FUEL PRESSURE TEST

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB992001: Hose Adapter

- MB992049: Quick Connector

- MB992076: Injector Test Set

- MD998709: Hose Adapter

<Measurement of fuel pressure between the fuel pump and injector>

2.

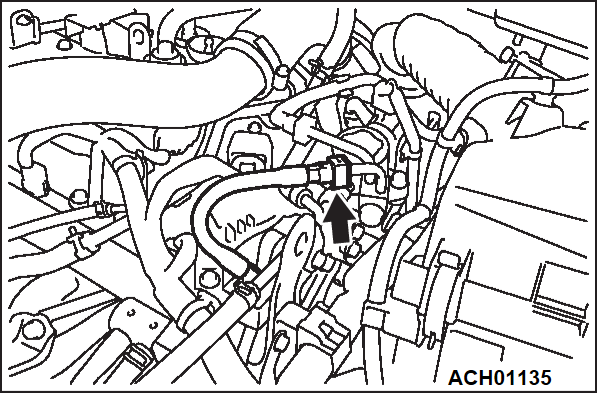

Disconnect the fuel injection tube at the fuel pump (high pressure) suction tube side.

| warning | To prevent a fire, cover the hose connection with shop towels to prevent splashing of fuel that could be caused by some residual pressure in the fuel pipe line. |

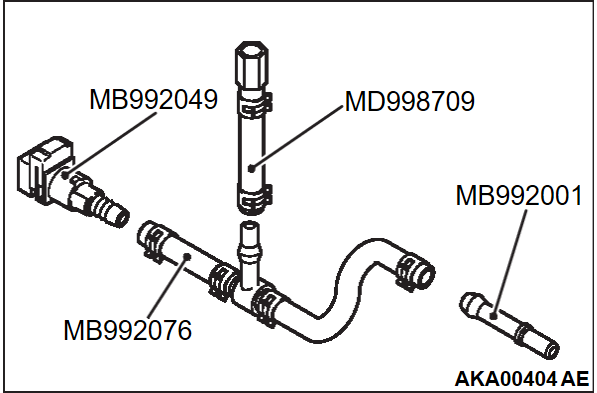

3. Assemble the special tool MB992076 (injector test set) as shown in figure according to the following procedure.

(1) Remove the injector installation adapter from the hose. Remove another hose together with the adapter and remove the adapter from the remaining hose.

(2) Install the special tool MB992049 (quick connector) and the special tool MB992001 (hose adapter) to the hose without the adapter.

(3) Remove the nipple of the bolt of the special tool MD998709 (hose adapter).

(4) Install the special tool prepared in the procedure (3) to the nipple that was removed together with hose in the procedure (1).

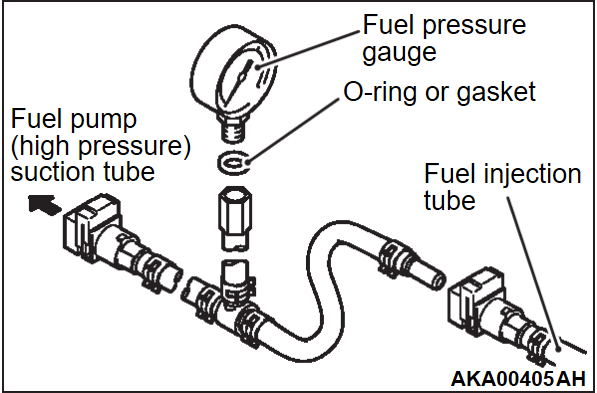

4. Install the special tool assembled in Step 3 between the fuel injection tube and the fuel pump (high pressure) suction tube.

5. Via a suitable O-ring or gasket, install the fuel pressure gauge to the special tool that has already assembled as described.

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

7. Turn the ignition switch to the ON position (but do not start the engine).

8. Use Actuator test "item number 2" to drive the fuel pump. Check that there is no fuel leaking from any section when the fuel pump is operating.

