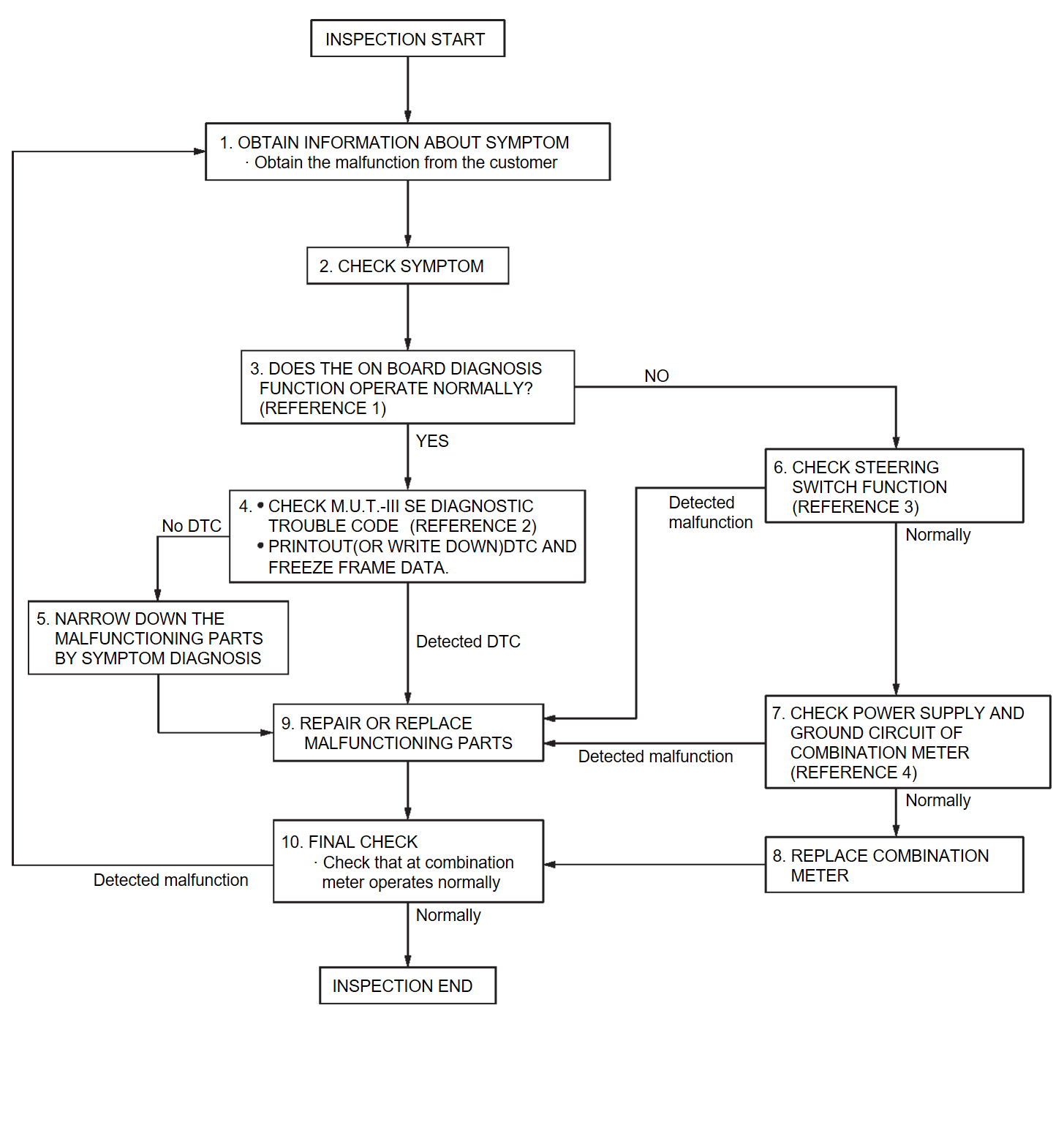

Work flow

OVERALL SEQUENCE

- Reference 1···On Board Diagnosis Function

.

. - Reference 2···DTC Index

.

. - Reference 3···Component Function Check

.

. - Reference 4···Diagnosis Procedure

.

.

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check that any other malfunctions are present.

3.CHECK ON BOARD DIAGNOSIS OPERATION

Check that the on board diagnosis function operates. Refer to On Board Diagnosis Function .

.

.

. Does the on board diagnosis function operate normally?

4.CHECK M.U.T.-III SE DIAGNOSTIC TROUBLE CODE RESULTS

- Connect M.U.T.-III SE and perform Diagnostic Trouble Code. Refer to DTC Index

.

. - When DTC is detected, follow the instructions below:

- Record DTC and Freeze Frame Data.

Are Diagnostic Trouble Code results normal?

5.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

6.CHECK STEERING SWITCH FUNCTION

7.CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Check combination meter power supply and ground circuits. Refer to Diagnosis Procedure .

.

.

. Is inspection result normal?

9.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the malfunctioning parts.

| note | If DTC is displayed, erase DTC after repair or replace malfunctioning parts. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)