REMOVAL AND INSTALLATION

Required Special Tools:

- MB991928: Engine Hanger

- Slide Bracket (HI)

- MB991932: Foot (standard)

- MB991929: Joint (50)

- MB991895: Engine Hanger

- MB992906: Engine Hanger Attachment

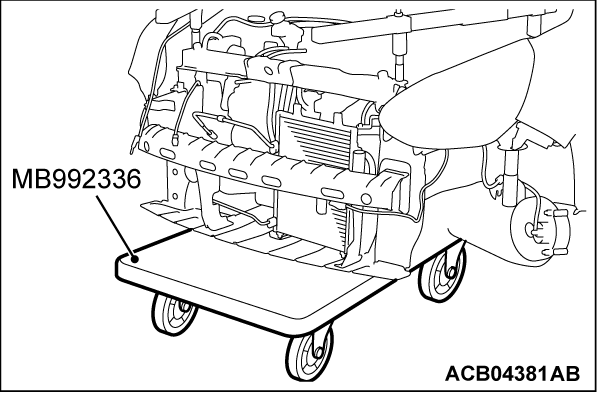

- MB992336: EV Battery Cart

REMOVAL SERVICE POINTS

<<A>> A/C COMPRESSOR AND CLUTCH ASSEMBLY REMOVAL

1. Remove the A/C compressor and clutch assembly together with the hose from the bracket.

2. Tie the removed A/C compressor and clutch assembly with a string at a position where they will not interfere with the removal and installation of engine and transaxle assembly.

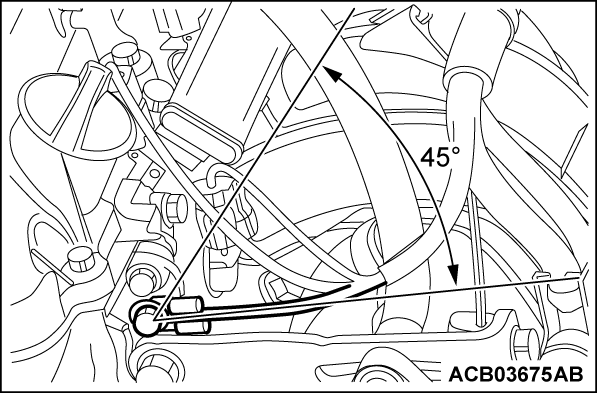

<<B>> ENGINE MOUNTING INSULATOR/TRANSAXLE MOUNTING INSULATOR REMOVAL

1. Secure the engine hanger special tool (MB991928 or MB991895) for holding the engine and transaxle assembly (Refer to GROUP 22A, Transaxle Assembly  ) <M/T> or (Refer to GROUP 23A, Transaxle Assembly

) <M/T> or (Refer to GROUP 23A, Transaxle Assembly  ) <CVT>.

) <CVT>.

) <M/T> or (Refer to GROUP 23A, Transaxle Assembly

) <M/T> or (Refer to GROUP 23A, Transaxle Assembly  ) <CVT>.

) <CVT>.2. Adjust the engine hanger special tool (MB991928 or MB991895) not to allow the weight of the engine and transaxle assembly to rest on the engine mounting insulator and transaxle mounting insulator. Then remove the engine mounting insulator and transaxle mounting insulator.

