DTC P0328: Knock Sensor Circuit High

CIRCUIT OPERATION

- The knock sensor signal terminal sends a signal voltage to the ECM terminal K/S.

- The knock sensor ground terminal is grounded with ECM terminal K/SE.

TECHNICAL DESCRIPTION

- The knock sensor converts the vibration of the cylinder block into a voltage and outputs it.

- The ECM checks whether the voltage is within a specified range.

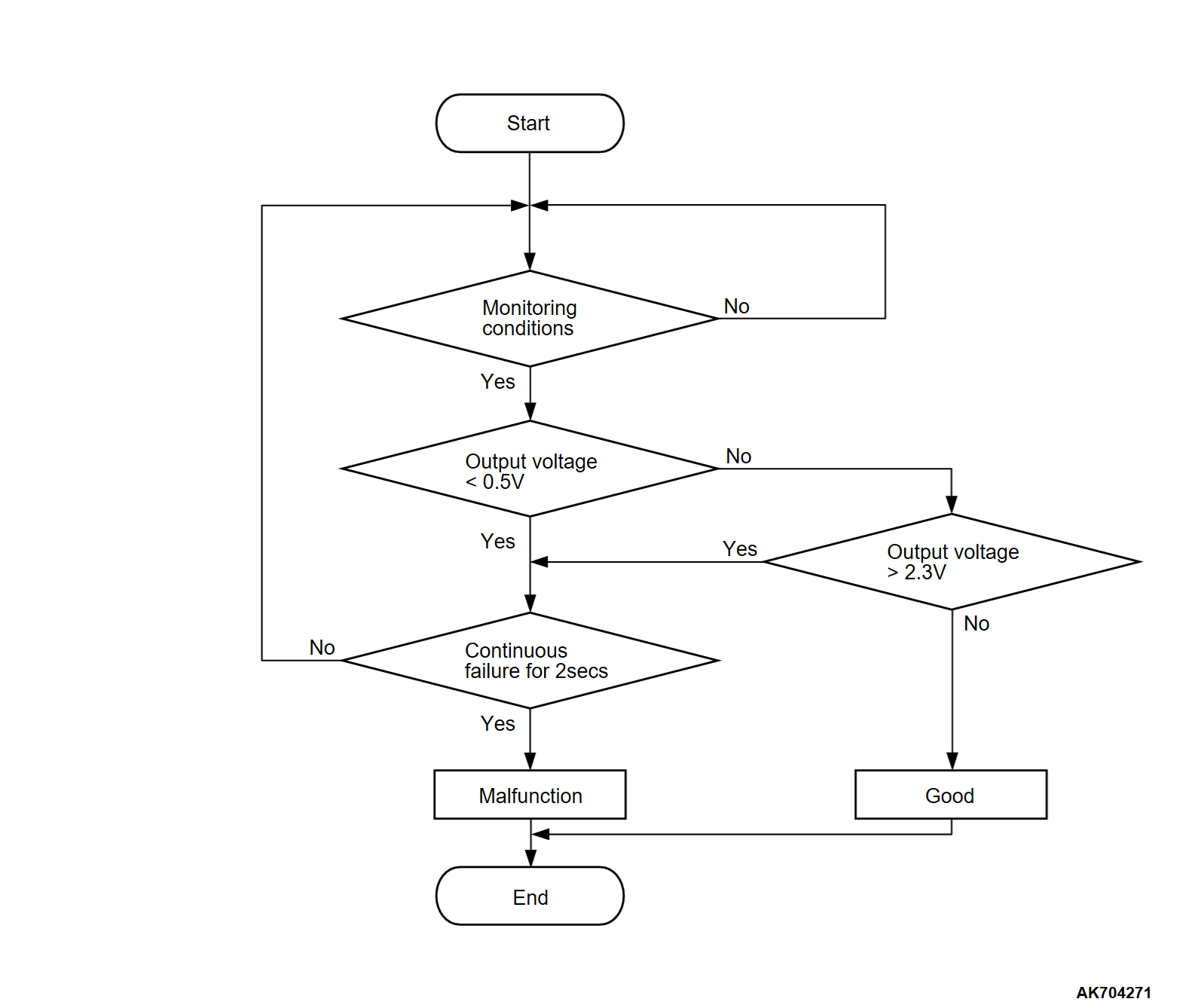

DESCRIPTIONS OF MONITOR METHODS

- Knock sensor output voltage is out of specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Condition

- More than 2 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- Knock sensor output voltage is more than 2.3 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Fix the ignition timing with an allowance against knock.

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are:)

- Shorted knock sensor circuit or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

STEP 1. Check of short circuit to power supply in K/S line between knock sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 2. Check of short circuit to power supply in K/SE line between knock sensor connector and ECM connector.

Is the harness wire in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)