DTC P0087: Fuel System Pressure Too Low

CIRCUIT OPERATION

TECHNICAL DESCRIPTION

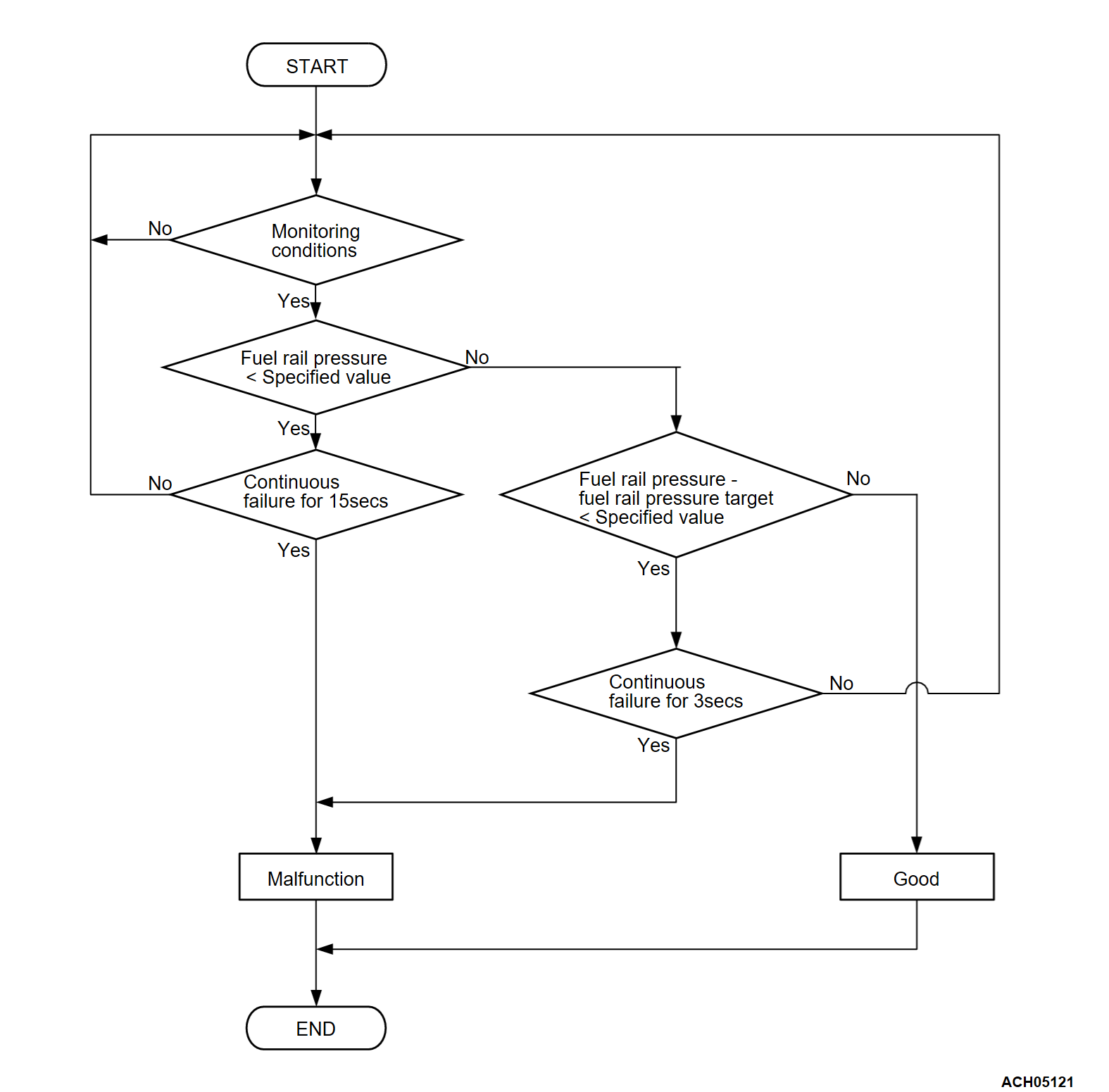

- The ECM monitors the signals input from the fuel rail pressure sensor.

- Based on the input signals, the ECM checks whether the fuel rail pressure drops the minimum pressure of the system.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Fuel pump (high pressure) monitor

Sensor (The sensor below is determined to be normal)

- Fuel rail pressure sensor

Check Conditions

- More than 3 seconds have passed since the engine starting sequence was completed.

- Battery positive voltage is higher than 10 volts.

- The estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals lower than 0 kPa (0 in.Hg).

Judgment Criteria

- The fuel rail pressure is lower than the specified value for 15 seconds.

or

- For 3 seconds, the estimated fuel rail pressure subtracted from the fuel rail pressure sensor output equals lower than the specified value.

FAIL-SAFE AND BACKUP FUNCTION

- While prohibiting the operation of the injector (high pressure), carry out the control by the injector operation only.

- Torque is restricted.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Fuel rail pressure sensor circuit harness damage, or connector damage.

- Fuel pump (high pressure) circuit harness damage, or connector damage.

- Fuel rail pressure sensor failed.

- Fuel line failed.

- Fuel pump failed.

- Fuel pump (high pressure) failed.

- Injector (high pressure) failed.

- High-pressure fuel line failed.

- ECM failed.

- Run out of fuel

DIAGNOSIS

STEP 1. Check the fuel level.

STEP 2. Check high-pressure fuel line and fuel line.

- By a visual inspection and odor inspection, check around the high-pressure fuel line from the fuel pump (high pressure) to the injector (high pressure), and around the fuel line. Ensure that there is not fuel seepage and fuel leaks.

- Remove the spark plug and check whether you smell the fuel from the plug hole or not. If you smell fuel, check a fuel leak from the injector (high pressure).

Are there any abnormalities?

STEP 4. Check of harness damage in HFP5 line between fuel rail pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 5. Check of harness damage in HFPS line between fuel rail pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Check of harness damage in HFPG line between fuel rail pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 7. Check of harness damage in HFP+ line between fuel pump (high pressure) connector and ECM connector.

Is the harness wire in good condition?

STEP 8. Check of harness damage in HFP- line between fuel pump (high pressure) connector and ECM connector.

Is the harness wire in good condition?

STEP 9. Check fuel pump (high pressure) mounting position.

- Ensure that the plunger of the fuel pump (high pressure) and tappet do not have abrasion and damage.

- Check whether the pump cam of the exhaust camshaft is worn down or not.

Are there any abnormalities?

STEP 10. Check the trouble symptoms.

(1) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 2  .

.

.

.(2) Check the diagnostic trouble code (DTC).

Is DTC P0087 set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)