REGULATED VOLTAGE TEST

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

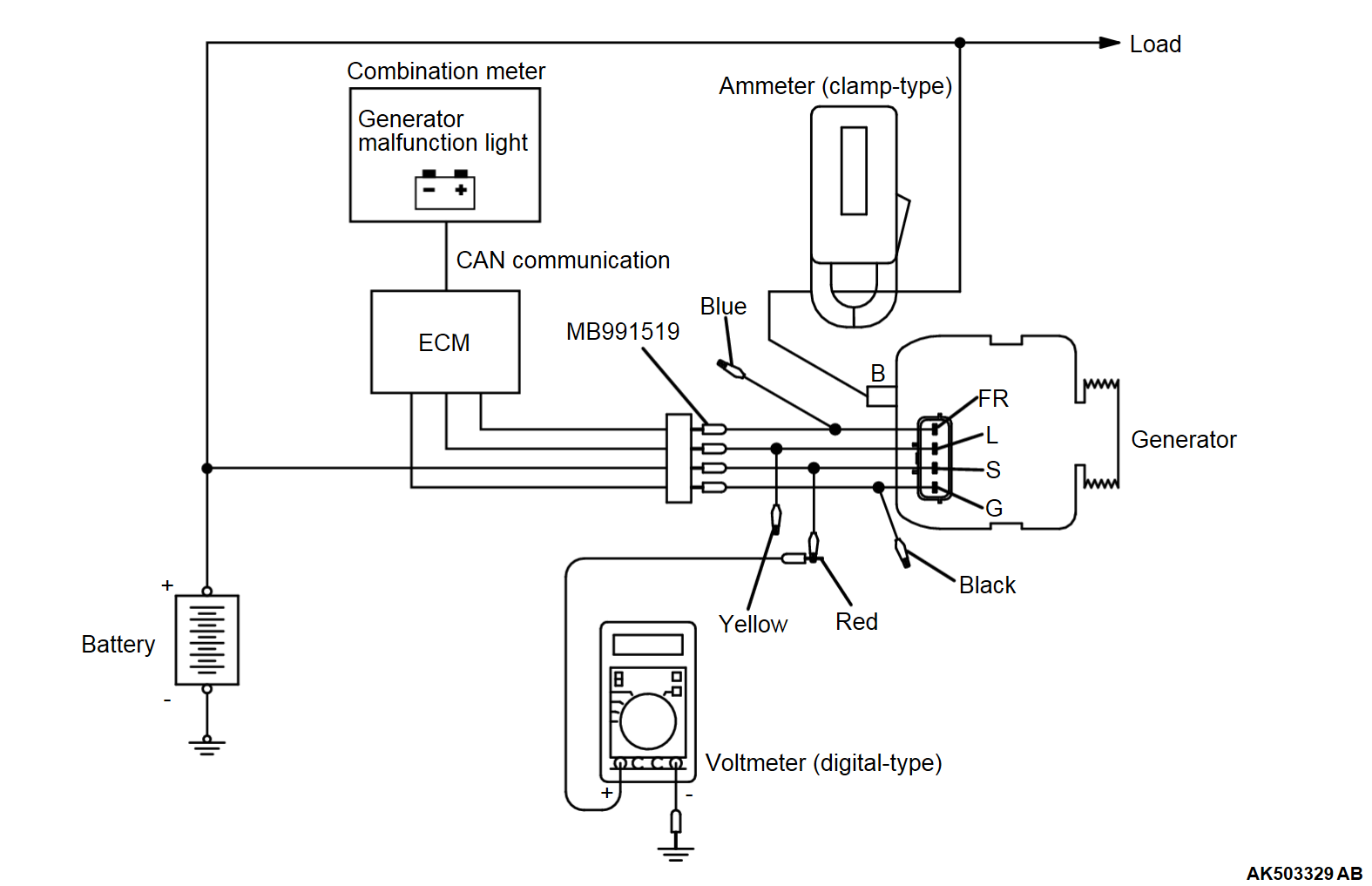

- MB991519: Generator test harness

This test determines whether the voltage regulator correctly controlling the generator output voltage.

1.

| warning | Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after handling. |

Always be sure to check the following before the test.

- Generator installation

- Check that the battery installed in the vehicle is fully charged. (Refer to GROUP 54A - Battery - On-vehicle Service, Battery Test

).

). - Drive belt tension. [Refer to GROUP 00 - Maintenance Service, Drive Belt (For Water Pump and Generator) (Check Condition)

].

]. - Fusible link

- Abnormal noise from the generator while the engine is running

2. Turn the ignition switch to the "LOCK" (OFF) position.

3. Disconnect the negative battery cable.

4. Use special tool MB991519 to connect a digital voltmeter between the generator "S" terminal and ground (Connect the positive lead of the voltmeter to the "S" terminal, and then connect the negative lead of the voltmeter to a secure ground or to the negative battery terminal).

5. Set a clamp-type DC test ammeter to the generator "B" terminal output wire.

6. Reconnect the negative battery cable.

7.

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

8. Turn the ignition switch to the "ON" position and check that the reading on the voltmeter is equal to the battery voltage.

| note | If the voltage is 0 V, the cause is probably an open circuit in the wire or fusible link between the generator "S" terminal and the positive battery terminal. |

9. Turn all lights and accessories off.

10. Start the engine.

11. Increase the engine speed to 2,500 r/min.

12. Read the value displayed on the voltmeter when the generator output current generator becomes 15 A or less.

13. If the voltage reading conforms to the value in the voltage regulation table, then the voltage regulator is operating normally.

If the voltage is not within the standard value, there is a malfunction of the voltage regulator or of the generator.

14. After the test, lower the engine speed to the idle speed.

15. Turn the ignition switch to the "LOCK" (OFF) position.

16. Disconnect the scan tool (M.U.T.-III) to the data link connector.

17. Disconnect the negative battery cable.

18. Disconnect the ammeter and voltmeter.

19. Remove the special tool, and return the connector to the original condition.

20. Connect the negative battery cable.

Voltage Regulation Table

STANDARD VALUE <2.4L ENGINE>

| Inspection terminal | Voltage regulator ambient temperature °C (°F) | Voltage V |

| Terminal "S" | -20 (-4) | 14.2 - 15.4 |

| 20 (68) | 13.9 - 14.9 | |

| 60 (140) | 13.4 - 14.6 | |

| 80 (176) | 13.1 - 14.5 |

STANDARD VALUE <3.0L ENGINE>

| Inspection terminal | Voltage regulator ambient temperature °C (°F) | Voltage V |

| Terminal "S" | -20 (-4) | 14.0 - 15.1 |

| 20 (68) | 13.7 - 14.6 | |

| 60 (140) | 13.2 - 14.3 | |

| 80 (176) | 12.9 - 14.1 |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)