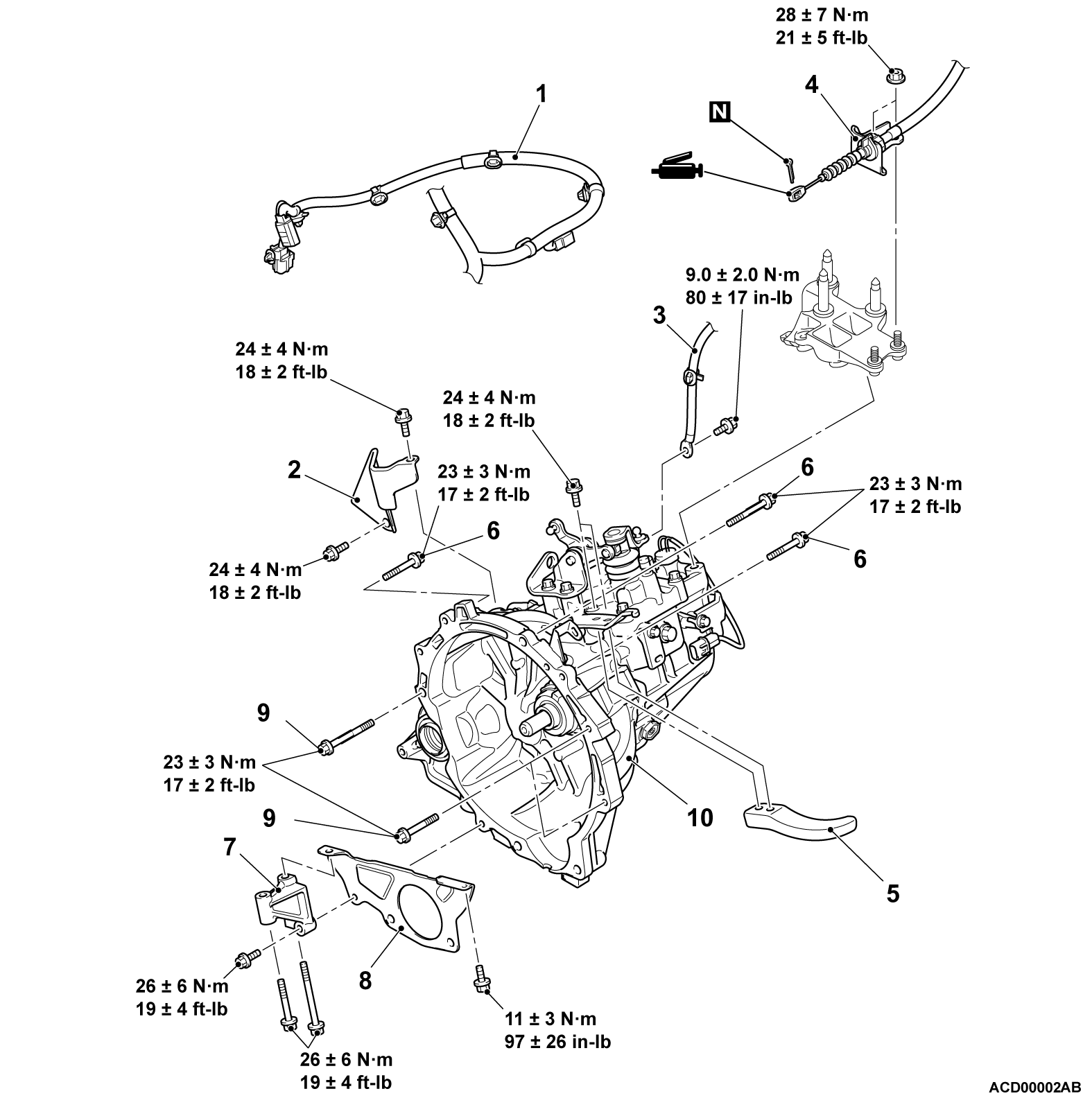

REMOVAL AND INSTALLATION

Required Special Tools:

