DTC P062B: Direct Fuel Injection Control Performance

CIRCUIT OPERATION

Battery voltage is applied to the ECM connector terminal DIB1, DIB2, DIB3 and DIB4 from the MFI relay.

TECHNICAL DESCRIPTION

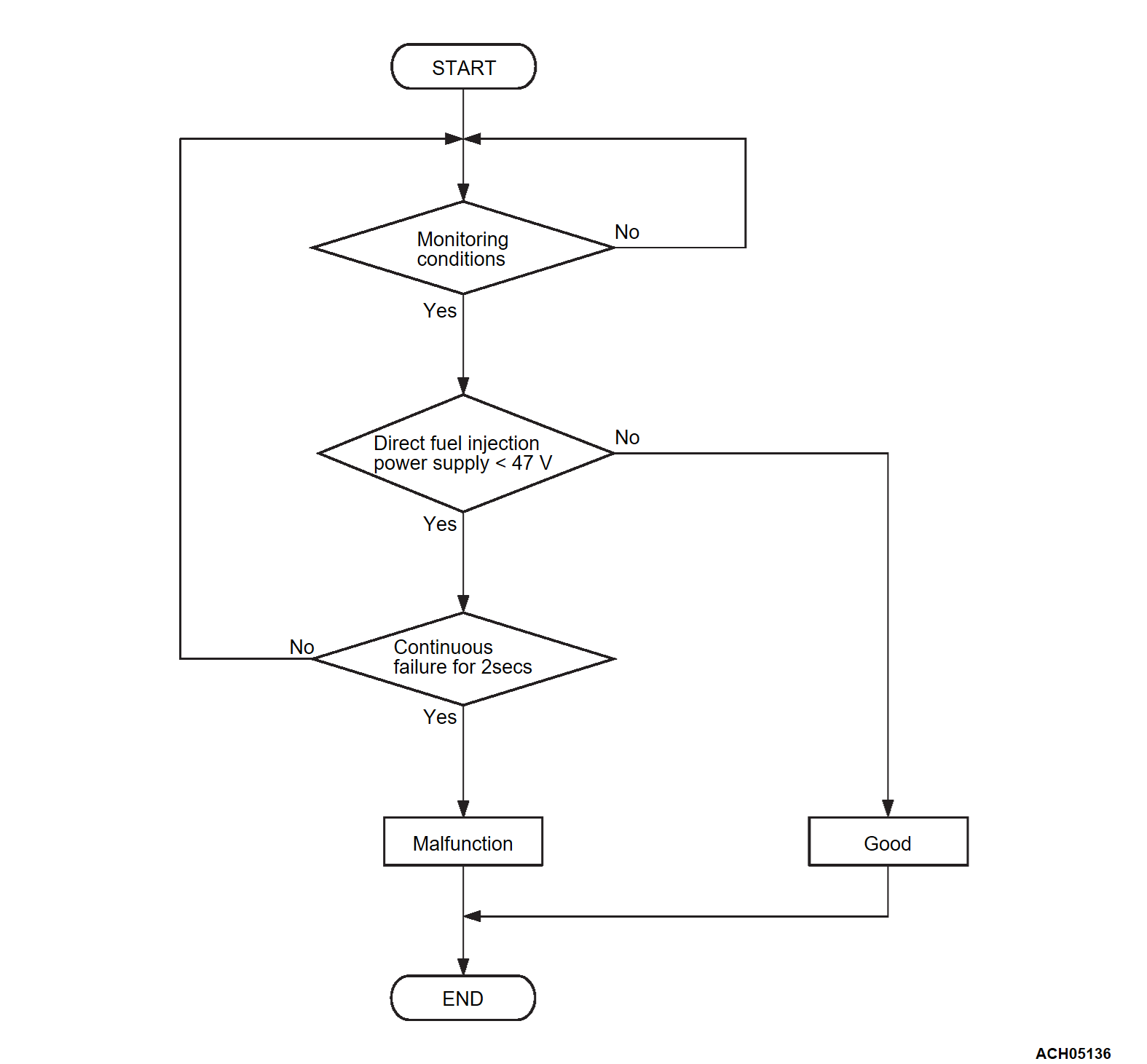

ECM checks the injector (high pressure) power voltage for abnormal conditions.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Ignition switch is "ON" position.

- After 2 seconds pass from the time when the engine is stopped.

- Battery positive voltage is higher than 10 volts.

Judgment Criterion

- Boosted voltage for injector (high pressure) is less than 47 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- While prohibiting the operation of the injector (high pressure), carry out the control by the injector operation only.

- Torque is restricted.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Open or shorted injector (high pressure) circuit, harness damage or connector damage.

- Blown fuse

- ECM failed.

DIAGNOSIS

STEP 1. Check power supply fuse.

Is the fuse in good condition?

STEP 2. Measure the power supply voltage at ECM connector.

(1) Disconnect the ECM connector, and measure at harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal DIB1 and ground.

- Voltage should be battery positive voltage.

(4) Measure the voltage between terminal DIB2 and ground.

- Voltage should be battery positive voltage.

(5) Measure the voltage between terminal DIB3 and ground.

- Voltage should be battery positive voltage.

(6) Measure the voltage between terminal DIB4 and ground.

- Voltage should be battery positive voltage.

(7) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

STEP 3. Check of harness damage in DIB1 line between MFI relay connector and ECM connector.

Is the harness wire in good condition?

STEP 4. Check of harness damage in DIB2 line between MFI relay connector and ECM connector.

Is the harness wire in good condition?

STEP 5. Check of harness damage in DIB3 line between MFI relay connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Check of harness damage in DIB4 line between MFI relay connector and ECM connector.

Is the harness wire in good condition?

STEP 7. Check the continuity at ECM harness side connector.

(1) Disconnect the ECM connector and measure at the harness side.

(2) Measure the continuity between terminal DIG1 and ground.

- Continuity (2 ohms or less)

(3) Measure the continuity between terminal DIG2 and ground.

- Continuity (2 ohms or less)

(4) Measure the continuity between terminal DIG3 and ground.

- Continuity (2 ohms or less)

(5) Measure the continuity between terminal DIG4 and ground.

- Continuity (2 ohms or less)

Does continuity exist?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)