DTC P265B: Variable Valve Lift Control Motor Position Sensor Circuit

CIRCUIT OPERATION

- A power voltage of 5 V is applied to the variable valve lift control motor from the valve lift ECU terminal HS5V.

- The power voltage is grounded to the valve lift ECU terminal HSE from the variable valve lift control motor.

- The sensor signal is inputted to the valve lift ECU terminal HSWS, HSVS and HSUS from the variable valve lift control motor-integrated Hall sensor output terminal.

TECHNICAL DESCRIPTION

- The valve lift ECU uses the variable valve lift control motor-integrated Hall sensor signal to detect motor rotation angle.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Variable valve lift system monitor

Sensor (The sensor below is determined to be normal)

- Not applicable

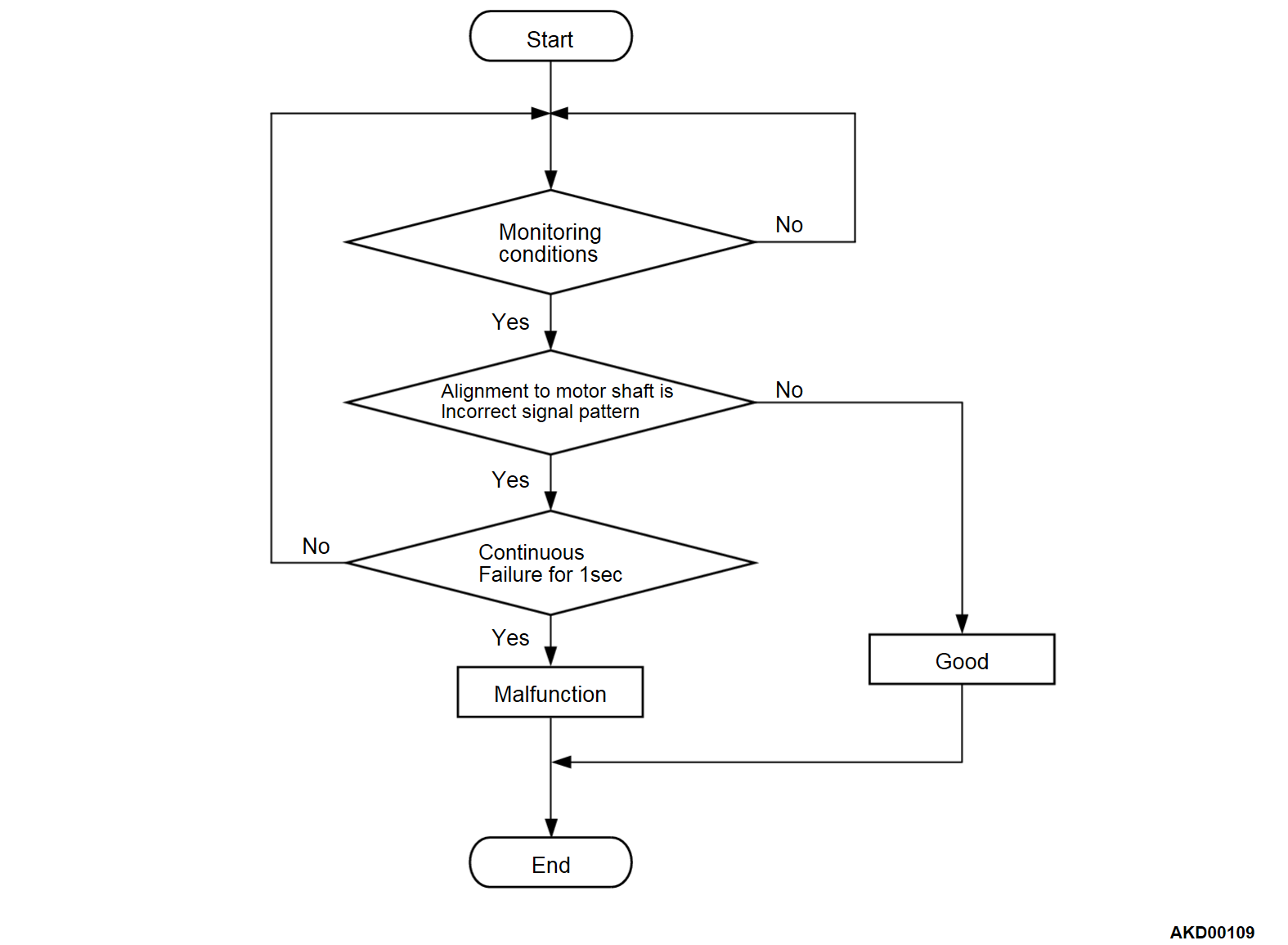

DTC SET CONDITIONS

Check Condition

- More than 0.2 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- The ECM has received malfunction from the valve lift ECU via VLC-CAN.

- Contents of malfunction which the valve lift ECU detects

- The system has detected an abnormal output pattern (all High or Low) in the U, V and W-phase position sensor signals.

FAIL-SAFE AND BACKUP FUNCTION

- Deenergizes the variable valve lift control motor.

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are: )

- Open or shorted variable valve lift control motor-integrated Hall sensor circuit, harness damage, or connector damage.

- Variable valve lift control motor (hall sensor) failed.

- Valve lift ECU failed.

DIAGNOSIS

STEP 1. Measure the sensor supply voltage at variable valve lift control motor harness side connector.

(1) Disconnect the variable valve lift control motor connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal HS5V line and ground.

- Voltage should be between 4.9 and 5.1 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 4.9 and 5.1 volts?

STEP 2. Check of short to ground and open circuit in HS5V line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 3. Check of harness damage in HS5V line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 4. Check the continuity at variable valve lift control motor harness side connector.

(1) Disconnect the variable valve lift control motor connector and measure at the harness side.

(2) Measure the continuity between terminal HSE line and ground

- Continuity (2 ohms or less)

Does continuity exist?

STEP 5. Check of open circuit and harness damage in HSE line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 6. Check of open circuit and harness damage in HSUS line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 7. Check of open circuit and harness damage in HSVS line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 8. Check of open circuit and harness damage in HSWS line between variable valve lift control motor connector and valve lift ECU connector.

Is the harness wire in good condition?

STEP 9. Check of open circuit and harness damage in shield line between variable valve lift control motor connector and ground.

Is the harness wire in good condition?

STEP 10. Replace the variable valve lift control motor.

(1) Replace the variable valve lift control motor.

(2) Turn the ignition switch to the "ON" position.

(3) After the DTC has been deleted, read the DTC again.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC P265B stored?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)