DRIVE BELT TENSION CHECK AND ADJUSTMENT

DRIVE BELT TENSION CHECK

| caution |

|

Check the drive belt tension in the following procedure.

| note | For the vehicles without A/C, the check procedure is also same. |

Standard value:

|

| note |

|

<When the vibration frequency is measured: Recommendation>

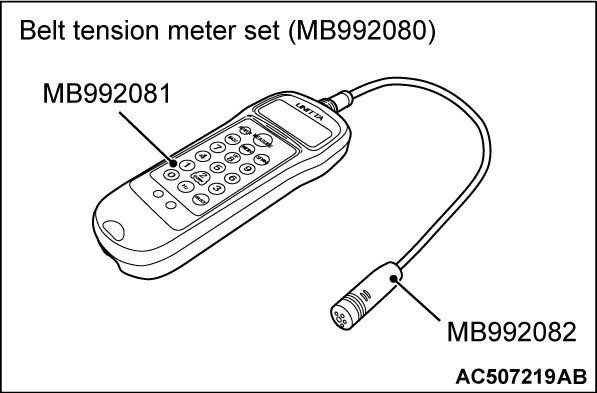

1. Connect special tool microphone assembly (MB992082) to special tool belt tension meter (MB992081) of special tool belt tension meter set (MB992080).

2. Press the "POWER" button to turn on the power supply.

3. Press number key "1". Check to ensure that "No. 01" appears on the upper left of the display and that the following numeric values are displayed for individual items ("M", "W", and "S"):

M 000.9 g/m

W 010.0 mm/R

S 0100 mm

| note | If numeric values have not been entered (new tool), set them according to the belt specifications as shown below. Once you set them, you do not have to set them again. The settings remain undeleted even after battery replacement. |

| note | This operation is to temporarily set the preset data such as the belt specifications, because if the measurement is taken without input of the belt specifications, conversion to tension value (N) cannot be made, resulting in judgment of error. |

<Setting procedure>

(1) Press down the "MASS" button till the belt mass select display appears.

(2) Press the "UP" or "DOWN" button to select "01 1.5GT 0.9" and press the "MEASURE" button to decide it.

Check to ensure that "M 000.9 g/m" is displayed.

(3) Press the "WIDTH" button to change to the belt width input display.

(4) Press number keys "0", "1", "0", and "0" sequentially, and press the "SELECT" button to apply them. Check to ensure that "W 010.0 mm/R" appears on the display.

(5) Press the "SPAN" button to change to the span length input display.

(6) Press number keys "0", "1", "0", and "0" sequentially, and press the "SELECT" button to apply them. Check to ensure that "S 0100 mm" appears on the display.

4. Press "Hz" button twice to change the display to the frequency display (Hz).

5.

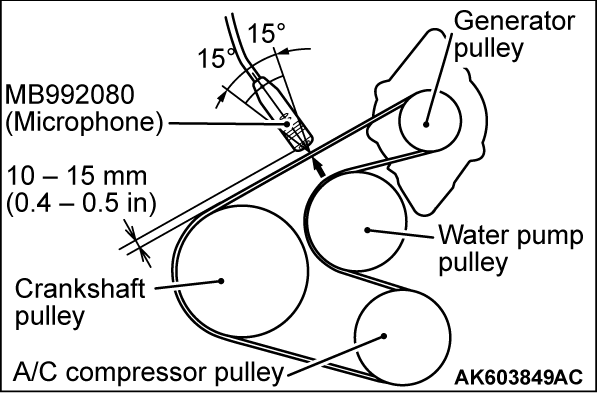

Hold special tool MB992080 to the middle of the drive belt between the pulleys (at the place indicated by arrow) where it does not contact the drive belt [approximately 10 - 15 mm (0.4 - 0.5 inch) away from the rear surface of the belt] so that it is perpendicular to the drive belt (within an angle of ± 15°).

| caution |

|

6. Press the "MEASURE" button.

7. Gently tap the middle of the drive belt between the pulleys (the place indicated by the arrow) with your finger as shown in the illustration.

