DTC P0876: Malfunction of high clutch oil pressure switch

DIAGNOSTIC FUNCTION

The TCM checks whether the high clutch oil pressure switch turns ON and OFF normally depending on the hydraulic pressure applied to the high clutch.

DESCRIPTIONS OF MONITOR METHODS

- The TCM determines that a malfunction exists if the high clutch oil pressure switch does not turn OFF when the command pressure to the high clutch is 0 MPa (0 psi) or less, or does not turn ON when the command pressure is 0.2 MPa (29 psi) or more for a certain period.

MONITOR EXECUTION (STUCK ON)

- The target pressure for the high clutch and reverse brake solenoid valve is 0 MPa (0 psi) or less.

- Target auxiliary gear position: 1st

- Engine speed: 450 r/min or more

MONITOR EXECUTION (STUCK OFF)

- The target pressure for the high clutch and reverse brake solenoid valve is 0.2 MPa (29 psi) or more.

- Target auxiliary gear position: 2nd

- Transmission range: "D" or "L"

- Accelerator pedal opening angle: 7.8 percent or more

- Engine speed: 450 r/min or more

- Output shaft speed: 300 r/min or more

- Secondary pulley speed: 300 r/min or more

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0705: Malfunction of the transmission range switch

- P0711, P0712, P0713: Malfunction of transmission fluid temperature sensor

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of the output speed sensor

- P0746: Abnormality in hydraulic control system

- P0791: Malfunction of the secondary pulley speed sensor

- P0962, P0963: Malfunction of the line pressure solenoid valve

- P0973, P0974: Malfunction of the low brake solenoid valve

- P0976, P0977: Malfunction of the high clutch and reverse brake solenoid valve

- P2857: 1st gear neutral malfunction

- P2858: 2nd gear neutral malfunction

- P2859: 1st gear ratio malfunction

- P285A: 2nd gear ratio malfunction

- U0001: Malfunction of CAN communication

- U0100: CAN time-out error (engine)

Sensor (The sensor below is determined to be normal)