9. Finish the actuator test or turn the ignition switch to the LOCK (OFF) position.

10. Start the engine and run at idle.

11. Measure fuel pressure while the engine is running at idle.

Standard value: Approximately 450 kPa (132.9 in.Hg) at curb idle

12. Check to see that fuel pressure at idle does not drop even after the engine has been revved several times.

13. If any of fuel pressure measured in Step 10 to 12 is out of specification, troubleshoot and repair according to the table below.

| SYMPTOM | PROBABLE CAUSE | REMEDY |

| Clogged fuel filter | Replace fuel filter |

| Fuel leaking to return side due to poor fuel regulator valve seating or settled spring | Replace fuel pressure regulator (integrated in the fuel pump module) | |

| Low fuel pump delivery pressure | Replace fuel pump | |

| Fuel pressure too high | Binding valve in fuel pressure regulator |

|

| note | *: When the fuel pressure is 600 kPa (87.0 psi) or more or the components are deformed or damaged, replace them. |

14. Stop the engine and observe fuel pressure gauge reading. It is normal if the reading does not drop within 2 minutes. If it does, observe the rate of drop and troubleshoot and repair according to the table below. Start, then stop the engine.

| SYMPTOM | PROBABLE CAUSE | REMEDY |

| Fuel pressure drops gradually after engine is stopped | Leaky injector | Replace injector |

| Leaky fuel regulator valve seat | Replace fuel pressure regulator (integrated in the fuel pump module) | |

| Fuel pressure drops sharply immediately after engine is stopped | Check valve in fuel pump is held open | Replace fuel pump |

16.

| warning | To prevent a fire, cover the hose connection with shop towels to prevent splash of fuel that could be caused by some residual pressure in the fuel pipe line. |

Remove the fuel pressure gauge and special tool from the fuel pump (high pressure) suction tube.

17. Fit the fuel injection tube to the fuel pump (high pressure) suction tube.

18. Check for fuel leaks.

(1) Use scan tool (M.U.T.-IIISE) to operate the fuel pump.

(2) Check the fuel line for leaks and repair as needed.

19. Disconnect scan tool (M.U.T.-IIISE).

<Measurement of fuel pressure between the fuel pump (high pressure) and injector (high pressure)>

| note | Perform the fuel pressure measurement between the fuel pump (high pressure) and injector (high pressure) after confirming that the fuel pressure between the fuel pump and injector is normal. |

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

2. Start the engine.

3. Warm up the engine until the engine coolant temperature reaches 80°C (176°F) or higher.

4. Set scan tool (M.U.T.-IIISE) to data reading mode for item 124, Fuel Rail Pressure Sensor (Absolute) while the engine is running at idle.

Standard value: 4,000 - 21,000 kPa (1,181.4 - 6,202.0 in.Hg) at curb idle

5. Check to see that fuel pressure at idle does not drop even after the engine has been revved several times.

6. Turn the ignition switch to the "LOCK" (OFF) position, and stop the engine.

7. If any of fuel pressure measured in steps 3 to 4 is out of specification, perform the following inspection.

(1) Start the engine, and maintain a stable idle speed for 1 minute.

| note | If the MIL is illuminated during Steps (1) - (3), stop the engine and erase the DTC. And then go to Step (5). |

(2) Suddenly rev the engine from 4,500/min to 5,000 r/min.

(3) Maintain a stable idle speed for 5 minutes.

(4) Confirm the DTC. Finish the inspection if there is not DTC (intermittent malfunction). If the DTC is set, delete the DTC and go to Step (5).

(5) Start the engine, and maintain a stable idle speed for 1 minute.

| note | If the MIL is illuminated during Steps (5) - (7), check the DTC and perform the appropriate troubleshooting based on the DTC. |

(6) Suddenly rev the engine from 4,500/min to 5,000 r/min.

(7) Maintain a stable idle speed for 5 minutes.

(8) Confirm the DTC. Finish the inspection if there is not DTC (intermittent malfunction). If a DTC is set, perform the appropriate troubleshooting based on the DTC.

8.

| note | If the fuel pressure deviates from the standard value, there will be a malfunction shown in the table below. |

| SYMPTOM | PROBABLE CAUSE | REMEDY |

| Low fuel pump (high pressure) delivery pressure | Replace fuel pump (high pressure) |

| Failed fuel pressure sensor | Replace fuel pressure sensor [integrated in the fuel rail (high pressure)] | |

| Fuel pressure too high | Binding relief valve in fuel pump (high pressure) | Replace fuel pump (high pressure) |

| Failed fuel pressure sensor | Replace fuel pressure sensor [integrated in the fuel rail (high pressure)] |

9. Disconnect scan tool (M.U.T.-IIISE).

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)