DTC P0137: Heated Oxygen Sensor Circuit Low Voltage (bank 1, sensor 2)

CIRCUIT OPERATION

- A voltage corresponding to the oxygen concentration in the exhaust gas is sent to the ECM terminal O2RR from the output terminal of the right bank heated oxygen sensor (rear).

- Terminal of the right bank heated oxygen sensor (rear) is grounded with ECM terminal ORRE.

- The ECM applies an off set voltage of 0.5 volt to ground terminal of the right bank heated oxygen sensor (rear).

TECHNICAL DESCRIPTION

- The output signal of the right bank linear air-fuel ratio sensor is compensated by the output signal of the right bank heated oxygen sensor (rear).

- The ECM checks for the right bank heated oxygen sensor (rear) output voltage.

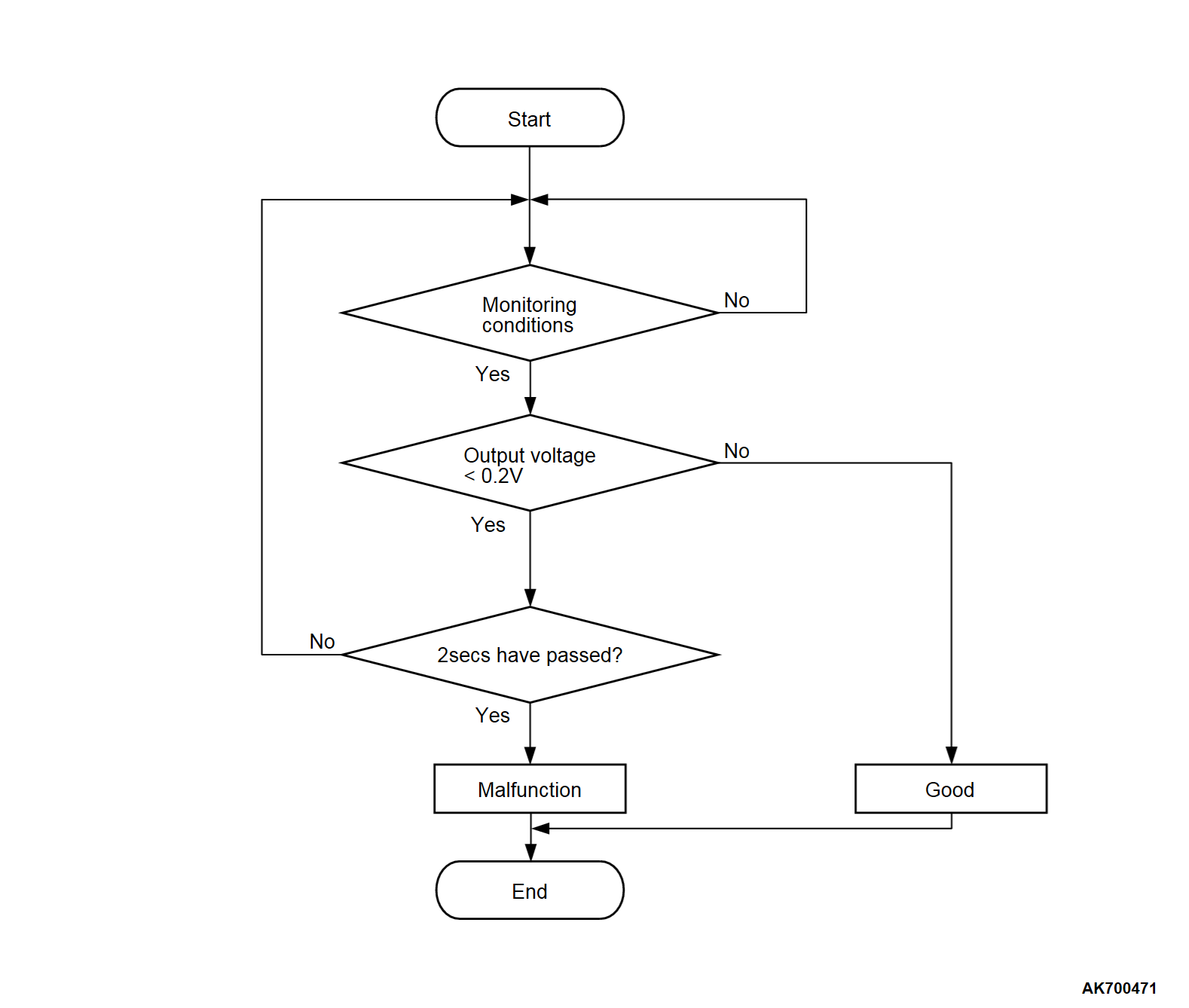

DESCRIPTIONS OF MONITOR METHODS

- Right bank heated oxygen sensor (rear) output voltage is under the specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Right bank linear air-fuel ratio sensor heater monitor

- Right bank heated oxygen sensor (rear) heater monitor

- Right bank linear air-fuel ratio sensor monitor

- Right bank linear air-fuel ratio sensor inactive monitor

- Right bank heated oxygen sensor offset voltage monitor

- Air/fuel ratio feedback monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

Check Conditions

- Heated oxygen sensor offset voltage is between 0.4 and 0.6 volt.