- Transmission range switch

- Primary pulley speed sensor

- Output speed sensor

- Secondary pulley speed sensor

- Line pressure solenoid valve

- Low brake solenoid valve

- High clutch and reverse brake solenoid valve

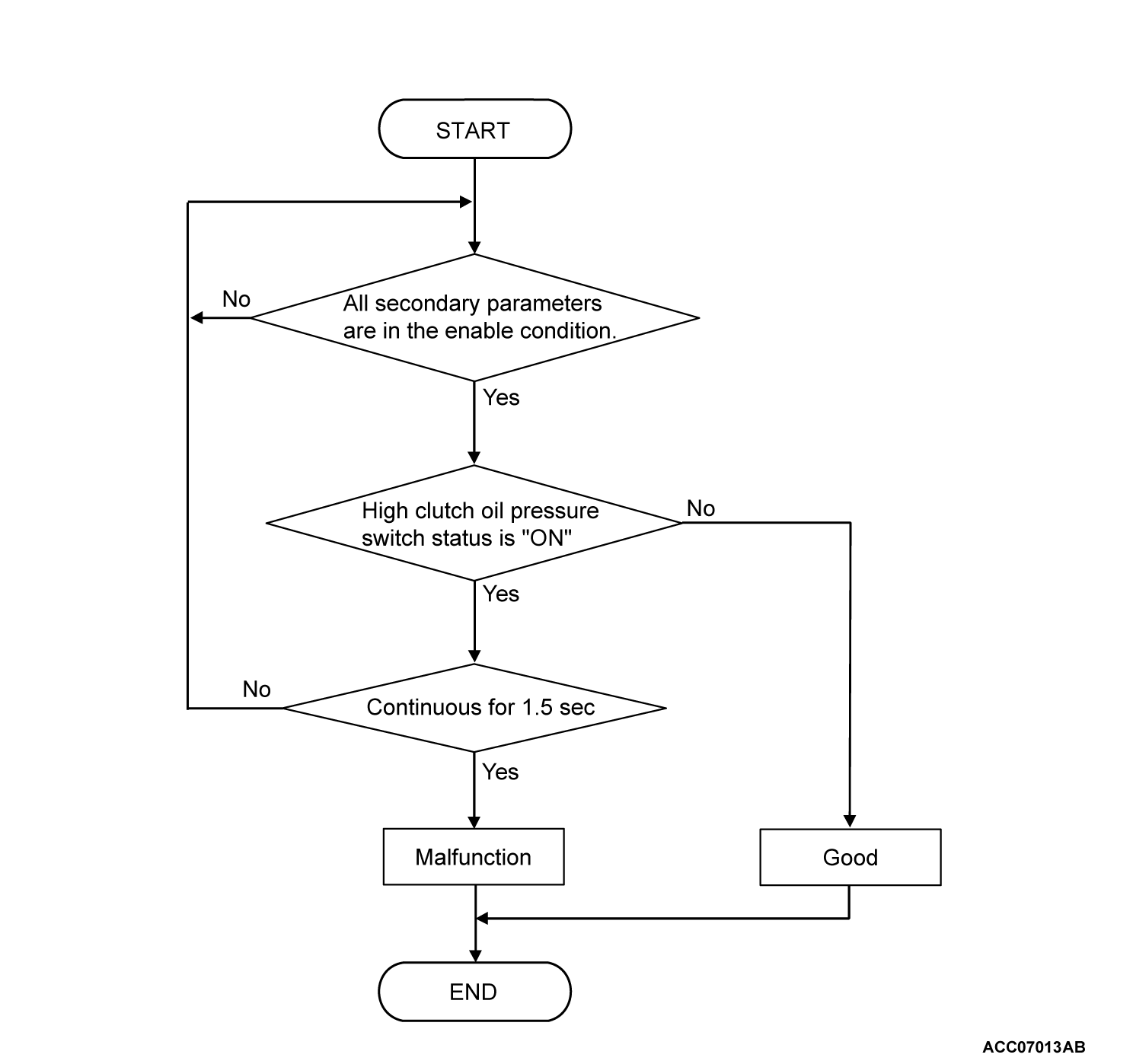

DTC SET CONDITIONS (Stuck ON)

Check Conditions

- The target pressure for the high clutch and reverse brake solenoid valve is 0 MPa (0psi) or less.

- Target auxiliary gear position: 1st

- Engine speed: 450 r/min or more

Judgment Criteria

- The high clutch oil pressure switch is ON for 1.5 seconds.

