DTC P0507: Idle Control System RPM Higher Than Expected

TECHNICAL DESCRIPTION

- The amount of air taken in during idling is regulated by the opening and closing of the throttle valve.

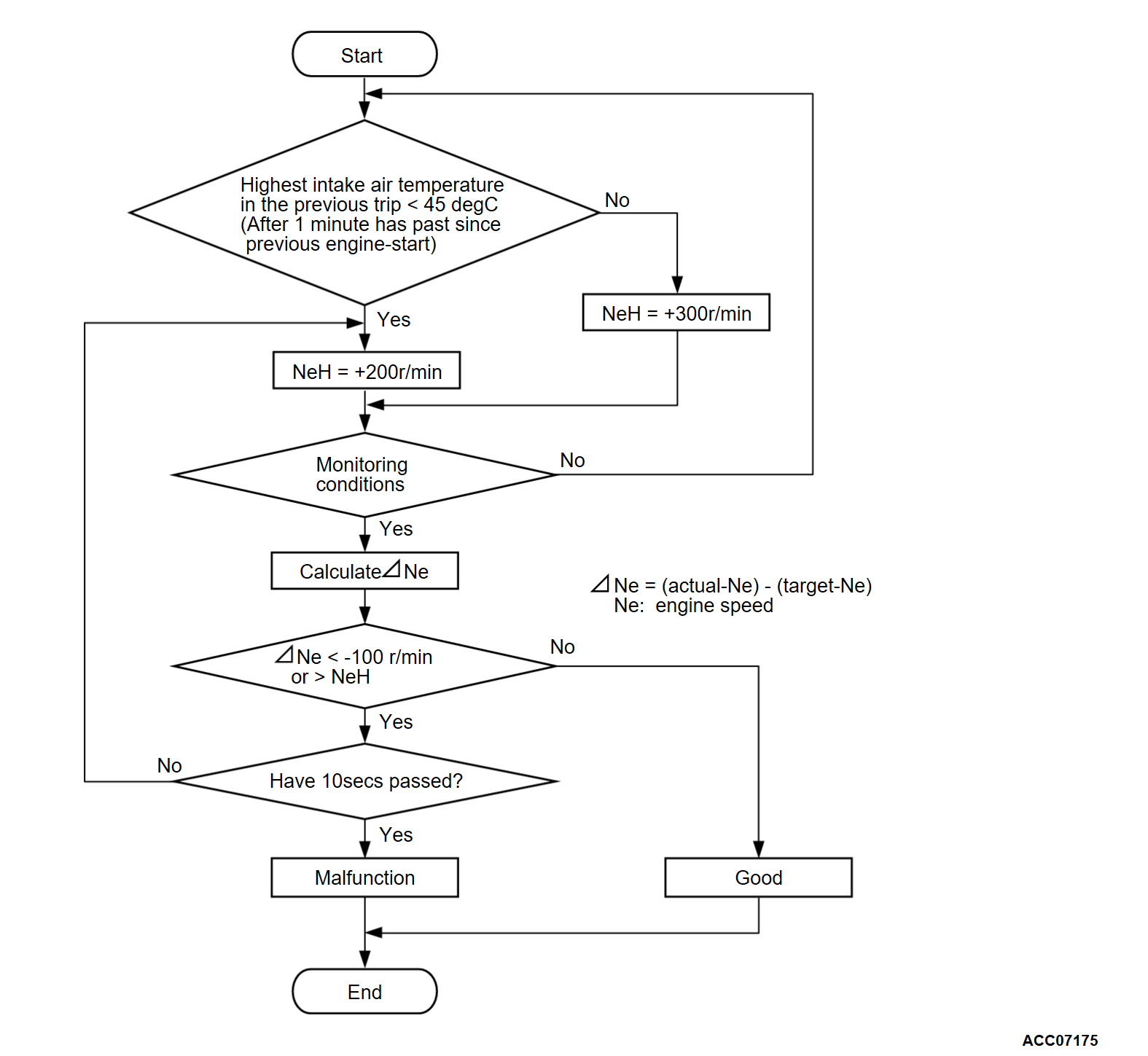

- The ECM checks the difference between the actual engine speed and the target engine speed.

DESCRIPTIONS OF MONITOR METHODS

- Difference between actual and target idle speed is over the specified value.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Misfire monitor

- Fuel system monitor

- Vehicle speed sensor monitor <M/T>

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

Check Conditions

- Under the closed loop idle speed control.

- Engine coolant temperature is more than 41°C (106°F).

- Battery positive voltage is more than 10 volts.

- Barometric pressure is more than 76 kPa (22.4 in.Hg).

- Intake air temperature is more than -10°C (14°F).

- More than 3 seconds have passed from the end of the previous monitoring.

- Target airflow rate is 0 g/sec (0 L/sec).

Judgment Criterion

- The actual idle speed is more than the target idle speed by 203 r/min (305 r/min*) or more for 10 seconds.

- *: Specs in parentheses are applicable if the maximum intake air temperature during the previous operation was more than 45°C (113°F).

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are:)

- Intake system vacuum leak.

- Throttle body assembly failed.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

STEP 1. Using scan tool (M.U.T.-III), read the diagnostic trouble code (DTC).

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Turn the ignition switch to the "ON" position.

(3) Read the DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the diagnostic trouble code other than P0507 stored?

STEP 2. Check for intake system vacuum leak.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)