DTC P053F: Cold Start Fuel Rail Pressure Performance

TECHNICAL DESCRIPTION

The cause may mainly lie in abnormally low fuel pressure or high fuel pressure during the warm-up.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Fuel pump (high pressure) monitor

Sensor (The sensor below is determined to be normal)

- Fuel rail pressure sensor

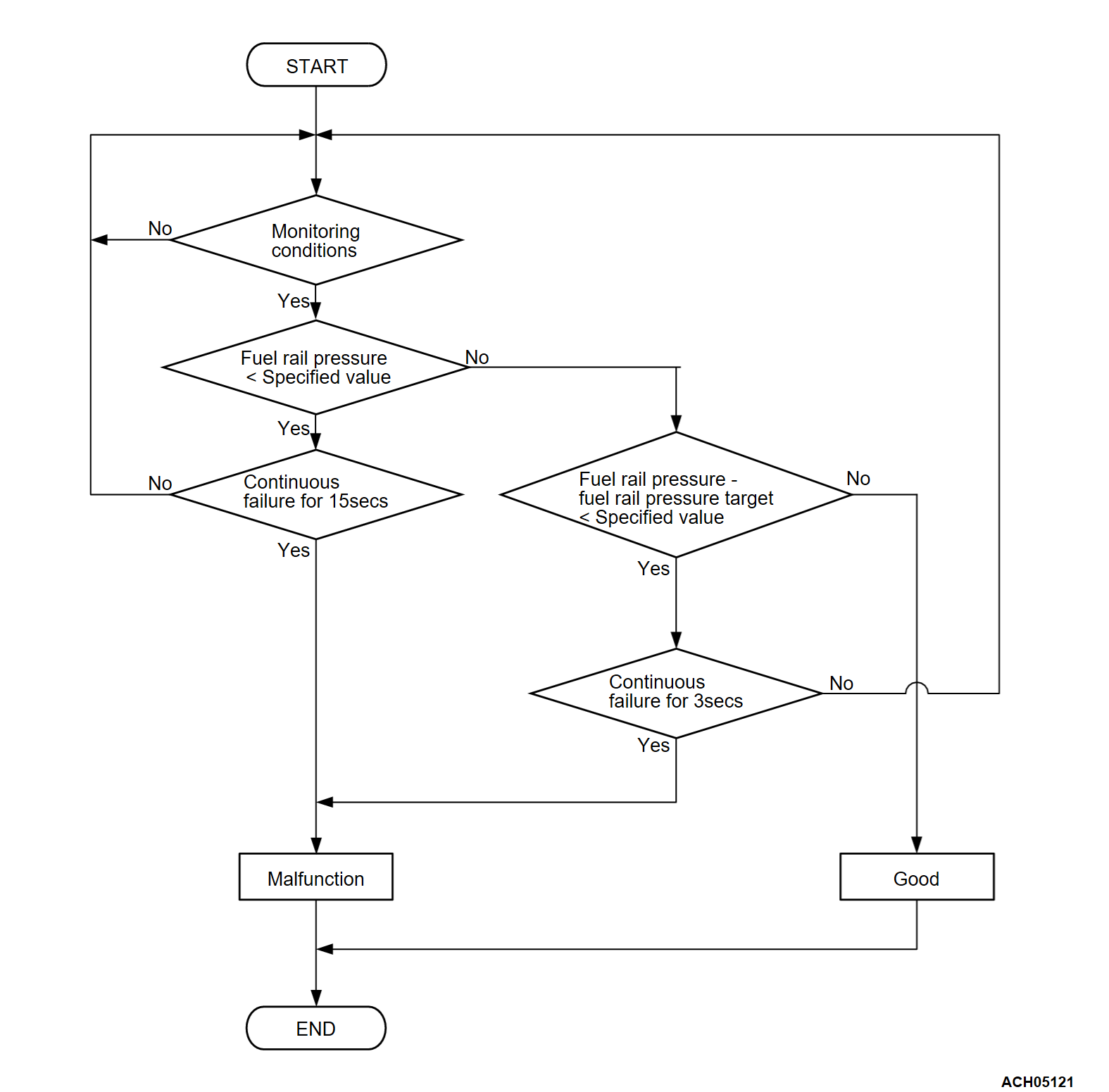

Check Conditions

- More than 3 seconds have passed since the engine starting sequence was completed.

- Battery positive voltage is higher than 10 volts.

- The estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals lower than 0 kPa (0 in.Hg).

Judgment Criteria

- The fuel rail pressure is lower than the specified value for 15 seconds.

- Under the ignition timing retard control.

or

- For 3 seconds, the estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals lower than the specified value.

- Under the ignition timing retard control.