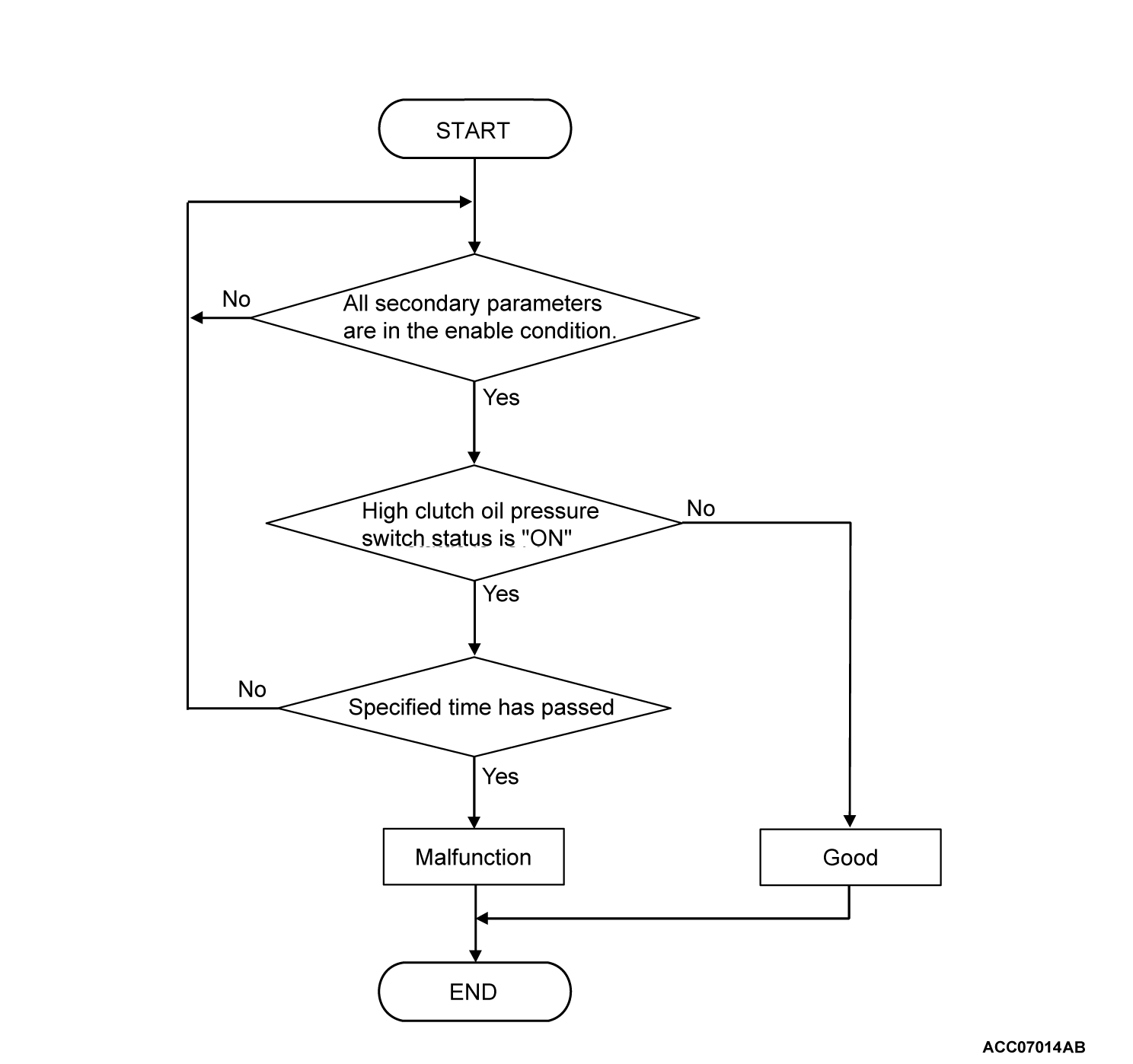

DTC SET CONDITIONS (Stuck OFF)

Check Conditions

- The target pressure for the high clutch and reverse brake solenoid valve is 0.2 MPa (29 psi) or more.

- Target auxiliary gear position: 2nd

- Transmission range: "D" or "L"

- Accelerator pedal opening angle: 7.8 percent or more

- Engine speed: 450 r/min or more

- Secondary pulley speed: 300 r/min or more

- Output speed: 300 r/min or more

Judgment Criteria

- The high clutch oil pressure switch remains off for a certain period. The period depends on transmission fluid temperature. For example, 2.5 seconds at 40°C (104°F) or more, and 10.2 seconds at -20°C (-4°F) or less.

OBD-II DRIVE CYCLE PATTERN

Wait for at least 5 seconds after the engine is started. Then accelerate to 70 km/h (43.5 mph) slowly with the accelerator opening angle at 10 percent or more.

PROBABLE CAUSES

- Malfunction of the valve body assembly (Defective high clutch oil pressure switch)

- Damaged wiring harness and connectors

- Malfunction of TCM

DIAGNOSIS

STEP 1. Check the following connector.

- CVT assembly connector

- TCM connector

Check the terminals for a contact status problem and internal short circuit.

Is the check result normal?

Repair the defective connector.

Repair the defective connector.STEP 2. Check for open circuit or short to ground in ROM3 line between the CVT assembly connector and the TCM connector.

STEP 3. Check for short to other harness in ROM3 line between the CVT assembly connector and the TCM connector.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)