DTC P0221: Throttle Position Sensor (Sub) Plausibility

TECHNICAL DESCRIPTION

Compare the actual measurement of volumetric efficiency by a mass airflow sensor signal with volumetric efficiency estimated from a throttle position sensor (sub) signal.

MONITOR EXECUTION

Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- The difference between the actual volumetric efficiency and the volumetric efficiency estimated by the throttle position sensor (sub) is 0 percent or more. Or, the volumetric efficiency is 60 percent or less.

- Engine speed is 750 r/min or higher.

Judgment Criterion

- For 0.4 second, the difference between the actual volumetric efficiency and the volumetric efficiency estimated by the throttle position sensor (sub) is 33 percent or more.

- For 0.4 second, the difference between the volumetric efficiency estimated by the throttle position sensor (main) and the volumetric efficiency estimated by the throttle position sensor (sub) is 8.8 percent or more.

Check Conditions

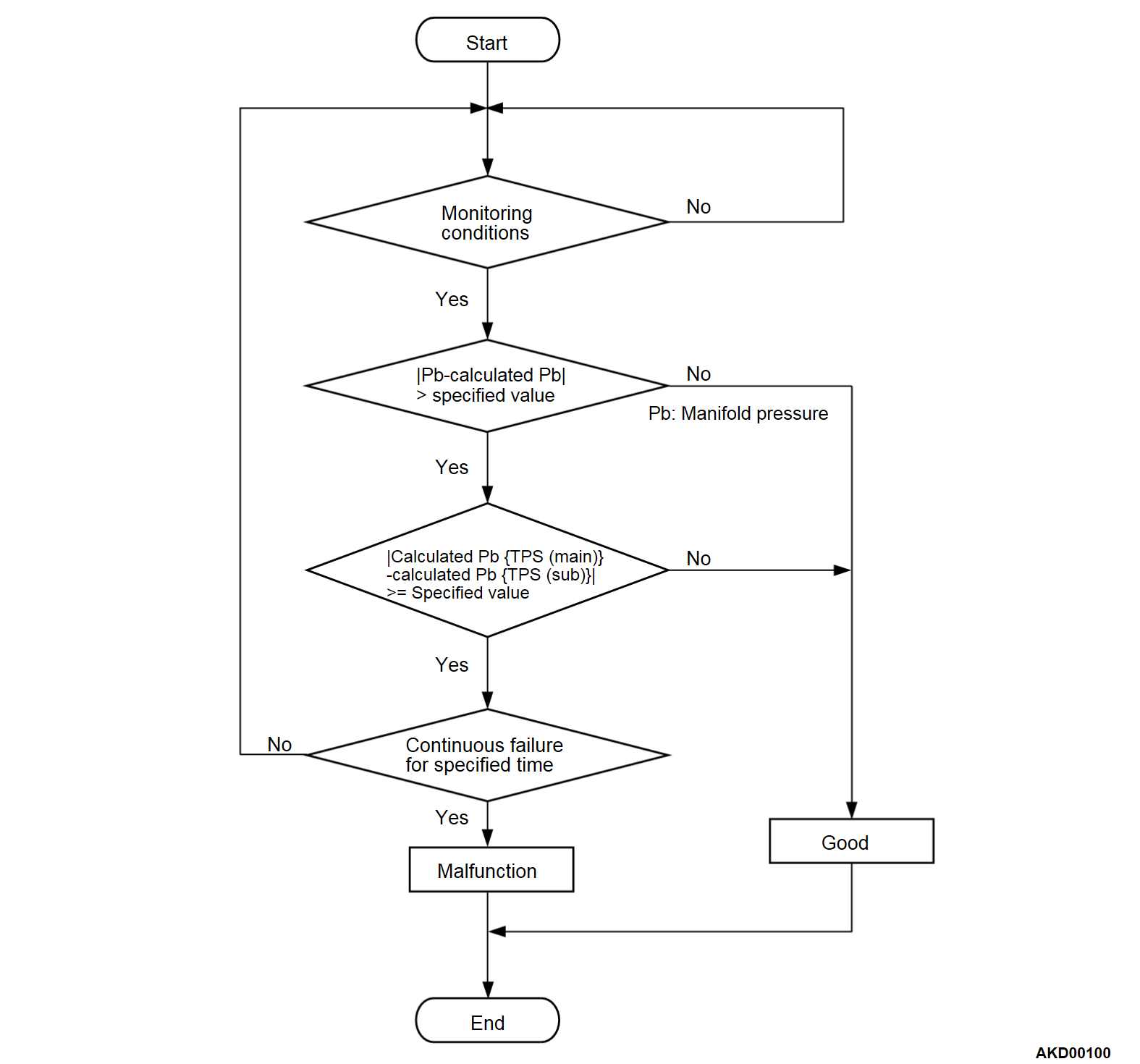

- The difference between the actual manifold pressure and the manifold pressure estimated by the throttle position sensor (sub) is 0 kPa (0 in.Hg) or more. Or, the manifold pressure is 73 kPa (21.6 in.Hg) or less.

- Engine speed is 750 r/min or higher.

Judgment Criterion

- For 0.4 second, the difference between the actual manifold pressure and the manifold pressure estimated by the throttle position sensor (sub) is 40 kPa (11.8 in.Hg) or more.

- For 0.4 second, the difference between the manifold pressure estimated by the throttle position sensor (main) and the manifold pressure estimated by the throttle position sensor (sub) is 7 kPa (2.1 in.Hg) or more.

FAIL-SAFE AND BACKUP FUNCTION

- Throttle opening degree is restricted.

- Throttle opening degree position is in default position if throttle position sensor (main) fails.

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are: )

- Throttle position sensor (sub) system failed.

- Intake system vacuum leak.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

STEP 1. Using scan tool (M.U.T.-III), read the diagnostic trouble code (DTC).

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Turn the ignition switch to the "ON" position.

(3) Read the DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the diagnostic trouble code other than P0221 stored?

STEP 2. Using scan tool (M.U.T.-III), check data list item 15: Throttle Position Sensor (sub).

(1) Detach the intake air hose at the throttle body.

(2) Disconnect the connector of the throttle body assembly.

(3) Use test harness special tool (MB991658) to connect only terminals TPSE, TPSM, TPS5, and TPSS line.

(4) Turn the ignition switch to the "ON" position.

(5) Set scan tool (M.U.T.-III) to the data reading mode for item 15, Throttle Position Sensor (sub).

- Output voltage should be 4.0 volts or more when the throttle valve is fully closed with your finger.

- Output voltage should be 1.0 volt or less when the throttle valve is fully open with your finger.

(6) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 3. Check for intake system vacuum leak.

STEP 4. Check for foreign matter being around the mass airflow sensor.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)