DTC B1476: IG1 power supply open circuit (Fuse No. 15 circuit)

DTC B1477: IG1 power supply open circuit (Fuse No. 21 circuit)

DTC B1477: IG1 power supply open circuit (Fuse No. 21 circuit)

| caution | If DTC B1476 (fuse No. 15) or B1477 (fuse No. 21) is stored in the SRS-ECU, be sure to diagnose the CAN bus line. |

CIRCUIT OPERATION

SRS-ECU has two independent battery power supplies circuit (fuse Nos. 15 and 21) having fuses.

DTC SET CONDITIONS

The code is stored when the voltage between the IG1 terminal (SRS-ECU terminal IG1A or No. IG1B) and the ground drops below the specified value for 5 seconds continuously. Also, if code No. B1476 and B1477 are stored at the same time, the battery voltage may have dropped. Therefore, check the battery first.

TROUBLESHOOTING HINTS

- Open circuit to power supply circuit

- Damaged wiring harness and connectors

- Malfunction of SRS-ECU

- Malfunction of ETACS-ECU

DIAGNOSIS

STEP 2. Fuse open circuit check

(1) Replace the fuse.

(2) Turn the ignition switch to the "ON" position, wait for at least one minute, and then turn the switch OFF.

(3) Check the fuse.

Is the fuse in good condition?

Repair the wiring harness IG1A line between the junction block connector and the SRS-ECU connector <fuse No. 15>, IG1B line between the junction block connector and the SRS-ECU connector <fuse No. 21> and replace the power supply fuse.

Repair the wiring harness IG1A line between the junction block connector and the SRS-ECU connector <fuse No. 15>, IG1B line between the junction block connector and the SRS-ECU connector <fuse No. 21> and replace the power supply fuse.STEP 3. Using scan tool (M.U.T.-III), diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the CAN bus line found to be normal?

STEP 4. Using scan tool (M.U.T.-III), check data list.

(1)

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Check the ETACS data list.

- Turn the ignition switch to the "ON" position.

|

OK: Normal condition is displayed.

Is the check result normal?

STEP 5. Recheck for diagnostic trouble code.

Check again if the DTC is stored.

(1) Erase the DTC.

(2) Turn the ignition switch to the "ON" position.

(3) Check if the DTC is stored.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the DTC stored?

STEP 6. Resistance measurement at the SRS-ECU connector.

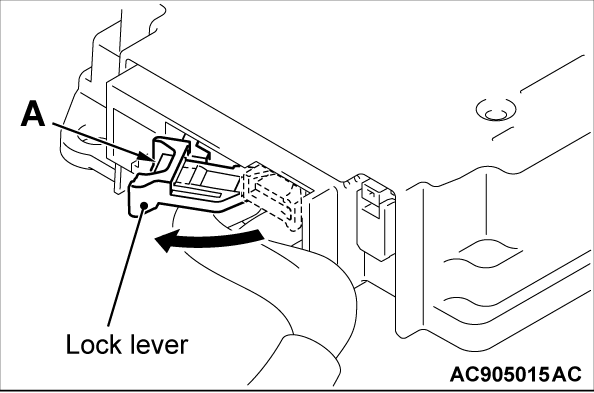

(1) While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the SRS-ECU connectors.

(2) Take the measurements below at the wiring harness side connectors.

- Continuity GND1 line between wiring harness side connector and body ground

OK: Continuity (less than 2 Ω)

Is the check result normal?

Repair the wiring harness GND1 line between the SRS-ECU connector and the body ground.

Repair the wiring harness GND1 line between the SRS-ECU connector and the body ground.STEP 7. Voltage measurement at the SRS-ECU connector (IG1A, IG1B line).

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the SRS-ECU connector.

(3) Connect the negative battery terminal.

(4) Ignition switch: ON

(5) Take the measurements below at the harness side connector.

- Voltage IG1A, IG1B line between SRS-ECU connector and body ground

OK: 9 V or more

(6) Disconnect the negative battery terminal.

Is the check result normal?

STEP 8. Resistance measurement at the SRS-ECU connector.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) Disconnect the junction block connector.

(3) While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the SRS-ECU connector.

(4)

- Continuity IG1A line between junction block connector and SRS-ECU connector

- Continuity IG1B line between junction block connector and SRS-ECU connector

OK: Continuity (less than 2 Ω)

Is the check result normal?

Repair the wiring harness IG1A line between the junction block connector and the SRS-ECU connector, IG1B line between the junction block connector and the SRS-ECU connector.

Repair the wiring harness IG1A line between the junction block connector and the SRS-ECU connector, IG1B line between the junction block connector and the SRS-ECU connector.STEP 9. Recheck for diagnostic trouble code.

Check again if the DTC is stored.

(1) Erase the DTC.

(2) Turn the ignition switch to the "ON" position.

(3) Check if the DTC is stored.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC B1476 or B1477 stored?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)