- Battery positive voltage is between 11 and 16.5 volts.

- 3 minutes or more have passed since the engine starting sequence was completed.

Judgment Criterion

- Right bank heated oxygen sensor (rear) output voltage is lower than 0.2 volt for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Right bank heated oxygen sensor (rear) failed.

- Connector damage.

- Harness damage

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle Communication Interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite Main Harness A

- MB992747: V.C.I.-Lite USB Cable Short

- MB992748: V.C.I.-Lite USB Cable Long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

- MB991658: Test Harness

- MB992110: Power Plant ECU Check Harness

STEP 1. Using scan tool (M.U.T.-III), check data list item AD: Heated Oxygen Sensor Bank 1, Sensor 2 (right rear).

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Start the engine and run at idle.

(3) Set scan tool (M.U.T.-III) to the data reading mode for item AD, Heated Oxygen Sensor Bank 1, Sensor 2 (right rear).

- Transaxle: 2nd

- Drive with wide open throttle

- Engine: 3,500 r/min

- The output voltages should be between 0.6 and 1.0 volt.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 2. Measure the sensor output voltage at right bank heated oxygen sensor (rear) connector by backprobing

(1) Do not disconnect the right bank heated oxygen sensor (rear) connector.

(2) Start the engine and run at idle.

(3) Measure the voltage between terminal O2RR line and ground by backprobing under the following driving.

- Transaxle: 2nd

- Drive with wide open throttle

- Engine: 3,500 r/min or more

- The output voltage should be between 1.0 and 1.5 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage within the specified range?

STEP 3. Measure the sensor output voltage at ECM connector by using power plant ECU check harness special tool MB992110.

(1) Disconnect all ECM connectors. Connect the power plant ECU check harness special tool MB992110 between the separated connectors.

(2) Start the engine and run at idle.

(3) Measure the voltage between terminal O2RR and ground by backprobing under the following driving.

- Transaxle: 2nd

- Drive with wide open throttle

- Engine: 3,500 r/min or more

- The output voltage should be between 1.0 and 1.5 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 1.0 and 1.5 volts?

STEP 4. Measure the sensor offset voltage at ECM connector by using power plant ECU check harness special tool MB992110.

(1) Disconnect all ECM connectors. Connect the power plant ECU check harness special tool MB992110 between the separated connectors.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal ORRE and ground.

- Voltage should be between 0.4 and 0.6 volt.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 0.4 and 0.6 volt?

STEP 5. Check of open circuit and harness damage in ORRE line between right bank heated oxygen sensor (rear) connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Check of short circuit to ground in O2RR line between right bank heated oxygen sensor (rear) connector and ECM connector.

Is the harness wire in good condition?

STEP 7. Check the right bank heated oxygen sensor (rear).

(1) Disconnect the right bank heated oxygen sensor (rear) connector and connect test harness special tool MB991658 to the connector on the right bank heated oxygen sensor (rear) side.

(2) Warm up the engine until engine coolant temperature reaches 80°C (176°F) or higher.

(3) Drive at 50 km/h (31mph) or more for 10 minutes.

(4) Connect a digital voltage meter between terminal O2RR line and terminal O2LE line.

(5) Measure the output voltage of heated oxygen sensor under the following driving.

- Transaxle: 2nd

- Drive with wide open throttle

- Engine: 3,500 r/min or more

Standard value: 0.6 - 1.0 V

| note | If the temperature of sensing area does not reach the high temperature [of approximately 400°C (752°F) or more] even though the heated oxygen sensor is normal, the output voltage would be possibly low in spite of the rich air/fuel ratio. |

| note | When the vehicle is driven with high loads, the temperature of the sensing area of the heated oxygen sensor is sufficiently high. Thus, it is not necessary to apply the voltage to the heater. |

Is the measured voltage between 0.6 and 1.0 volt?

STEP 8. Using scan tool (M.U.T.-III), check data list item AD: Right Bank Heated oxygen sensor (rear).

(1) Start the engine and run at idle.

(2) Set scan tool (M.U.T.-III) to the data reading mode for item AD, Right Bank Heated oxygen sensor (rear).

- Transaxle: 2nd

- Drive with wide open throttle

- Engine: 3,500 r/min or more

- The output voltage should be between 0.6 and 1.0 volt.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)