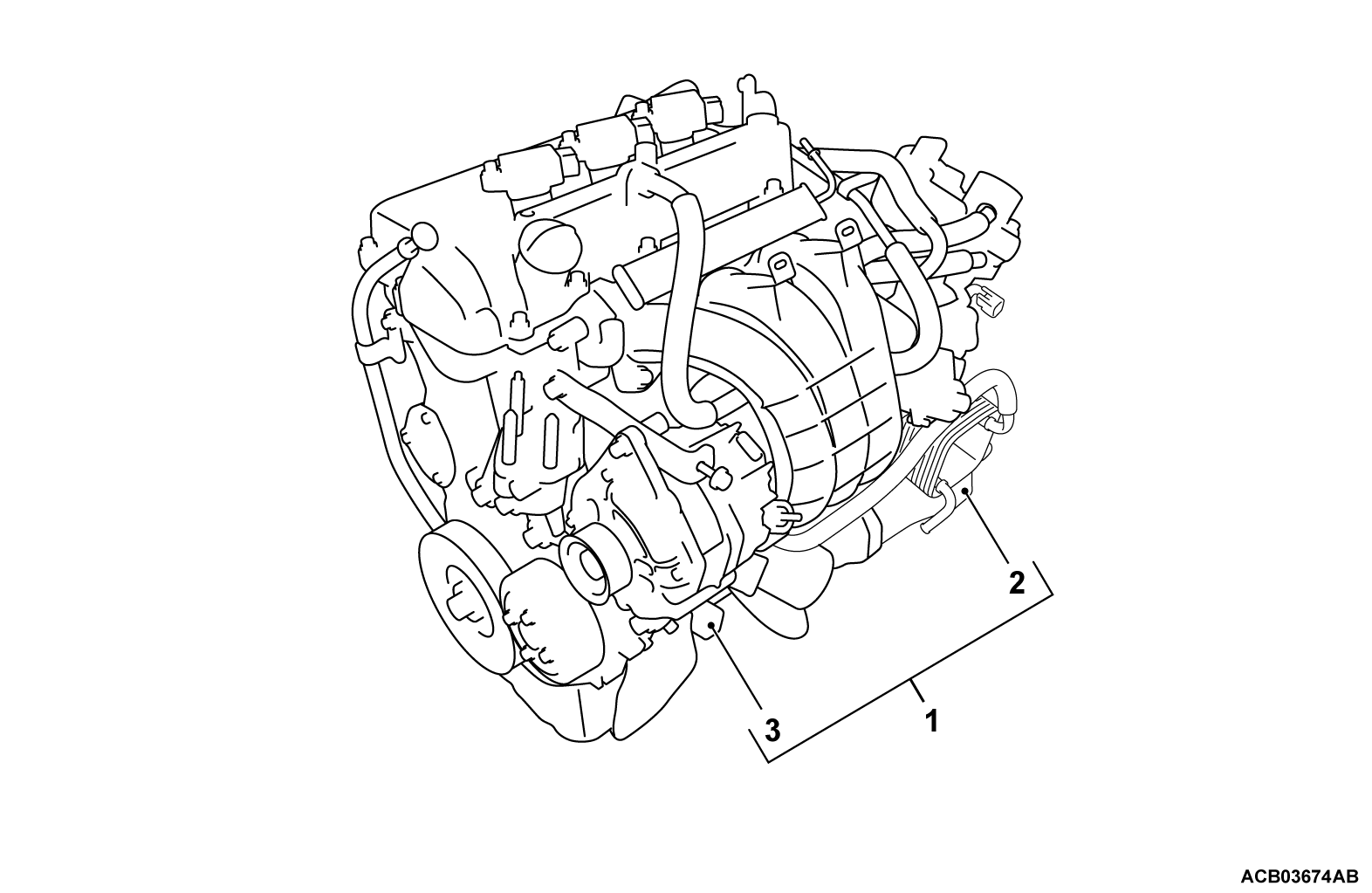

<<C>> ENGINE AND TRANSAXLE ASSEMBLY REMOVAL

1. Place the special tool MB992336 below the engine and transaxle assembly.

2.

| caution | When supporting the engine and transaxle assembly with special tool, be careful not to deform the oil pan. |

Place the special tool MB992336 against the oil pan with a piece of wood in between to support the engine and transaxle assembly.

3. Remove the engine hanger special tool (MB991928 or MB991895).

4. Confirm that the cable, the hose and the harness connector are all disconnected.

5.

| caution | Do not bend the fuel main pipe. |

Raise the body slowly with a lift, and remove the engine and transaxle assembly.

INSTALLATION SERVICE POINTS

>>A<< ENGINE AND TRANSAXLE ASSEMBLY INSTALLATION

Use the special tool MB992336 as during removal to install the engine and transaxle assembly.

>>B<< TRANSAXLE MOUNTING INSULATOR/ENGINE MOUNTING INSULATOR INSTALLATION

Use the engine hanger special tool (MB991928 or MB991895) as during removal to install the transaxle mounting insulator and engine mounting insulator.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)