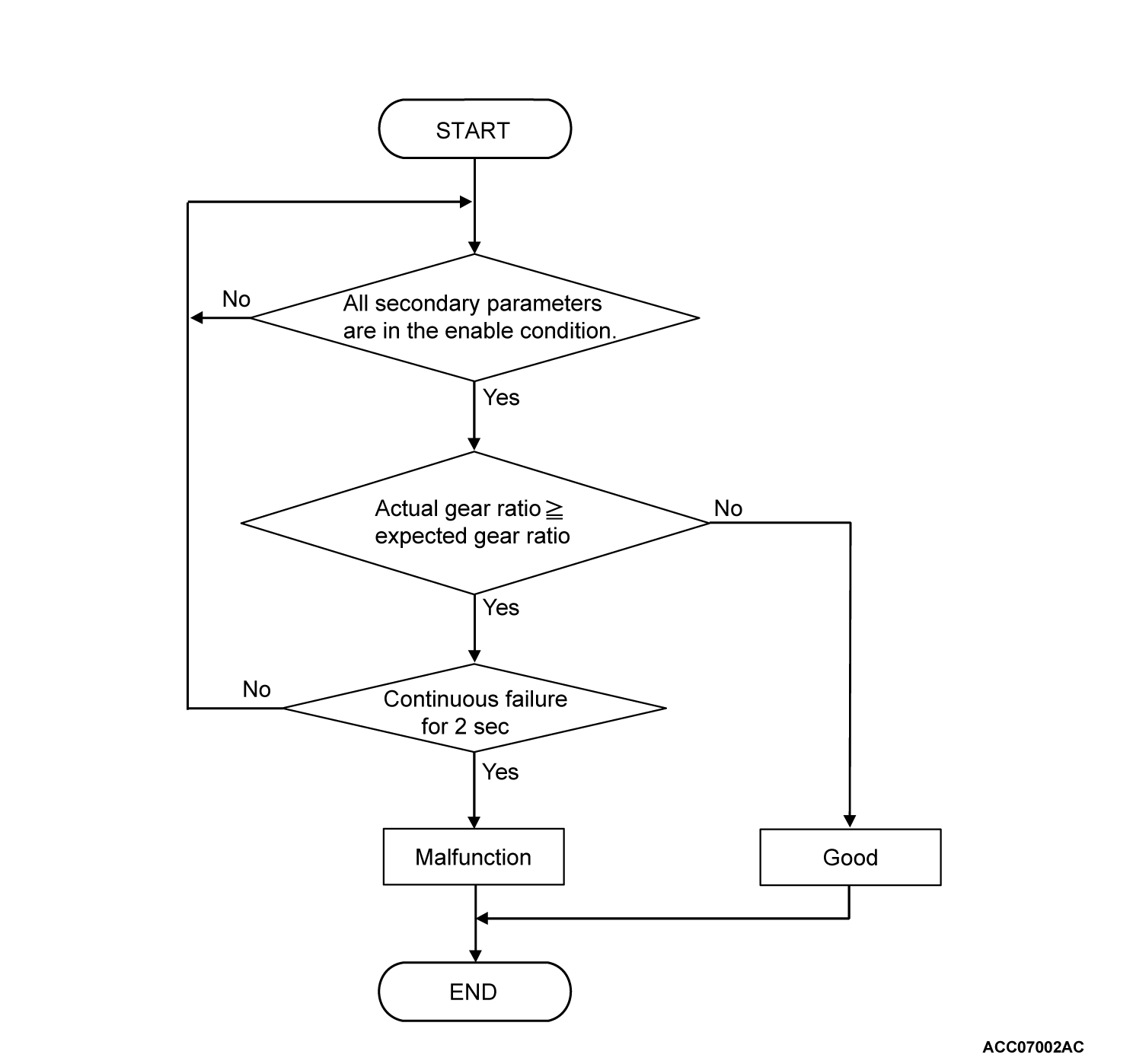

After 6th gear is achieved for 2 seconds, the engine runup*1 is detected for 2 seconds.

*1: The actual gear ratio deviates from the target gear ratio to the high engine (turbine) speed.