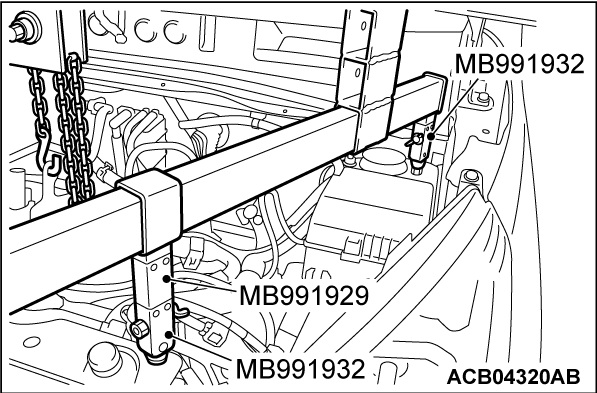

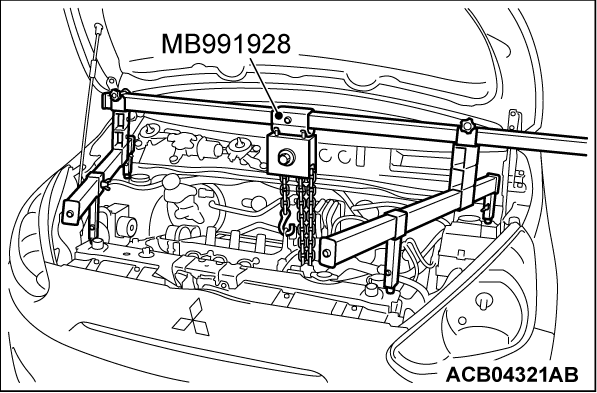

- MB991928: Engine Hanger

- Slide Bracket (HI)

- MB991932: Foot (standard)

- MB991929: Joint (50)

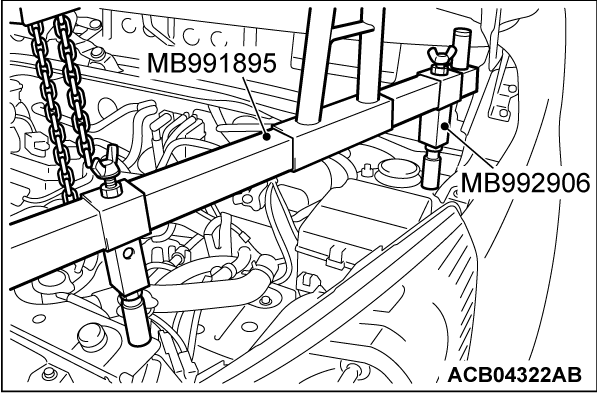

- MB991895: Engine Hanger

- MB992906: Engine Hanger Attachment

REMOVAL SERVICE POINTS

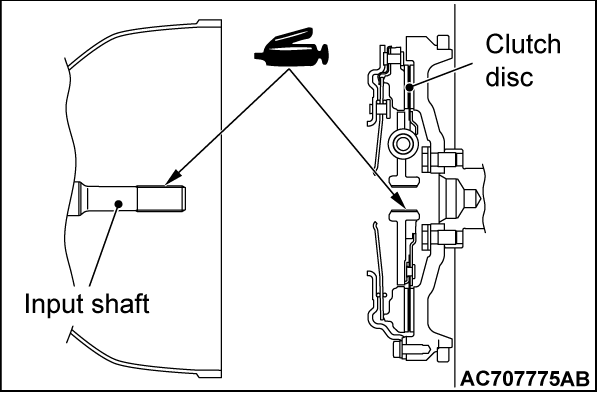

<<A>> TRANSAXLE ASSEMBLY UPPER PART COUPLING BOLTS REMOVAL

Only loosen the each bolt from the engine and transaxle assembly (do not remove).

<<B>> ENGINE ASSEMBLY SUPPORTING

1. <When engine hanger special tool (MB991928) is used>

(1) Assemble the engine hanger special tools (MB991928, MB991932 and MB991929) and slide bracket (HI) (Set the components below to the base hanger).

- Slide bracket (HI)

- Foot x 4 (standard) (MB991932)

- Joint x 2 (50) (MB991929)

(2) Set the special tools MB991928, MB991932 and MB991929 as shown in the figure.

| note | Adjust the engine hanger balance. |

(3) Remove the garage jack and then remove the transaxle assembly upper part coupling bolts that have been loosened previously.

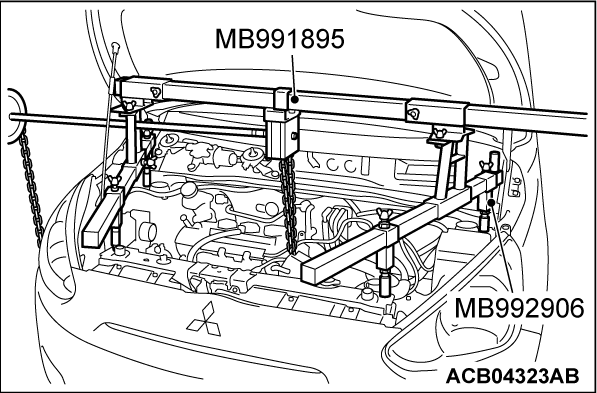

2. <When engine hanger special tool (MB991895) and engine hanger attachment special tool(MB992906) are used>

(1) Set the special tools MB991895 and MB992906 as shown in the figure.

| note | Adjust the engine hanger balance. |

(2) Remove the garage jack and then remove the transaxle assembly upper part coupling bolts that have been loosened previously.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)