8. Check that the vibration frequency of the drive belt is within the standard value.

| note | To take the measurement repeatedly, fillip the drive belt again. |

9. After the completion of the measurement, press and hold the "POWER" button to turn off the power supply.

<When tension is measured>

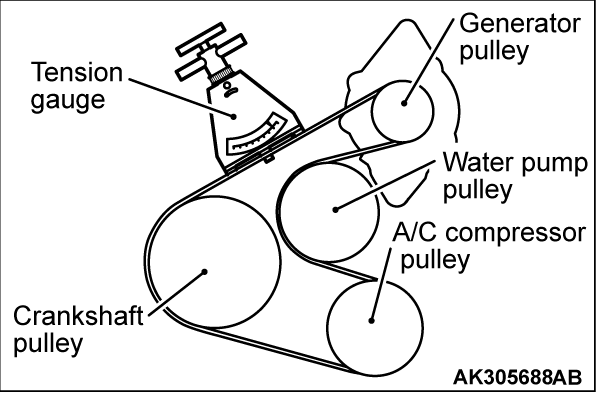

Use a belt tension gauge in the middle of the drive belt between the pulleys shown in the figure to check that the drive belt tension is within the standard value.

| note | Before inspection, remove the oil dipstick guide assembly (Refer to  ). ). |

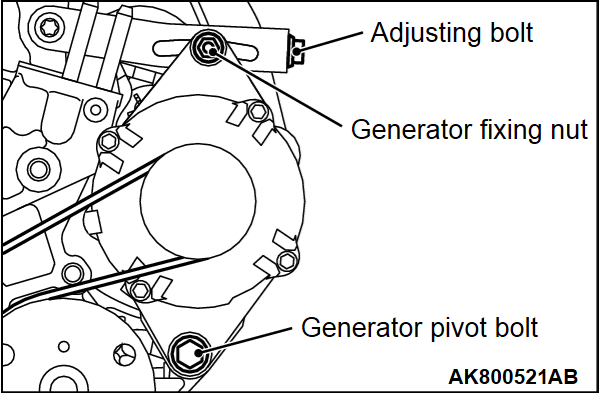

DRIVE BELT TENSION ADJUSTMENT

If not within the standard value, adjust the belt tension by the following procedure.

1. Loosen the nut for generator pivot bolt.

2. Loosen the generator fixing nut.

3. Temporarily tighten the generator fixing nut.

Tightening torque: 10 ± 3 N·m (89 ± 26 in-lb)

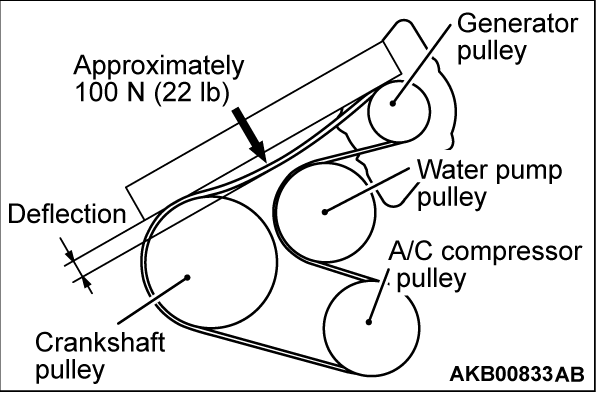

4. Use the adjusting bolt to adjust the belt tension and belt deflection to the standard values.

5. Tighten the nut for generator pivot bolt.

Tightening torque: 47 ± 5 N·m (35 ± 3 ft-lb)

6. Tighten the generator fixing nut.

Tightening torque: 23 ± 2 N·m (17 ± 1 ft-lb)

7. Tighten the adjusting bolt.

Tightening torque: 5.0 ± 1.0 N·m (44 ± 8 in-lb)

8.

| caution | When checking the belt tension, turn the crankshaft clockwise one turn or more. |

Check the belt tension, and readjust if necessary.

9. When the belt tension is adjusted by measuring the deflection, adjust it with a tool for vibration frequency measurement or tension measurement afterward.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)