MONITOR EXECUTION <DTC P0729>

- 6th gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR) <DTC P0729>

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0846: 2-6 brake pressure switch system

- P0876: High clutch pressure switch system

- P0988: Low-reverse brake pressure switch system

Sensor (The sensor below is determined to be normal)

- Input shaft speed sensor

- Output shaft speed sensor

- Transmission range switch

- Lock-up and low-reverse brake linear solenoid

- Low clutch linear solenoid

- 2-6 brake linear solenoid

- 3-5 reverse clutch linear solenoid

- High clutch linear solenoid

- Low clutch shift solenoid

- Low-reverse brake shift solenoid

- Engine revolution signal

- CAN communication

DTC SET CONDITIONS <DTC P0729>

Check Conditions

- Shift stage: 6th gear.

- Time after shift changing finish: 2 seconds or more.

Judgment Criteria

- Gear ratio: 0.771 or more. (2 seconds)

OBD-II DRIVE CYCLE PATTERN <DTC P0729>

6th gear driving for 5 seconds or more

DESCRIPTIONS OF MONITOR METHODS <DTC P0732>

After 2nd gear is achieved for 2 seconds, the engine runup*1 is detected for 2 seconds.

*1: The actual gear ratio deviates from the target gear ratio to the high engine (turbine) speed.

MONITOR EXECUTION <DTC P0732>

- 2nd gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR) <DTC P0732>

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0846: 2-6 brake pressure switch system

- P0876: High clutch pressure switch system

- P0988: Low-reverse brake pressure switch system

Sensor (The sensor below is determined to be normal)

- Input shaft speed sensor

- Output shaft speed sensor

- Transmission range switch

- Lock-up and low-reverse brake linear solenoid

- Low clutch linear solenoid

- 2-6 brake linear solenoid

- 3-5 reverse clutch linear solenoid

- High clutch linear solenoid

- Low clutch shift solenoid

- Low-reverse brake shift solenoid

- Engine revolution signal

- CAN communication

DTC SET CONDITIONS <DTC P0732>

Check Conditions

- Shift stage: 2nd gear.

- Time after shift changing finish: 2 seconds or more.

Judgment Criteria

- Gear ratio: 3.302 or more. (2 seconds)

OBD-II DRIVE CYCLE PATTERN <DTC P0732>

2nd gear driving for 5 seconds or more

DESCRIPTIONS OF MONITOR METHODS <DTC P0733>

After 3rd gear is achieved for 2 seconds, the engine runup*1 is detected for 2 seconds.

*1: The actual gear ratio deviates from the target gear ratio to the high engine (turbine) speed.

MONITOR EXECUTION <DTC P0733>

- 3rd gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR) <DTC P0733>

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0846: 2-6 brake pressure switch system

- P0876: High clutch pressure switch system

- P0988: Low-reverse brake pressure switch system

Sensor (The sensor below is determined to be normal)

- Input shaft speed sensor

- Output shaft speed sensor

- Transmission range switch

- Lock-up and low-reverse brake linear solenoid

- Low clutch linear solenoid

- 2-6 brake linear solenoid

- 3-5 reverse clutch linear solenoid

- High clutch linear solenoid

- Low clutch shift solenoid

- Low-reverse brake shift solenoid

- Engine revolution signal

- CAN communication

DTC SET CONDITIONS <DTC P0733>

Check Conditions

- Shift stage: 3rd gear.

- Time after shift changing finish: 2 seconds or more.

Judgment Criteria

- Gear ratio: 1.994 or more. (2 seconds)

OBD-II DRIVE CYCLE PATTERN <DTC P0733>

3rd gear driving for 5 seconds or more

DESCRIPTIONS OF MONITOR METHODS <DTC P0734>

After 4th gear is achieved for 2 seconds, the engine runup*1 is detected for 2 seconds.

*1: The actual gear ratio deviates from the target gear ratio to the high engine (turbine) speed.

MONITOR EXECUTION <DTC P0734>

- 4th gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR) <DTC P0734>

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0846: 2-6 brake pressure switch system

- P0876: High clutch pressure switch system

- P0988: Low-reverse brake pressure switch system

Sensor (The sensor below is determined to be normal)

- Input shaft speed sensor

- Output shaft speed sensor

- Transmission range switch

- Lock-up and low-reverse brake linear solenoid

- Low clutch linear solenoid

- 2-6 brake linear solenoid

- 3-5 reverse clutch linear solenoid

- High clutch linear solenoid

- Low clutch shift solenoid

- Low-reverse brake shift solenoid

- Engine revolution signal

- CAN communication

DTC SET CONDITIONS <DTC P0734>

Check Conditions

- Shift stage: 4th gear.