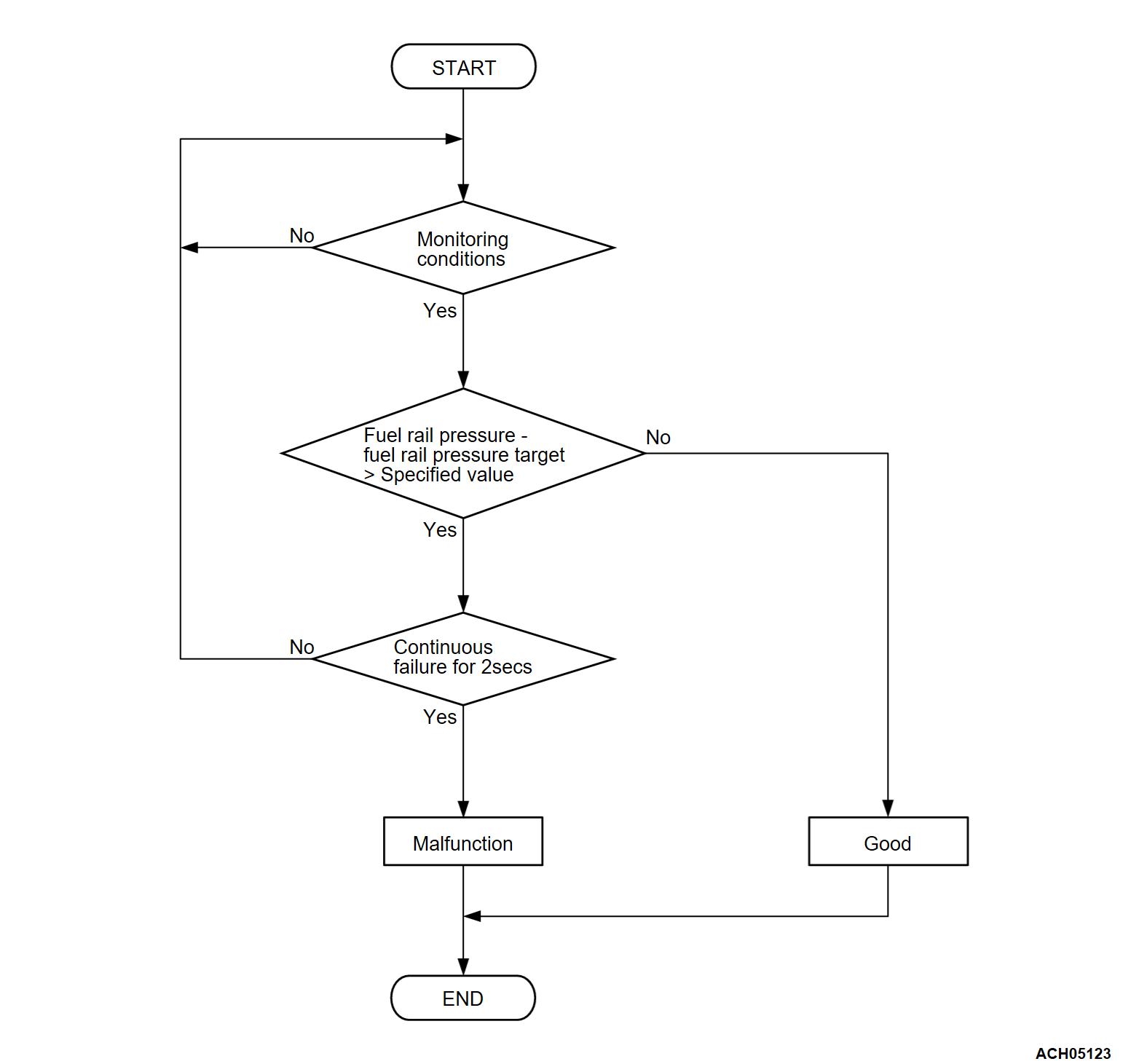

Check Conditions

- More than 3 seconds have passed since the engine starting sequence was completed.

- Battery positive voltage is higher than 10 volts.

- Fuel injection mode is not MFI-mode.

- The estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals 0 kPa (0 in.Hg) or higher.

Judgment Criteria

- For 2 seconds, the estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals higher than the specified value.

- Under the ignition timing retard control.

| note | Stop the monitor within 3 seconds of starting the DFI and MFI mode, or stop the monitor within 10 seconds of exceeding the fuel rail pressure of 20,000 kPa (5,906.7 in.Hg) in the DFI and MFI mode. |

FAIL-SAFE AND BACKUP FUNCTION

- None.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Fuel rail pressure sensor circuit harness damage, or connector damage.

- Fuel pump (high pressure) circuit harness damage, or connector damage.

- Fuel rail pressure sensor failed.

- Fuel pump (high pressure) failed.

- Fuel pump failed.

- Fuel line failed.

- Injector (high pressure) failed.

- ECM failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check freeze frame data (OBD) item 124: Fuel rail pressure sensor (Absolute).

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Turn the ignition switch to the "ON" position.

(3) Read the freeze frame data (OBD) of DTC P053F.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the fuel rail pressure between 10,000 and 13,000 kPa (2953.4 and 3839.3 in.Hg)?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)