- Time after shift changing finish: 2 seconds or more.

Judgment Criteria

- Gear ratio: 1.372 or more. (2 seconds)

OBD-II DRIVE CYCLE PATTERN <DTC P0734>

4th gear driving for 5 seconds or more

DESCRIPTIONS OF MONITOR METHODS <DTC P0735>

After 5th gear is achieved for 2 seconds, the engine runup*1 is detected for 2 seconds.

*1: The actual gear ratio deviates from the target gear ratio to the high engine (turbine) speed.

MONITOR EXECUTION <DTC P0735>

- 5th gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR) <DTC P0735>

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0846: 2-6 brake pressure switch system

- P0876: High clutch pressure switch system

- P0988: Low-reverse brake pressure switch system

Sensor (The sensor below is determined to be normal)

- Input shaft speed sensor

- Output shaft speed sensor

- Transmission range switch

- Lock-up and low-reverse brake linear solenoid

- Low clutch linear solenoid

- 2-6 brake linear solenoid

- 3-5 reverse clutch linear solenoid

- High clutch linear solenoid

- Low clutch shift solenoid

- Low-reverse brake shift solenoid

- Engine revolution signal

- CAN communication

DTC SET CONDITIONS <DTC P0735>

Check Conditions

- Shift stage: 5th gear.

- Time after shift changing finish: 2 seconds or more.

Judgment Criteria

- Gear ratio: 1.008 or more. (2 seconds)

OBD-II DRIVE CYCLE PATTERN <DTC P0735>

5th gear driving for 5 seconds or more

PROBABLE CAUSES

- Transaxle assembly powertrain parts failure

- When the DTC P0715: Input shaft speed sensor system is stored

- When the DTC P0720: Output shaft speed sensor system is stored

- When the DTC P0962, P0963: Line pressure linear solenoid valve system is stored

- When the DTC P0973, P0974: Low clutch linear solenoid valve system is stored

- When the DTC P0976, P0977: 2-6 brake linear solenoid valve system is stored

- When the DTC P0979, P0980: 3-5 reverse clutch linear solenoid valve system is stored

- When the DTC P0982, P0983: High clutch linear solenoid valve system is stored

- When the DTC P0998, P0999: Low clutch shift solenoid valve system is stored

- Malfunction of the low clutch, 2-6 brake, 3-5 reverse clutch, high clutch

- Malfunction of the valve body assembly

DIAGNOSIS

STEP 1. Check the DTC.

Check that P0715 (input shaft speed sensor) and P0720 (output shaft speed sensor) are set. Check and repair the relevant DTC system.

Check and repair the relevant DTC system.

Is the DTC stored?

Check and repair the relevant DTC system.

Check and repair the relevant DTC system.STEP 2. Check the DTC.

Check that the DTC other than P0729, P0732, P0733, P0734, P0735 (6th, 2nd, 3rd, 4th, 5th gear ratio) is stored. Check and repair the relevant DTC system.

Check and repair the relevant DTC system.

Is the DTC stored?

Check and repair the relevant DTC system.

Check and repair the relevant DTC system.STEP 3. Check the transmission fluid properties.

Check the status of the transmission fluid properties (smell, color, fouling). Remove the A/T from the vehicle, then check and repair the inside.

Remove the A/T from the vehicle, then check and repair the inside.

- Black: A/T inside damage, seizure

- Milky: Water intrusion

Is the check result normal?

Remove the A/T from the vehicle, then check and repair the inside.

Remove the A/T from the vehicle, then check and repair the inside.STEP 4. Check the transmission fluid level.

STEP 5. Check the signals of input shaft speed sensor and output shaft speed sensor.

Check the signals of TCM connector PGA1, PGB1 terminal. Repair or replace the failure section.

Repair or replace the failure section.

Is the check result normal?

Repair or replace the failure section.

Repair or replace the failure section.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)